ESDEP WG 15A

STRUCTURAL SYSTEMS: OFFSHORE

To elaborate on structural steel concepts for integrated decks, module support frames, and modules. To show principles and methods of construction (from yard to offshore site).

Lectures 1A & 1B: Steel Construction

Lecture 2.4: Steel Grades and Qualities

Lecture 2.5: Selection of Steel Quality

Lectures 3.1: General Fabrication of Steel Structures

Lecture 6.3: Elastic Instability Modes

Lecture 7.6: Built-up Columns

Lectures 8.4: Plate Girder Behaviour and Design

Lecture 11.2: Welded Connections

Lecture 12.2: Advanced Introduction to Fatigue

Lecture 15A: Offshore Structures

Structural systems for each type of topside structure are introduced, i.e. truss, portal frame, box girder, and stressed skin.

Some special topics of design are addressed and the different construction phases are presented in more detail, i.e.:

A brief discussion on inspection and repair and on platform removal concludes this lecture.

This lecture deals with the structural design of jacket-based offshore deck structures, following the introduction in Lecture 15A.10.

Heavy decks, over 10.000 tons, are provided with a module support frame onto which a number of modules are placed, see Lecture 15A.1, Figs. 4 and 5. Smaller decks, such as those located in the southern North Sea, are nowadays installed complete with all equipment in one lift to minimize offshore hook-up. Most of this lecture refers to this type of integrated deck as described in Lecture 15A.10.

The selection of the concept for the structural deck is made in close cooperation with the other disciplines.

For the design of the deck structure, the in-place condition has to be considered, together with the various previous stages such as fabrication, load-out, transport and installation.

A structural system for a deck structure comprises several of the following elements:

| Floors (steel plate or grating) | } | |

| Deck stringer (H beams, bulbs or troughs) | } Discussed in | |

| Horizontal bracing | } Lecture 15A.10 | |

| Deck beams

|

}

|

|

| Primary girders | } | |

| Vertical trusses or bracing | } Discussed in | |

| Deck legs | } this lecture |

Some major topics in topside structural design are reviewed below.

A portal frame design has been used in recent major projects in the Dutch sector such as Amoco P15, Placid K12 [5] and Penzoil L8.

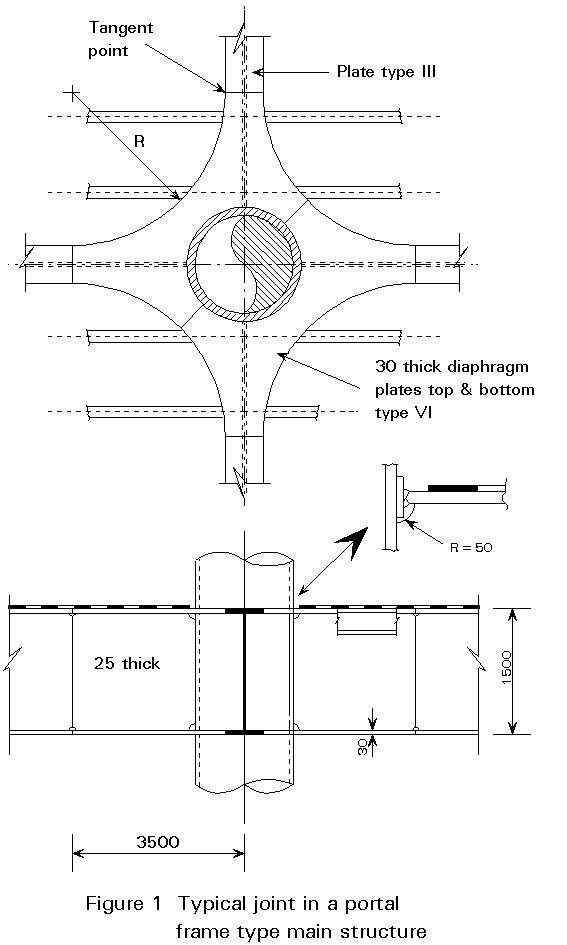

The main girder/column joint, as shown in Figure 1, is very important in determining the height. It is most practical to position the longitudinal and transverse main girder flanges at the same elevation.

Haunching of the transverse main girder , which is more lightly loaded-in-plane, however is not an option as these girders become highly loaded during transport.

The severe restraint of welding a tubular in a diaphragm requires the selection of TTP steel for the column section.

Due to the high importance of the diaphragm plates in the overall integrity of the structure and the welding constraints on the web plates in between, TTP-steel is chosen also for the diaphragm.

Another option is to weld the girders directly onto the unstiffened can section of the column. The assessment of ultimate resistance as well as fatigue strength has been the subject of recent research (see Lecture 15A.12).

Further improvement of the theoretical and experimental background is required. For lighter loaded truss structures, this non-stiffened type of joint has been used successfully.

A third solution is to weld the girders directly to the can section of the column, which is internally stiffened by rings. Its most severe disadvantage is the difficulty of inspecting the column interior.

The disadvantage of both direct girder-column joints is that the girder sizing is governed by the very high moments at the column/beam transition point.

Cast steel nodes form an alternative to the welded designs.

Member selection for portal frame structures with increasing section moduli usually includes:

The plate girder of course provides the greatest flexibility for design, material selection and procurement, though its cost per tonne is approximately twice that of a rolled beam.

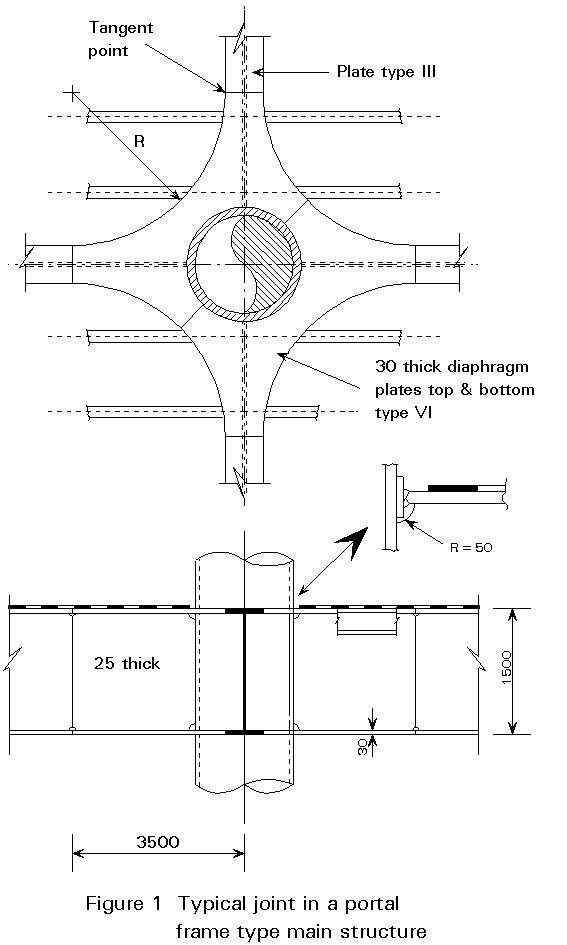

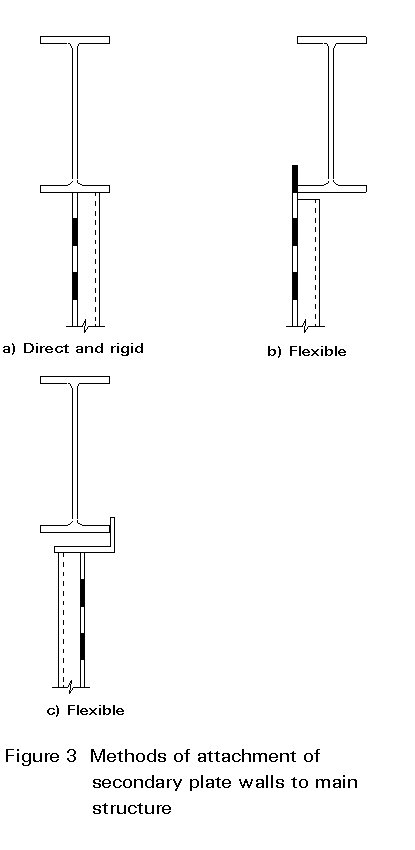

Most offshore structures of moderate size have been provided with a truss-type structure. Typically such trusses consist of rolled beams as chords and tubulars as diagonals.

Truss design requires several choices which affect the structural efficiency and have impact on other disciplines:

Figure 2 shows different arrangements of braces (basically N or W-type) obtained by variation of the number of nodes. It should be kept in mind that all diagonals and verticals form obstructions for piping and cable routings of all kinds.

For the transverse trusses, transparency is even more important, especially near the well area. The number of members required should therefore be reduced to a minimum.

Providing a W-truss with light verticals should be evaluated against choosing a heavier chord section.

If a joint, e.g. at the top deck, is subject to severe moments due to lifting, ventstack, or crane pedestal for example, much of the bracing stress would result from unintended bending. Generally the deck leg restraint creates a similar problem in the lower deck. An evaluation should yield a preferred location therefore for the node of the end brace.

The truss deflects under its vertical load which leads to restraint of the chord in the column and to bending of the chord. Both effects can quite severely effect the efficiency. The chord section should be kept compact therefore and not given too much height.

Tubulars (circular, square or rectangular) or rolled sections can be chosen for the braces.

The choice depends primarily on the loads and the chord width. A chord width of 300mm can accommodate a 10 in. brace only. Thus a wider chord flange is preferred.

A third major structural option is the stressed skin concept, where full height plate walls take the function of the truss or the frame.

Modules for living quarters are frequently built to this concept. Other types of modules have not been built with stressed skin since the obstruction they cause during construction is severe.

For smaller stressed skin modules, trapezoid corrugated plate can be used to provide a wall in a frame of square hollow sections.

For bigger modules, flat plate stiffened with through-stiffeners is used for the walls.

The detailed design can only be made with a clear plan for assembling the module which shows the panels that must be prefabricated.

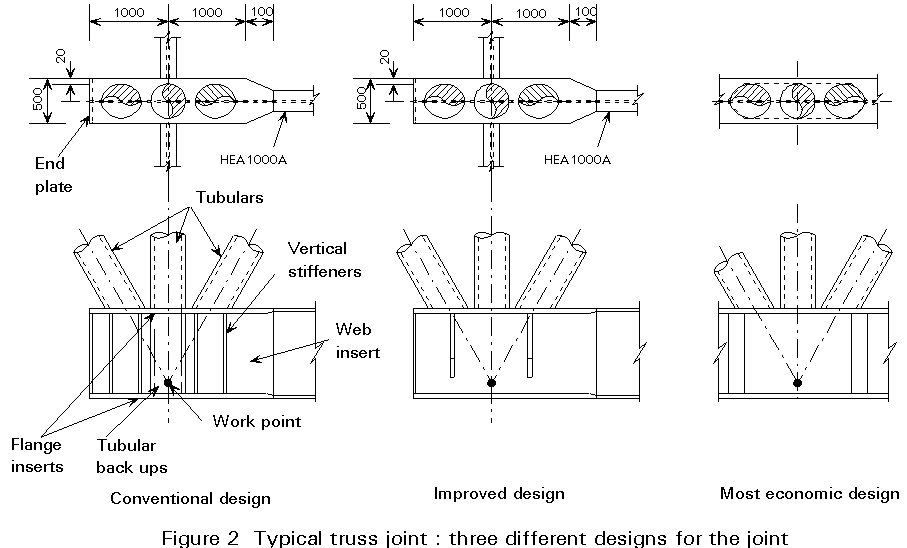

Blast or fire walls are provided in offshore platforms. Due to their function full welding to the main structure is often unavoidable, see Figure 3a.

Special attention is required concerning:

One solution is to provide a flexible detail, see Figure 3b and 3c, with stiffeners falling short.

Crane pedestal, are discussed briefly below.

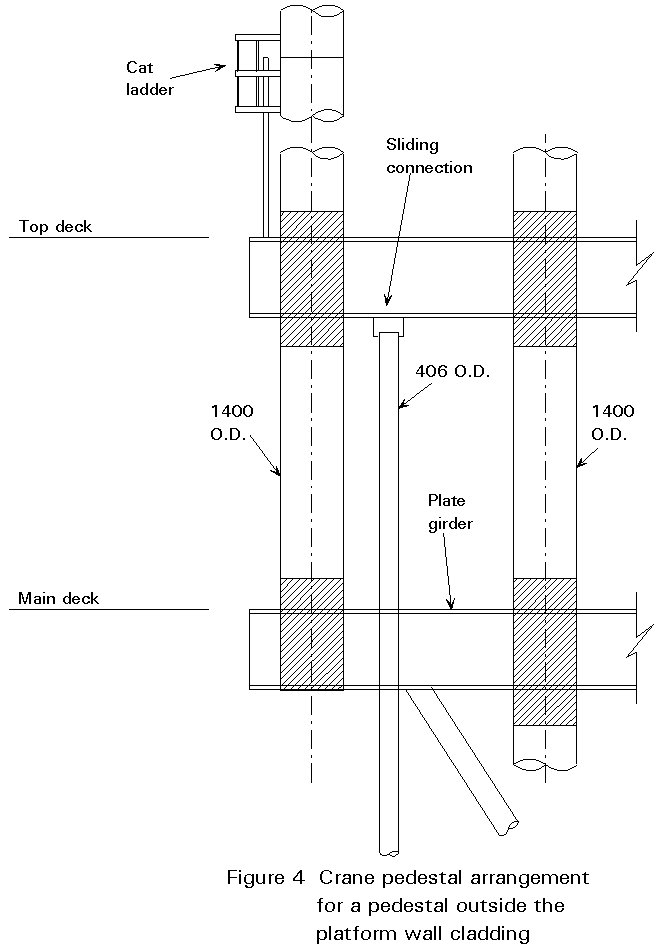

It is structurally economical to put the crane pedestal on top of a main column. For a truss type the main structure will be close to the platform periphery so a moderate length of crane boom is sufficient.

For a portal frame type with columns closer to the outer periphery, the pedestal requires a special column in order to avoid using a crane with large boom length. Figure 4 depicts such a solution.

The functions of the main structure with respect to the crane pedestal are:

Bending restraint by deck beams and/or main structure girders is not required and should be reduced where possible. Torsion caused by slewing of the crane should preferably be resisted by the floor plate, the stiffest element.

It has become practice to include the tapered top section of the pedestal in the supply package of the crane. The top section contains the large flange for the slewing bearing.

Fatigue due to crane operations is a design criterion and requires careful detailing of the pedestal and the adjoining structure.

Although the analysis of deck structures is a standard task, several aspects require special attention:

Design of plate girders requires selection of many dimensional variables and of approaches for assessing load-carrying resistance. Lectures 8.4 deal in more detail with plate girder design.

Web buckling due to bending, normal force and shear restricts the slenderness of the web which is expressed as the height of the web (h) divided by the web thickness (t).

API-RP2A [2] refers to the AISC manual [3] which gives the figures below for material with yield-stress of 355 MPa:

Allowable bending stress 0,66 Fy 0,60 Fy

Ratio web height h to thickness t 90 138

Ratio flange width b to thickness t 18 27

Instead of the above approach, more recent research, [3] and [6], allows use of the post-buckling strength. The depth/thickness limits given above do not then apply.

The most important joints in a topside steel structure are:

These joints are discussed in Lecture 15A.12.

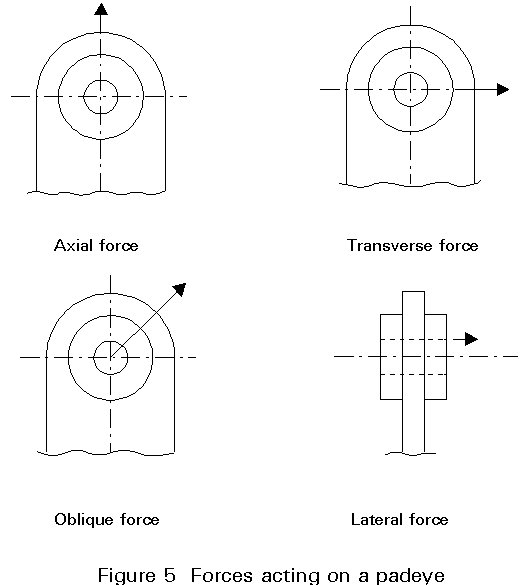

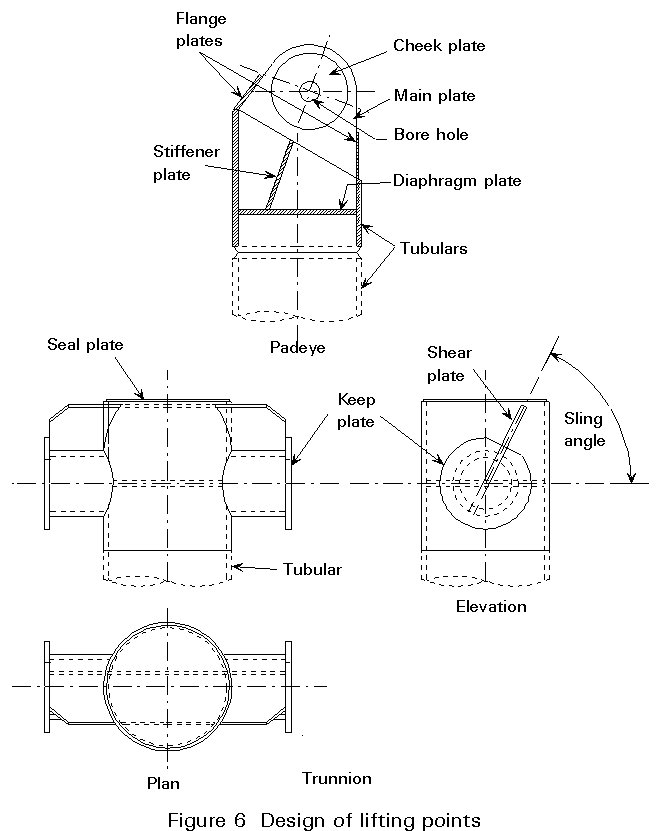

The effect of lifting points on deck design is considerable. For example the local forces that act on the lifting points (Figure 5) have to be transmitted safely through to the deck structure.

There are two types of lifting points, trunnions and padeye, Figure 6.

Trunnions, though favourable from other points of view, see Section 4, can generate considerable offset of the sling force with respect to the topdeck system points. Significant bending is generated which is transferred to the topdeck girders to the extent that they contribute to joint stiffness. It is most efficient to leave these bending moments in the column, by providing stiff columns.

Padeyes generally provide a good opportunity to minimize or eliminate offset, as far as they can be situated on top of the column. The requirement of recessed padeyes (recessed padeyes are those which are positioned between the top and bottom flange elevation) or the presence of other structures on the top deck can lead to very eccentric positioning and resulting heavy moments. For this reason the lifting concept must be developed in the concept phase of the structural development.

API-RP2A [1] requires larger load factors to be used for members direct-loaded by padeyes or trunnions.

There are two points of major interest:

There are several ways to model the plate. The most direct is to choose a computer-program which allows selection of plate elements. A second option is to define representative members which model the plate stiffness by diagonals.

The deck plate is often positioned in the model at the elevation of the centre line, i.e. the mid height of the main structure girders, in order to save nodes in the model. It should however be recognised that this "error" of elevation, amounting to 0,5 - 1m, can affect the results. A separate evaluation should then be performed on the effect to this deliberate "error" at least at some critical points.

Modules and deck structures interact structurally. API-RP2A [1] requires that modules are modelled as elastic structures for the analysis of the supporting deck. In the 1970's major difficulties arose in the decks for concrete gravity structures, because modules were represented as a set of loads for the different load cases, acting at the support points, and neglecting structural interaction. The basic phenomenon of this interaction is that the distribution of the support reactions of the module is quite unequal and varies with the load case. Dimensional control of the module as well as the support, with corrective measures, further provide control over the module - deck interaction. Some modules, such as living quarter modules, gas compressor and injection modules, are often placed on anti-vibration pads in order to isolate them from vibrations.

In Lecture 15A.1 the principal aspects of construction of offshore structures and their major equipment was introduced.

For topsides more specific aspects are discussed below.

The design should allow efficient prefabrication of major sections. Prefabrication will avoid congestion in one working area and it speeds up the whole construction process.

Prefabrication and assembly shall properly incorporate the aspects of installation of major and smaller mechanical equipment, as well as outfitting with piping, electrical and instrument cables and lines. It should be recognized that major mechanical and electrical equipment is often not available at the start of assembly and must be brought in during fabrication.

Since the overhead space is well covered by extensive piping routes as well as cable trays during construction, "late" structural work should preferably not be positioned overhead in that underfloor area.

Fabrication of offshore steel structures is principally assembly by welding.

The prefabrication concept and joint detailing should maximize welding productivity with many horizontal welds preferably made using SMAW technology.

Support to the topside during construction should be well controlled to avoid settlement and to keep within construction tolerances.

Special consideration should be given to the selection of materials suitable for the fabrication. Where thick-walled elements are involved requiring Post Weld Heat Treatment (PWHT), the design should position such welding and the PWHT in the prefabrication phase.

The topside must be kept under strict weight control, as explained in Lecture 15A.10. To that end the topside is usually weighed prior to load out. The basic design of a weighing system usually consists of a set of hydraulic jacks with electrical load cells on top, installed between the topside and the shop floor. The accuracy of such systems is typically 0,5-1%.

Accuracy is necessary in order to check the actual position of the centre of gravity. Knowledge of the position is vital for the installation.

The system for support of the topside should be similar to the anticipated method of load out.

The load out usually combines two operations:

The short journey on land can be complicated when the track is not flat or curves have to be taken.

The most preferred option for load out is therefore to use a platform trailer with individual suspended wheels, see Figure 7 and Slide 1.

Slide 1 : General arrangement of a load out through skidding

The trailer drives from the quay over a rocker flap resting on the quay and the barge and then slowly onto the barge. The barge is kept in right trim by ballast pumping.

When it reached the right position, the topside is set down on the beam grid of the sea fastening.

When using platform trailers the lower deck should be designed to meet three basic load-out requirements:

A uniform distribution of loads is assumed for platform trailers. Skid systems which are not provided with a proper load sharing system will lead to a non-uniform load distribution.

Design for load-out requires coordination with sea fastening design.

Sea transport is a very critical operation, especially for topsides (see Slide 2).

Slide 2 : Seafastening of 105MN Brent C topside

After completion of the load out and full fastening to the barge, the barge is ballasted to its target draft and cleared for the transport.

The barge is towed by one or two tugs to the offshore location. There the barge is positioned close alongside the crane vessel.

Prior to lifting, the sea fastening is cut free.

Planning the sea transport contains several steps:

There is also the option with some crane vessels to transport the top side on board. Usually an extra take over is required as the draft of the crane vessel exceeds the depth at the fabricator's quay. The advantage however is that sea fastening requires less effort. Furthermore, the offshore operation is simpler and quicker, as the most critical and weather sensitive operation - lift off the barge- is avoided.

Several elements of the structure are dominated by the load condition during transport, see Lecture 15A.1.

All equipment in or on the topside is also subject to heavy loads, e.g. control panels, generator skids, platform crane, during transport.

Internal bracing of a topside for transport is not favoured since it creates obstacles and risk of damage or fire to cables, instruments, piping and equipment during subsequent removal. External bracing is also not without problems. The width of the topside requires an extra wide barge. It is difficult to find "strong" points on the topside exterior. The basic concept is therefore to fix the topside to the barge by its columns only.

The designer should be aware that the bending stiffness of the topside often exceeds that of the barge. Considerable "composite" action can result when the barge deflects in heavy head-on seas.

It is very important for any sea fastening concept to consider aspects of de-seafastening, i.e. cutting free, prior to lift off, and the need to remain safe in a moderate sea state.

De-seafastening should not require any handling by cranes. Braces cut loose at one end should therefore remain stable and safe while fixed at one end only.

Design of the sea fastening should not require any welding in the column joint, since the topside would not then be ready for immediate set down onto the jacket.

When the tow is more than one or two days long, fatigue may have to be considered on critical nodes.

Installation on the substructure can be:

Slide 3 : Deckmating of the 500MN Gullfaks-C topside

Slide 4 : Installation of 60MN K12-BP topside by floating crane

Deck mating is a floating operation in a sheltered location, e.g. a Norwegian fjord or Scottish loch. Deck mating requires that the deck is temporarily supported with the final supports free. This requirement creates a very awkward load situation for the deck structure.

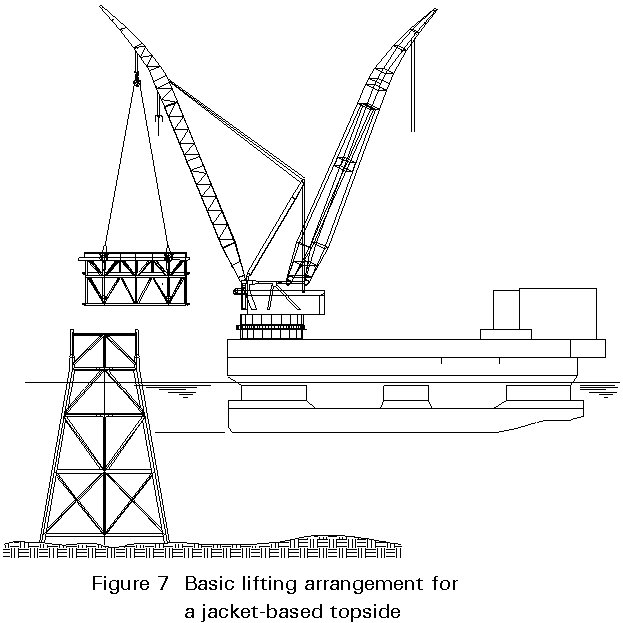

Lifting is the usual installation method for jacket-based topsides. During development of a platform concept, the lift strategy should be defined as part of the overall construction strategy. The lifting capacity of crane vessels is defined by hook-load and reach.

The required reach is determined mainly by the width of the topside and/or the transport barge.

The major steps are:

The lift concept consists of several elements:

Crane vessels were listed in Lecture 15A.1. Slings are available up to over 400mm nominal diameter with safe working loads of 20-25 MN.

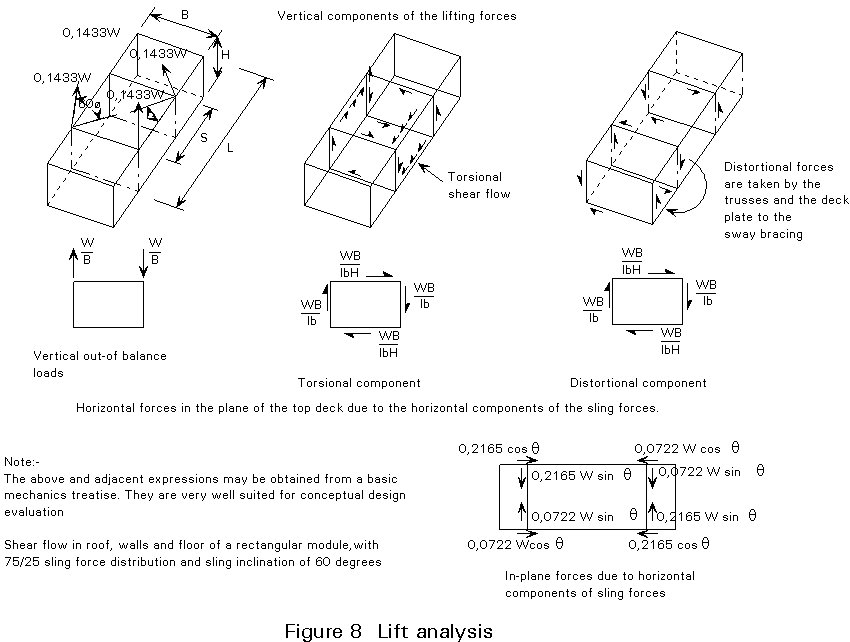

A basic element in all elevations is the inevitable tolerance in sling length which leads to an unequal distribution of sling forces (typically 25%-75%) in a four sling lift. The unequal sling forces lead to significant stresses in the module (see Figure 8).

The use of spreader bars leads to a fully balanced lift without distorting the module. However the spreader bar is quite expensive and usually leads to a requirement for a higher hook elevation.

The use of a spreader frame should only be considered in exceptional cases and does not prevent module distortion. The padeye/shackle option is limited by the safe working load (maximum 10MN) of the biggest shackle. The trunnion can accommodate higher loads.

Hook up is the completion of all joints and connections after installation.

For economic reasons, the overall construction strategy should keep hook up work to a minimum. Critical hook up work is the work required immediately to secure the object in order to survive the next storm.

Commissioning is not relevant to the structural design.

These activities are a major source of operational expenditure, OPEX, as introduced in Lecture 15A.1.

Some requirements are:

Removal requirements are different from country to country. In some depths of water full removal is required in some countries from the mudline upward. Elsewhere only the structure 75 m or more above the mudline must be removed.

Extensive engineering of removal is required to achieve a safe and effective operation. In the Gulf of Mexico removed structures are dumped in the form of reefs. It is very difficult and inefficient at present to include conceptual removal engineering in the design phase. When re-use of the facility is planned, then removal engineering should be developed early in the design.

i. fabrication

ii. weighing

iii. load out

iv. sea transport

v. offshore installation especially deckmating

vi. module installation

vii. hook-up

viii. commissioning

[1] API-RP2A: Recommended practice for planning, designing and constructing fixed platforms.

American Petroleum Institute, 18th ed., 1989.

The structural offshore code, governs the majority of platforms.

[2] AISC: Allowable stress design manual (ASD).

9th ed., American Institute of Steel Construction, 1989.

Widely used structural code for topsides.

[3] API-Bulletin 2V: Bulletin on design of flat plate structures.

American Petroleum Institute, 1st ed., 1987.

Valuable specialist addendum to API-RP2A.

[4] API-Bulletin 2U: Bulletin on stability design of cylindrical shells.

American Petroleum Institute, 1st ed., 1987.

Valuable specialist addendum to API-RP2A.

[5] D.v.d. Zee & A.G.J. Berkelder: Placid K12BP biggest Dutch production platform.

IRO Journal, nr. 38, 1987, pp 3-9.

Presents a recent example for a portal framed topside.

[6] R. Narayanan: Plated structures/Stability and Strength.

Applied Science Publishers, London, 1983.

Good designers guide to plated structures design.

[7] ANON: Gullfaks C platform deckmating.

Ocean Industry, April 1989, pp 24.

Good description of the actual mating of deck to GBS.

[8] A.G.J. Berkelder: Seafastening 105 MN Brent C deck.

Bouwen met Staal, nr.24 1979.

Presentation of seafastening design for GBS topside.