ESDEP WG 4A

PROTECTION: CORROSION

To expand Lecture 4A.2, providing young architects and engineers with guidance on using the information on the protection of steelwork in buildings.

Lecture 4A.1: General Corrosion

Lecture 4A.2: Factors Governing Protection of Steelwork

Lecture 4A.4: Corrosion Protection of Bridges

This lecture discusses the practicalities of design and how to deal with connections (fasteners) and welds. It covers the effects of the environment on the external steelwork of buildings and suggests protective treatments. Common internal environments are discussed. Hidden steel and steelwork in perimeter walls are dealt with separately.

The lecture ends with "special cases", i.e. steel in concrete, hollow sections and, cladding.

General considerations, the benefits of designing to allow the effective use of protective coatings and, making a conscious decision as to where they should be applied are dealt with in Section 2 of Lecture 4A.2. The requirements of Eurocode 3 [1] are described in Appendix 1.

Corrosion prevention truly starts on the drawing board. Design details which avoid water traps, ensure adequate drainage and promote air circulation restrict corrosion. Avoiding contact between dissimilar metals, removing sharp edges and corners are all important. Supremely important, but frequently overlooked or ignored in design is access for inspection, cleaning and maintenance. If the surface cannot be reached, it cannot be maintained.

Design must take into account the life required of the building, the likely time to first maintenance and, the intervals between each subsequent maintenance. The questions to ask when attempting to assess the life requirement of a building are given in Section 1.3 of Lecture 4A.2. Table 2 of Lecture 4A.2 shows typical protective systems related to simple definitions of environment. Paint types are described in Appendix 2 of Lecture 4A.2.

Connections (fasteners) are an integral part of every structure. Frequently they appear to be forgotten when the corrosion protection for the steelwork is decided upon. For example, in an aggressive environment several hundred microns of paint on beams will not effectively protect the structure if it is connected together by black bolts.

Bolts, nuts and other parts of connections need to be protected by a coating system of a standard at least equal to that provided for the general surfaces.

The risk of damaging precoated connections and the surfaces of connections during erection and assembly can be high. It may be necessary to specify a different coating system to that used on the steelwork to reduce the danger. Alternatively the coating of accessible connection surfaces can be delayed until after the steel is erected. The protecting of fasteners and the areas immediately around them is more difficult.

Where high performance paint systems are specified, stainless steel, weathering steel or hot dip spin galvanized fasteners should be considered.

Appendix 2 describes the treatment of faying surfaces of friction grip joints, black bolts bolted connections other than friction grip bolts, and deals with the means of ensuring satisfactory performance from connections and fasteners. The corrosion of fasteners is always a major potential hazard which can be overcome only by specifying fasteners suitable for the work in hand.

The welding technique influences whether weld areas are protected (a) after surface preparation and before welding or, (b) left bare until the welding is complete:

a) When blast cleaning takes place before fabrication a blast primer (see Appendix 2, Lecture 4A.2) can be used to protect steelwork. It is important to make sure this primer is compatible with the paint system which has been chosen to give long-term protection.

b) If blasting is after fabrication a "holding" primer of one of three types as noted in Appendix 2 of Lecture 4A.2 can be used to protect the surface until the paint system is applied. Care is needed to choose a primer which is designed for use after fabrication. Alternatively, the first coat of the chosen paint system can sometimes be substituted for the "holding" primer.

Welding zinc or aluminium coated steel is unsatisfactory when the non-ferrous coating is more than 25 mm thick. It is better to mask off the areas which will form the welds before applying the metal coating.

After welding, surface preparation of the standard specified for preparing the steelwork overall is required before applying the protective coating process. Some forms of welding leave alkaline deposits behind. These deposits must be removed by blast-cleaning followed by washing with clean water before applying protective coatings. This requirement does not apply to galvanizing where the process removes the deposits.

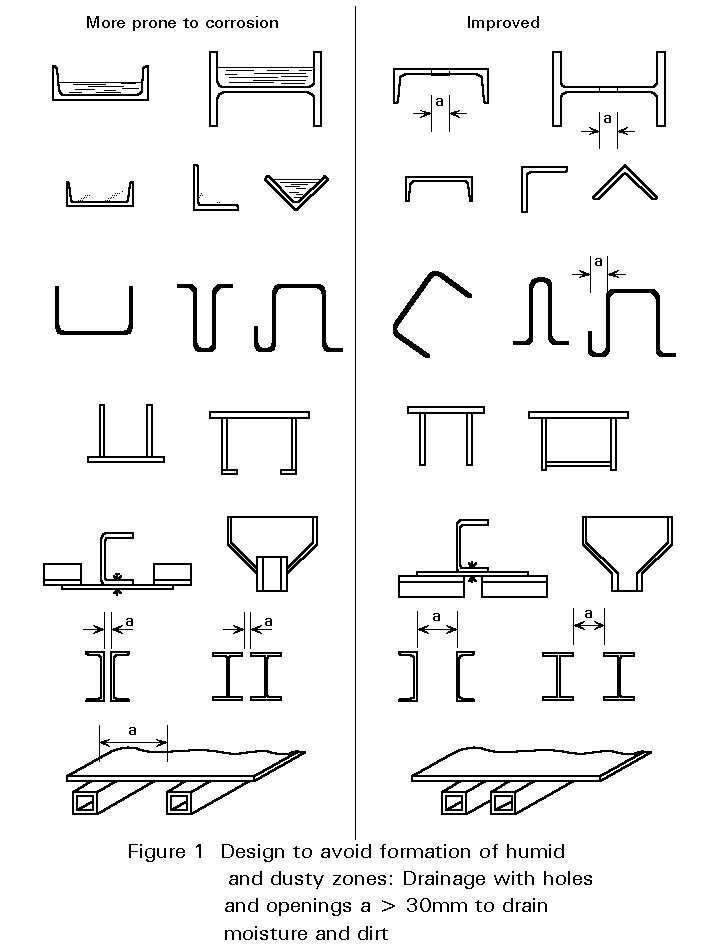

It is not possible to define the micro-climate surrounding a building. The rate of corrosion of structural steel greatly depends upon how long the steel remains wet. If the design allows for maximum rain water and condensation shedding then local corrosion is minimised. If details which collect rainwater or condensation cannot be redesigned, then adequate drainage must be allowed. (See Appendix 2 and Figure 1).

A classification of general exterior environments is set out in Table 1, Lecture 4A.2. Although it may appear subjective and unscientific, this very imprecise information is often the only data available as a basis for considering needs for corrosion protection.

Design plays a major part in establishing the environment to which the steel is subjected. Surfaces upon which water can hang or lay must be avoided as far as possible, so also must water traps. A particular problem with internal surfaces, e.g. in factories, is alternate wet and dry cycles when mildly acidic or alkaline water leaves behind salts which gradually build in strength to produce remarkably aggressive microclimates.

The generic paint processes in Table 2 of Lecture 4A.2 reflects the problems inherent to each environment. Thus all the processes in Environment C (Table 1 of Lecture 4A.2) are chosen for their water resistance rather than ease of application or tolerance to poor surface preparation.

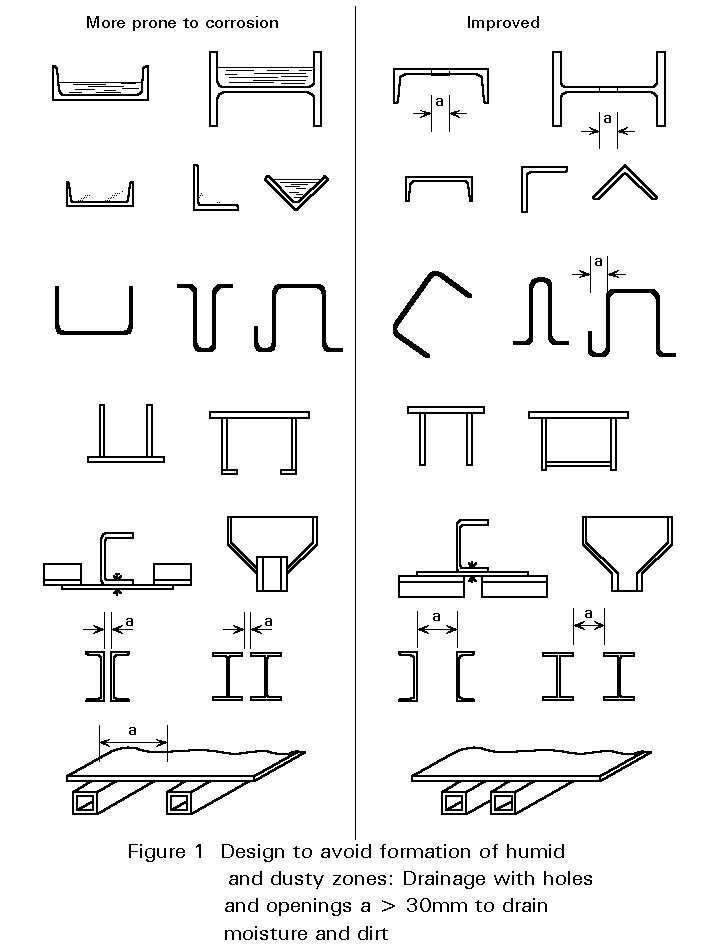

It is widely accepted that hidden steel, see Figure 2, in a dry heated interior, e.g. hollow encased sections or steelwork above a suspended ceiling, lasts for some 50 years without any protection. Corrosion is minimal in these circumstances and has no influence on the structural stability of a building. A proviso is that the steelwork is not exposed for longer than two years before it is clad. There is a more important consideration; will the interior remain dry? If the steel may possibly cool to fall below the temperature of the dew point then it will at times be wet. The protective treatment should be specified accordingly. System P5 provides adequate protection. More practical is to specify galvanizing system G1 or, a paint process tailored to the situation and not covered in Table 2 of Lecture 4A.2, i.e. an isocyanate cured pitch epoxy applied at the fabricator's shop or steel mill to a dry film thickness of 400-500 mm. Spark testing to detect thin areas or breaks in the film is essential with this type of protective system.

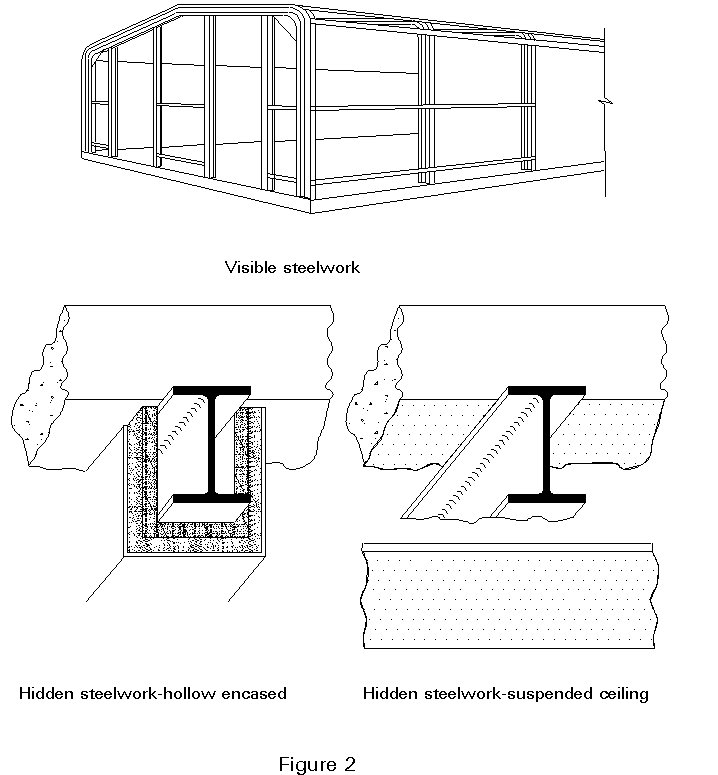

Steelwork in perimeter walls is another type of hidden steelwork, see Figure 3. It may be separate from the outer leaf, in contact with the latter or, embedded in the outer leaf. The protection problem arises essentially from driving rain rapidly saturating the outer skin, particularly through mortar joints, and wetting the exposed steelwork. The water flow is influenced by the absorbency of the outer skin; bricks of low porosity increase the water flow through the joint while a highly porous outer skin may effectively prevent migration of water in a cavity wall. The design should ensure adequate drainage away from the steelwork at the base of the wall.

A clear separation of steelwork from the outer leaf by non-absorbent insulating material at least 25 mm thick or, an air gap of at least 40 mm ensures the greatest durability. Design should avoid ties between the steelwork and the outer skin to prevent moisture bridging, i.e. heat conduction between the outer leaf and the steelwork. Protective coating systems for this situation are not covered in Table 2 of Lecture 4A.2. The most effective systems are 400-500 mm DFT (dry film thickness) of isocyanate cured epoxy pitch or, hot dip galvanizing - 85 mm for the steelwork and fixings.

Steelwork in contact with the outer leaf is best avoided. If contact is likely, then either of the two prospective systems noted in the paragraph above is appropriate.

Where steelwork is embedded in the outer leaf good drainage is essential to assist evaporation of moisture and to prevent pooling. It is wise to assume the cavity is not well ventilated and to protect the steelwork by galvanizing (85mm) or use of the pitch epoxy (400-500 mm) as noted above.

It should be noted that corrosion products expand and can damage the building fabric, e.g. by dislodging facing bricks. This is a similar problem to the spalling of concrete arising from corrosion of embedded steel reinforcement.

For many years it was held that steel in concrete required no protection. Provided that the compaction of the concrete was adequate, it was uncontaminated with salt, and remained crack-free, this view was true due to the high pH value of concrete. However the concrete thickness needs to be above 40 mm for protection to remain effective for the life of most structures.

A particular problem is the spalling or cracking of concrete associated with the corrosion of reinforcing bars (rebars) in concrete. External chlorides from de-icing salts, marine environments or internal sources, e.g. from saline aggregate, can alter the electrochemical environment locally causing the reinforcing steel in reinforced concrete structures to become non-passive.

If corrosion is remotely possible, then protection of the steel by fusion bonded epoxy coatings should be considered.

Rarely is protection of the inner surface of structural hollow sections necessary. If the section is sealed, no corrosion occurs. Where sections are incompletely sealed and there is no free flow of air, then no more than a light surface oxidation takes place. It is sensible to provide drain holes at the low points to prevent water being trapped, freezing and splitting the hollow section. Drain holes must be kept unblocked.

Completely open sections, e.g. box girders, may require internal protection. Galvanizing, fusion bonded epoxy coatings or chemical resistant paints are all possible solutions.

Prefinished cladding for roofing and walls is lightweight and its use allows cost savings to be made in the overall building frame. A variety of profiles is available with the basic material being either steel or aluminium. If steel, it is hot dip zinc or zinc/aluminium coated for protection against corrosion.

The basic metal is supplied in a coil or strip which is unwound, coated, cured and re-wound before being formed into a variety of different profiles. The coating systems are extremely sophisticated and outside the scope of this lecture.

When preparing a specification reference to a manufacturer's literature is unlikely to prove sufficient. The specifier needs to provide a "performance specification" covering key items, e.g. loading (including wind), substrate type, coating type (external and internal face), design life, environmental conditions and evidence of the suitability of the proposed protective system.

In the relation to resistance to corrosion and weathering, the following items are important when making the selection.

Galvanized steel cladding is strong but may corrode.

Aluminium requires taping at all joints with the steel structure; it is less resistant to site damage but less likely to corrode. Its use in hot climates needs careful consideration.

On aluminium, the coating is generally 30 mm or below. This coating does not give a good performance externally.

On galvanized steel cladding both 'thin' and 'thick' coating systems are available. As noted above, 'thin' coatings of 30 mm or below behave poorly outside. 'Thick' coatings (200 mm) are mainly plastisols. 'Thin' coatings are commonly PVF2, Acrylic or Polyester.

One must be cautious of manufacturers' descriptions. Many thin coatings are claimed to have excellent colour retention; no reference is made to the ease of site damage during storage, installation or, life of the building.

"Plastiscol" is a generic term applied to formulae whose performances vary dramatically. Be specific regarding performance pollution. Assess internal environments equally carefully.

The period to first maintenance is generally defined as the time after which the protective system no longer protects the surface. It can also be the point in time when the cladding's appearance becomes aesthetically unacceptable. It is important to specify which definition is being used.

When appearance is important, it should be noted that the same product weathers differently on north- and south-facing elevations or roofs. Data from manufacturers requires careful study.

Modern coated cladding may well have a life to first maintenance of twenty five years. Eventually however the coating will need refurbishing.

Deterioration of coatings has four phases:

Overpainting prepainted cladding is a major undertaking. The cladding may have been finished in one of seven generic types, all of which pose different problems. It is essential to involve a specialist contractor to apply the maintenance system. The system in turn must be supplied by one of a small number of European paint manufacturers producing paints specifically designed to maintain cladding.

[1] Eurocode 3: "Design of Steel Structures": ENV1993-1-1: Part 1.1: General rules and rules for buildings. CEN, 1992.

[2] pr EN 1029: Specification for hot dip galvanised coatings on iron and steel articles.

[3] BS 4221: Specification for sheradised coatings in iron and steel articles.

[4] BS 3382: Specification for electroplated coatings on threaded components.

[5] ISO 3269: Fasteners - Acceptance Inspection.

APPENDIX 1

Eurocode 3 Requirements

Eurocode 3 "Design of Steel Structures - Part 1 General Rules and Rules for Buildings" [1] sets out certain general requirements with regard to durability as follows:

the use of the structure

the required performance criteria

the expected environmental conditions

the composition, properties and performance of the materials

the shape of members and the structural detailing

the quality of workmanship and level of control

the particular protective measures

the likely maintenance during the intended life.

In order to meet these requirements the designer must consider all the risks which may arise and make the necessary provisions for an adequate protective treatment, with due regard to economy. The easy option of over-designing to cover highly unlikely risks must be avoided so that the client does not bear any unnecessary costs.

APPENDIX 2

A.2.1 Faying Surfaces of Friction Grip Joints

These surfaces are those which, when in contact with one another, transmit a load across the interface by friction.

Faying surfaces require special attention. If left bare all moisture access points must be effectively sealed. The alternative is to protect the faying surfaces, but the effect of the protective treatments on the slip-factor should first be closely investigated: their behaviour under static, dynamic and sustained loading should be considered.

Faying surfaces are usually blast-cleaned at the same time as the general surfaces of the steelwork. It may be advantageous to specify masking and that the masking should be retained as a temporary protection, being removed before assembly. The type of masking should be specified to ensure minimum contamination by adhesives. The method of preparing surfaces after stripping the masking should also be specified.

Where paint over sprayed metal is the specified protective system, masking may be used to prevent paint being applied to the faying surfaces of connections. If galvanizing is the protection, roughening can take place immediately before assembly. When galvanizing is to be overpainted, the roughening should be carried out before the masking is applied.

Edge sealing of the faying surfaces can be specified to prevent corrosion where steelwork is located in aggressive environments. The specification clauses should ensure that the edges on both faying surfaces are painted for a distance of 15mm inside the perimeter of the connection.

In similar environments, where load-indicating washers or bolts with load-indicating heads requiring feeler gauges for measuring shank tension are used, it is advantageous to specify that crevices should be sealed by applying high-build paint or mastic compatible with the coating system. This sealing should be carried out after the final tightening of all bolts (see Sections 1.2. and 1.3).

High-strength friction grip bolts are normally supplied with a light coating of oil. This coating is removed by weathering and/or swabbing with solvents. The exposed areas can be treated with the same protective system as the steel structure or, one modified to suit site conditions.

A.2.2 Fasteners

Where steelwork is to be manually cleaned after weathering, the fasteners may be prepared and treated in the same manner as the general surfaces. The specified primer must be suitable for site application to manually prepared steelwork.

Where the overall surface preparation is by blasting after bolting-up, the exposed surfaces of the bolts, nuts and washers should be blast-cleaned at the same time as the general surfaces. Such blast cleaning should also be used if high-strength friction-grip bolts are used in similar circumstances.

If surfaces are blast-cleaned prior to bolting-up and it is impractical to utilize the same preparation method for the connector surfaces, then pickling of the bolts may be specified to remove scale and assist in manual preparation of the exposed surfaces for coating. Pickling may not be suitable for high-strength friction-grip bolts. On site, after erection, fasteners must be treated with a corrosion inhibiting primer suitable for application to manually prepared steelwork under site conditions.

A.2.3 Metal Coated Fasteners

Fasteners may be hot dip galvanized, sheradized, zinc, cadmium plated or mechanically coated. The life of the coating for each metal is directly proportional to its thickness. Extra clearance is required on the thread to accommodate the thicker coatings and early ordering is advisable therefore. The thinner coatings should not be used without additional protection. European, ISO or National Standards should be specified to avoid substitution.

If they are to be overpainted, metal coated bolts should not be chromate.

a. Hot dip galvanizing

Fasteners are spin-galvanized to pr EN 1029; this process gives a minimum local coating thickness of 43 mm. This zinc is alloyed to the base steel. General grade high-strength friction-grip bolts can be galvanized but the threads should be lubricated to prevent galling.

b. Sheradizing

Sheradizing coatings are specified in BS 4921 [3]. The coating is alloyed to the base steel. A Class I coating has a minimum local thickness of 30mm and Class II coating 15 mm.

c. Electroplating

Thin coating of cadmium and zinc are specified in Parts 1 and 2 of BS 3382 [4], with a thickness of 7.5 mm for bolts more than 12 mm in diameter. Coatings with a minimum local thickness of 25 mm are covered by Part 7 of BS3382.

Cadmium plated components should be identified. On no account must they be flame-cut or welded because of toxic fumes which can be lethal.

A.2.4 Bolted Connections other than Friction Grip Bolts

Where the surfaces of fabricated components are prepared and coated before erection, the surfaces of the joints are usually coated at the same time.

When bare steelwork is erected prior to preparation and painting, the joint surfaces should receive one coat of the priming paint specified and two where the environment is other than benign. This treatment should be specified also for steelwork delivered to site treated with a blast primer only.

A.2.5 Ensuring Satisfactory Performance from Fasteners

Fixing nuts and bolts can be:

Hot dip galvanized

Sheradized

Electroplated

Mechanically plated

An adequate thickness of zinc must be specified and reference made to the relevant Standard document where one exists.

If the thickness of zinc is (a) too thin to offer protection for the design life of the structure or, (b) the zinc will require maintenance by painting then further protective coating must be specified for the surfaces exposed after assembly.

Where the zinc coating is the first part of the initial protective coating system, the total process should be applied to the fasteners as part of the overall painting.

If the zinc is the sole protection, then the thickness on the fastener can be built-up by applying.

i. Zinc-metal containing paint.

ii. A protective paint system, the first coat formulated for direct application to zinc.

Paint manufacturers advice should be sought for a system giving protection equivalent to that given to the main structure.

Notwithstanding the environment, when electroplating is specified strict quality assurance and authoritative inspection is required to ensure both adequate adhesion and the correct coating thickness are achieved. If they are not, this coating type can be considered 'sacrificial' in the same way as a paint blast primer or holding primer.

Methods of acceptance inspection for fasteners are found in ISO3269 [5].