ESDEP WG 4A

PROTECTION: CORROSION

To expand upon Lecture 4A.1, giving the practical means of protecting steelwork at a level suitable for young architects and engineers.

None.

Lecture 4A.1: General Corrosion

This lecture covers the assessment of the required life design for the successful use of protective systems and surface preparation. The coatings commonly used to protect steel are described and the use of stainless and weathering steels are briefly discussed. Finally a general discussion of maintenance is given.

Table 1 classifies the principal types of environment that have a significant influence on the life expectancy of steel.

In dry, heated buildings, e.g. offices, hospitals, warehouses, the corrosion rates of carbon steel are usually very low. Steel can be used without protection in such environments when it is hidden. Elsewhere it is coated for aesthetic or hygienic reasons.

Many interiors are not dry however and steelwork requires protection in these situations, as well as in exterior environments.

Structures and plant usually have a "design life". If after execution of the structure access is impossible, the initial protective system needs to have the same life as the steel. Economic pressures often increase the functional life of plant significantly beyond the "design life". Changes in expectation usually occur after the initial protective system is in place. It is sensible therefore to consider this possibility at the start of every new project.

Table 2 gives in column (a) typical lives in the general environment quoted to prevent deterioration of the steel using various coating systems. Column (b) gives the likely time to first refurbishment where good appearance and the maintenance of a readily cleaned surface are important. Neither set of figures can allow for the influence of local conditions, e.g. heavy overnight condensation due to the unplanned shutting down of ventilating systems to save money.

Protective systems require regular inspection allowing unexpected local failures to be repaired. Ideally the base steel should never be exposed. If the first coat of the system is zinc galvanising or metal spray then it should be considered part of the structure, the paint coats being refurbished at intervals which ensure it remains unexposed.

When there is data on the performance of a protective system on similar structures or plant, prediction of the intervals to maintain the top coat(s) is fairly easy. Since the initial failure of a protective system may be sooner than anticipated, the estimation of the interval for some breakdown to bare steel can be complicated.

It may be necessary to assess each part of a structure separately. For each assessment the following points should be taken into account:

a. Required life of structure/plant.

b. Decorative and hygienic requirements. The decorative life of a coating (and its ability to be readily cleaned) is rarely as long as the protective life of the system, see Table 2.

c. Irreversible deterioration if scheduled maintenance is delayed.

d. Difficulty of access for maintenance.

e. Technical and engineering problems in maintenance.

f. Minimum acceptable period between maintenance.

g. Total maintenance costs, including plant shut-down, closure of roads, access, etc.

The design of structures and plant is based largely on data and functional requirements which can be quantified, e.g. 'the steelwork supports plant manufacturing a specific product and has a life expectancy of 25 years'. The selection of a protective system involves many factors; these factors vary widely according to the type of structure, its complexity, its function, the general environment, (see Table 1) the influence of microclimates and the effects of possible environmental changes (natural and otherwise) which may occur during the required life.

Other factors affecting selection are quantitative, e.g. time to first maintenance, planned maintenance schedule to cover the required life of the structure or plant, thickness of coatings, etc. They should be viewed with caution because the degree of variation may differ between one coating system and another.

Quotations may vary considerably for the same system irrespective of whether it is hot dip galvanising, metal spray or paint. Great care is necessary to ensure quotations for apparently identical products or services do cover the same materials, application with the same degree of control, and comparable quality of finish in terms of both required durability and appearance.

Some of the critical conditions and circumstances that have to be taken into account before selecting a protective system are listed in question form in Appendix 1. Not every question is relevant to a particular job and the importance of the relevant questions varies. The order of relevant questions might be modified in the light of answers to later questions. The list should be studied as a whole before the questions are considered in detail.

The design of structures and plant can influence the choice of protective system. It may be appropriate and economic to modify the design to suit the preferred protective system. The following points should be noted:

a. Provide safe and easy access to and around the structure to facilitate maintenance.

b. Design the elements:

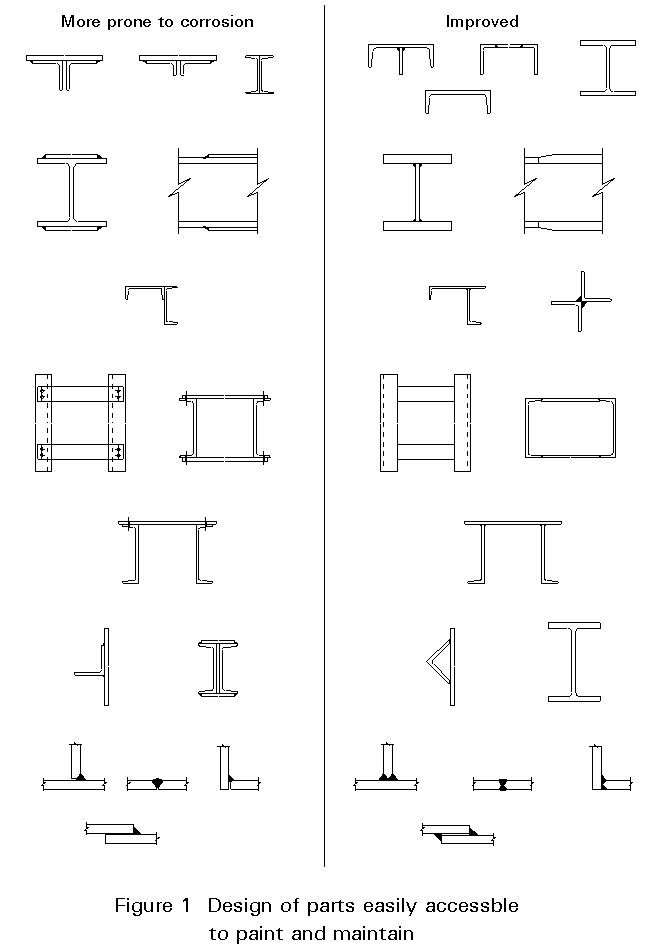

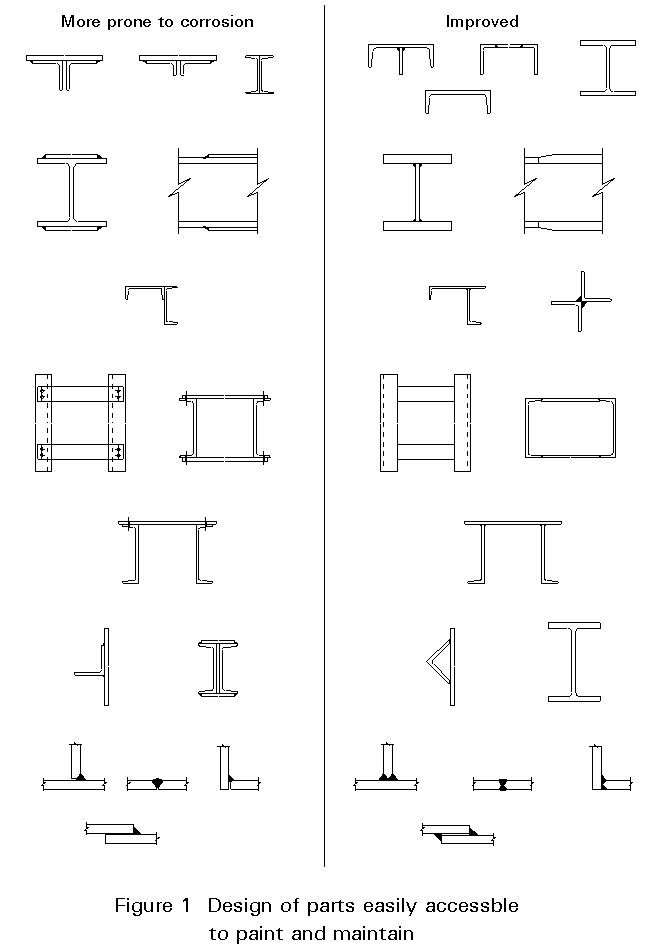

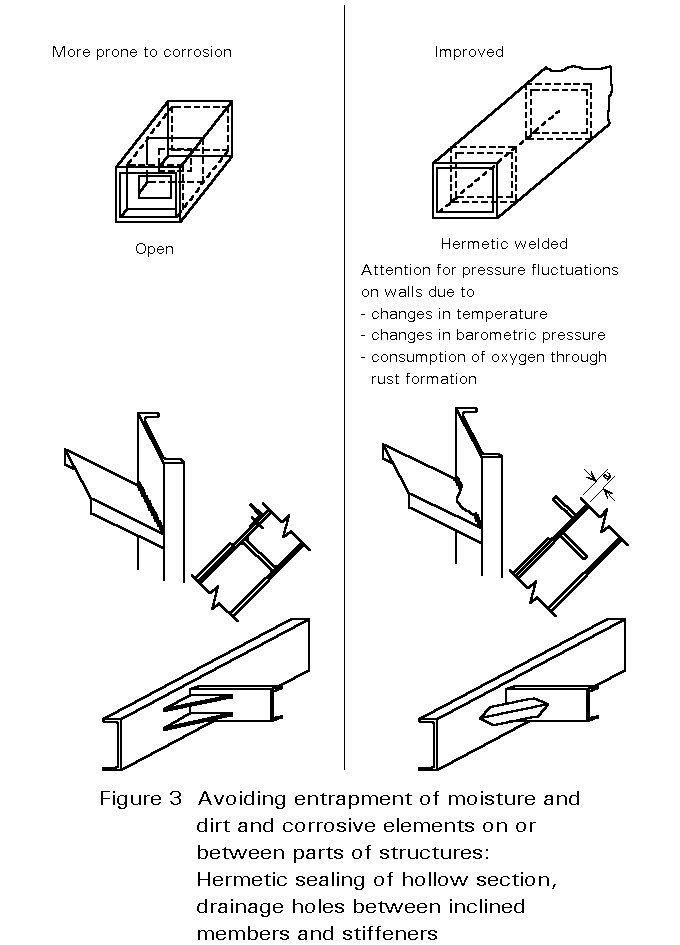

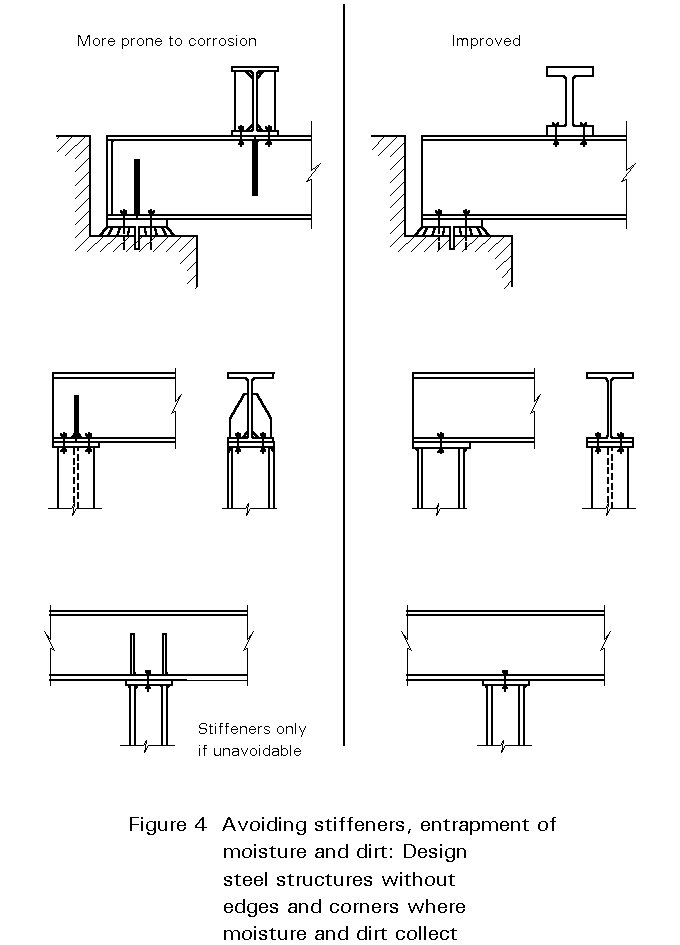

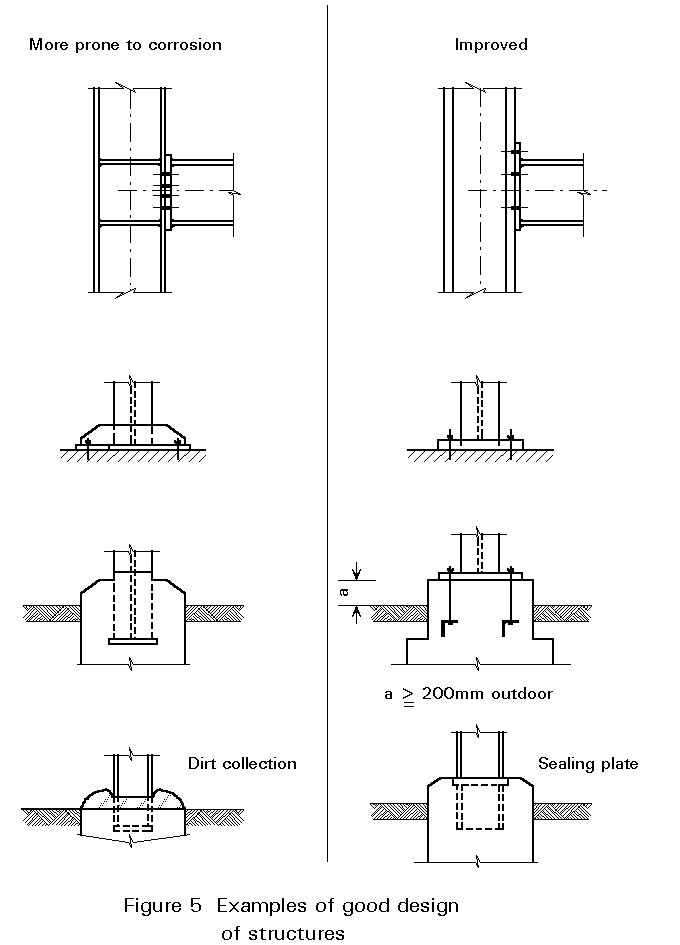

i. to avoid pockets and recesses in which water and dirt can collect, see Figures 1 - 5.

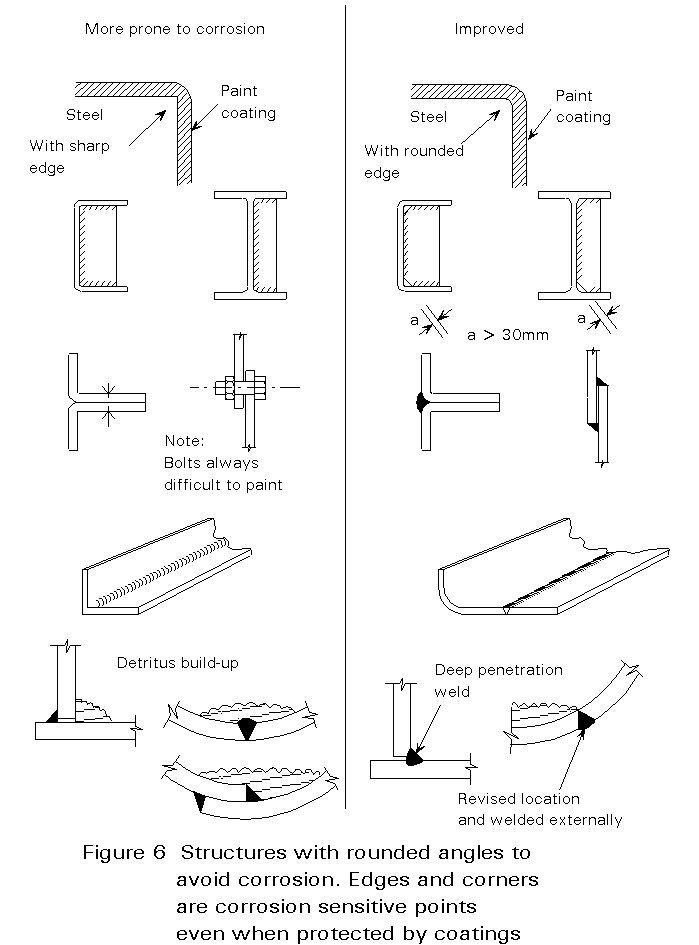

ii. to eliminate sharp edges and corners, see Figure 6.

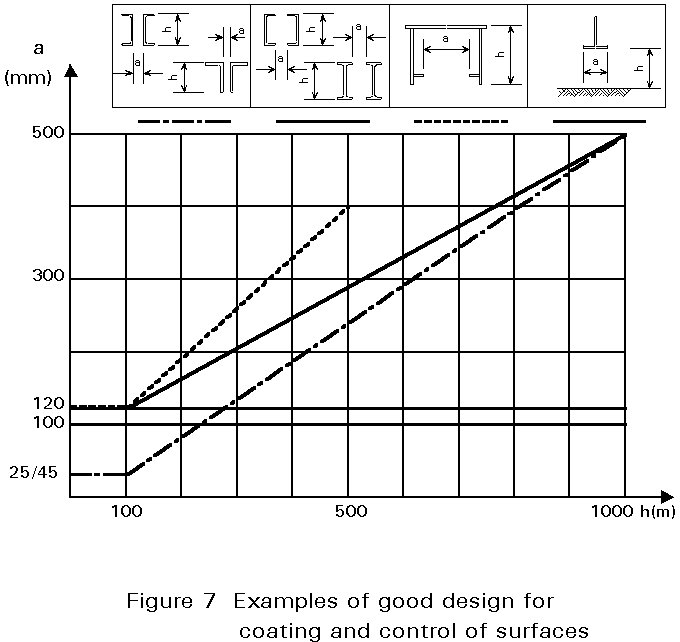

iii. to provide clear access for painting e.g. to allow space to use a paint brush or spray gun, see Figure 7.

c. Any areas which are inaccessible after erection require a coating system designed to last the required life of the structure. Is this feasible or should the design be modified?

d. Certain structural sections are more suited to some coating systems than others, e.g. hollow section are more easily wrapped than structural shapes.

e. The method or size of fabrication may preclude or limit some protective systems, e.g. friction grip bolts, galvanising.

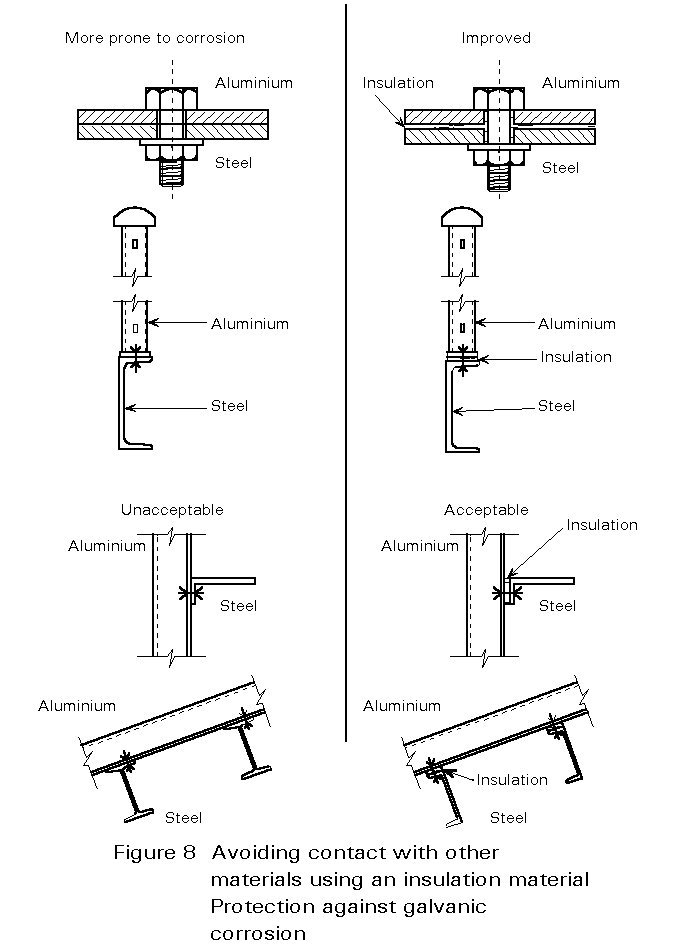

f. If bimetallic corrosion is possible, additional protective measures are necessary, see Figure 8.

g. Where steel is likely to be in contact with other building materials, special precautions may be necessary e.g. oak timbers.

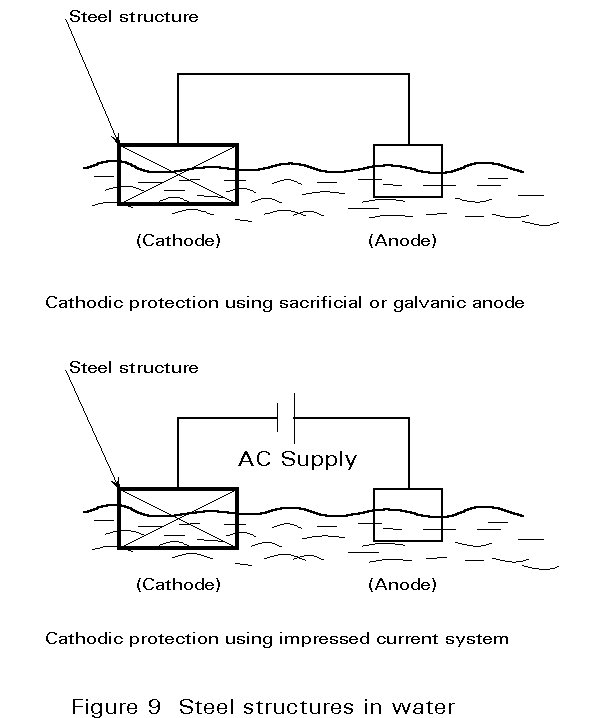

h. For steel structures in water, cathodic protection may be the best solution, see Figure 9.

In this case "where" means should the protective coating system be applied on or off site.

Protective system are more durable when applied in the fabrication shop or steel mill. Where there is a likelihood of substantial damage occurring during transportation and erection specifiers may prefer the final one or two coats of protection to be applied on site. Paints specified for site use must be tolerant of delay and a measure of intercoat contamination. The specification should state clearly who is responsible for quality control at each stage of fabrication and processing.

Where the total system is applied off-site, the specification must cover the need for care at all later stages to prevent damage to the finished steel and set out repair procedures for the coatings once the steelwork is erected.

The protective treatment of bolts, nuts and other parts of the structural connections require careful consideration. Ideally their protective treatment should be of a standard at least equal to that specified for the general surfaces.

Where high performance paint systems are to be used, it is worth considering hot dip spun galvanised or stainless steel fasteners.

The mating surfaces of connections made with high strength friction grip bolts require special treatment, see Appendix 2 in Lecture 4A.3.

The surface preparation of the steelwork has a major influence in determining the protective value of the coating system.

For galvanising and metal spraying, surface preparation is an integral part of the process and is included in national standards for these operations. With paint systems there is usually a choice of preparatory methods. Therefore the actual method chosen for a specific job must be specified as part of the protective coating treatment.

The choice between blast-cleaning and manual cleaning is partly determined by the nature of the coatings to be applied. Coatings applied to a degreased blast-cleaned surface always last longer than similar coatings applied to manually cleaned surfaces. However, some short-life coatings do not warrant the high cost of blast-cleaning as required for long-life coatings. Details of methods for blast cleaning surfaces are given in ISO 8504 [5].

Grease and dirt are best removed by proprietary emulsion cleaners followed by a thorough rinsing with water, by steam-cleaning, or by controlled high pressure water jets.

Where it is necessary to use white spirit or similar solvents to remove oil or grease, the use of detergent or emulsion cleaner should follow before completing the operation by thorough rinsing with clean fresh water.

Degreasing by washing with solvent is not recommended because it can lead to the spreading of a thin film of oil or grease over the surface.

Mill-scale is made up of the surface oxides produced during the hot-rolling of steel. It is unstable. On weathering, water penetrates fissures in the scale and rusting of the steel surface occurs. The mill-scale loses adhesion and begins to shed. It is an unsatisfactory base and needs to be removed before protective coatings are applied.

In general, rusted steel surfaces are not a satisfactory base for the application of protective coatings, although some primers have a limited tolerance to residual rust left on steel surfaces after manual cleaning. The means of removing rust and scale are described below.

Abrasive particles are directed at high velocity against the metal surface. They may be carried by compressed air or high-pressure water, or thrown by centrifugal force from an impeller wheel. For some open blasting, high pressure water without abrasives may be used. The various methods are listed in Table 3.

Commonly used abrasives for cleaning steelwork are listed in Table 4 with notes on their advantages and disadvantages.

The choice of blast-cleaning method is determined by the following factors.

a. Shape and size of steelwork

Centrifugal methods are economic for plates and simple sections; they can also be used for large prefabricated sections, e.g. bridge sections, but only in specially designed plants. 'Misses' discovered by inspection can be cleaned with open-blast techniques. For large throughput of shaped items, e.g. pipes, both open and vacuum blasting techniques can be used in continuous and automatic plants.

b. Effect of the stage at which cleaning is carried out

For blast-cleaning on site, open or vacuum-blasting methods have to be used as on large fabricated sections. It is usually impractical to use centrifugal methods.

c. Throughput

Centrifugal plants are economic for a high throughput, but even with a low throughput the method may still be preferable to large-scale open cleaning.

d. Environmental conditions

Despite its relatively high cost, vacuum blasting may be necessary to avoid contamination of the immediate area with abrasive. It should be ensured that the blast-cleaning process does not affect adjacent materials.

e. Types of surface deposit to be removed

Wet-blasting methods, with abrasives, are particularly suitable for removing entrapped salts in rust and for abrading old, hard painted surfaces, e.g. two-pack epoxies, before recoating.

On new work, blast cleaning can be carried out before or after fabrication. When it is before fabrication a "blast" or "holding" primer is applied to prevent corrosion during fabrication. Areas damaged during fabrication, e.g. by welding, require re-preparing and priming as soon as possible.

ISO 8501-1 1988 is a visual standard which shows different degrees of blast cleaning on steel of four levels of rusting [1]. The reference prints are in colour and the standard is based on the widely used Swedish Standard SIS055900 [2]. It is used to specify and control the standard of abrasive blast cleaning required.

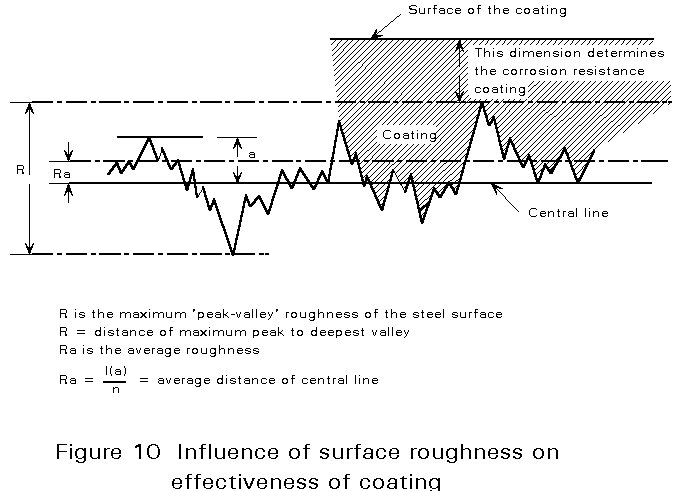

Because blasting roughens the surface, some control of the profile produced is important. If the distance between the highest peak and the deepest trough is too much then the peaks may not be protected adequately, Figure 10. ISO8503-1 1988 is a standard for surface comparators [3]. Visual comparison between the comparator, Figure 11, and blasted surface allow the latter to be graded "Fine", "Medium" or "Coarse" profile. The peak to valley distance for each grade is specified in the standard; shot and grit blasted profiles are different and there is one comparator for grit and one for shot blasting.

ISO8501-1 [1] is intended for use with previously unpainted steel. ISO8501-2 [1] is being prepared and relates to the treatment of previously painted steelwork.

In both the above standards the term Surface Cleanliness is used. This is slightly misleading because although it refers to how effectively mill scale and rust have been removed, it sometimes is assumed to include chemical cleanliness. This is not so. Tests for assessing the surface cleanliness are given in ISO 8502 [4]. ISO 8502-1 gives details of site tests for soluble iron corrosion products and ISO 8502-3 provides a method for the assessment of dust on the surface and these are the only standards of real use at present. ISO 8502-2 gives a method of determining in a laboratory the presence of chlorides and further part giving guidance on the estimation of condensation is in course of preparation.

Flame cut edges have to be smooth and corners ground in order to make a durable paint coating. A sharp corner creates a thin film and a starting point for corrosion.

Manual cleaning, possibly using power assisted tools, is the method most frequently used for practical or economic reasons, although it is the least effective. In due course Part 3 of ISO 8504 [5] will cover hand and power tool cleaning but at present the only relevant standard is ISO8501-1 [1] which contains two visual preparation grades for scraping and wire-brushing [2].

As indicated in Lecture 4A.1, the common methods of protecting steelwork are paints, galvanising, zinc or aluminium metal spray or "duplex" systems where one of the last three is over-coated with paint. The main characteristics of the three groups are given in Lecture 4A.1. Appendix 1.

Paints have three main components, a resinous components which literally glues them together and is best referred to as the "film former", pigment to give colour, weather resistance and in some cases corrosion inhibition and, solvents to produce the correct consistency for application, control of the drying rate, etc.

It is the film former which influences a paint's main properties, e.g. hardness, flexibility, water resistance. For convenience the paint types listed in Appendix 2 are divided into three families, drying oil based paints, one pack chemical resistant paints and 2-pack varieties. In each case the main film formers and pigments are indicated, together with typical end uses for each broad family.

Usually there are three components, 'primer', 'undercoat' and 'finish' in a paint system.

Primers. Their functions are to promote adhesion and protect from corrosion. Since film thickness is a very important in protection, two coats are frequently specified - sometimes three when the last two are applied by brush.

Occasionally specifiers refer to the second and third coat of primer as 'primer undercoat'. Frequently this misleads the contractor because the branded products freely available never feature this latter term in the product description. The specifier is advised to label the system 'First coat', 'Second coat', etc., following with the appropriate generic description.

Undercoats. On steel, traditional undercoats provide the right colour base for the finish; they adhere to the primer and little else. The high performance undercoat is more accurately described as an 'Intermediate coat'. It is a second barrier should the steel be bared by damage or erosion. Often coats used for this function can stand in their own right as finishes.

One important feature is to provide dry film thickness. A traditional undercoat gives about 25mm per coat; those used on steel in other than a being environment must give a minimum of 50mm, with heavier duty types producing 100mm plus.

Finishes. They supply the required colour, gloss or sheen level and resist weathering, abrasion, and chemical attack, as appropriate. More than one coat may be required depending on product type, exposure, environment, colour, etc. Dry film thicknesses per coat vary from 25mm for a simple oil based product to 100mm or more for two pack epoxy coatings.

a. Hot Dip Galvanising

The process deposits about 85mm on the surface of the structural steel. Thicker films can be obtained in some circumstances. Galvanising must not be confused with Sheradising which achieves no more than 30mm zinc thickness or electroplating which deposits even less thickness.

b. Strip Mill Galvanising

Strip mill galvanising utilises sophisticated plant to clean, pickle and plate strip with non-ferrous metals under carefully controlled conditions. The exterior surface of proprietary branded products, e.g. building cladding is likely to be finished with a 20-25mm protective layer of zinc or zinc/aluminium (the latter varying from 5 to 55%). This layer may be overcoated on the same production line with highly durable organic finishes of varying dry film thicknesses.

The usual methods of applying zinc and aluminium are gas combustion and electric arc. Very high standards of blasting and surface cleanliness are essential. Metal spraying and sealing are carried out by specialist contractors. Inspection must be undertaken by qualified metal spraying inspectors.

All grades of steel can be metal sprayed and there is no size limit. Work can be undertaken at works or on site. Aluminium is rarely applied at thicknesses greater than 150mm. In polluted or immersed conditions zinc is applied at 200-250mm.

Sprayed aluminium should be sealed. Zinc spray must be sealed if it is to be painted or during maintenance. Sealers are applied immediately after metal spraying and should not increase the thickness of the metal coating. There are many sealers and it is wise to ask the paint manufacturer for a specific recommendation for each job.

Both zinc and aluminium spray have good heat resistance, zinc up to 100°C and aluminium to 500°C.

Galvanising and paint. The selection of paints is more critical than for steel. Some paints have been developed for direct application to galvanised steel but results are variable. Acceptable pretreatments include etch primers, proprietary pretreatments which provide a 'key' for the paint, certain water borne primers formulated specifically for the purpose. The paint manufacturers advice should always be obtained.

Zinc or Aluminium Spray and Paint. Sealed spray can be overcoated without difficulty using a wide range of coatings. Unsealed zinc in particular is extremely difficult to paint; the formation of zinc corrosion salts ("white rust") can cause severe blistering.

The use of a mixed system. Non-ferrous metal plus paint systems, can produce a layer which will outlasts either component if used alone. However, if the environment is aggressive to zinc or aluminium, their use is questionable as opposed to seeking to protect them by overpainting, i.e. outside pH range of 5-12 for zinc or 4-9 for aluminium.

In order to assist the specifier of corrosion preventative coatings in selecting the materials to use and the workmanship and inspection requirements needed, two further standards are now in course of preparation.

The standard dealing with paint products has been allocated the number ISO12944 [6] and that dealing with metallic products is as yet unnumbered [7].

These are scheduled to become available by about 1996/7.

All protective coatings require maintenance and there are a number of ways in which the need becomes apparent.

In the extreme, the need for maintenance is shown when a mechanical or structural failure occurs as a complete surprise because the building or plant has never been the subject of regular inspections.

The need may also be manifest when visible coating failure or corrosion is noted by accident, e.g. when casually passing through a building.

The preferred method of determining maintenance needs is by means of planned inspections made at regular intervals. The comparison of the results of inspections with reliable records of the first and subsequent inspections give the basis for defining maintenance needs.

The aim of maintaining coatings is to preserve a structure or building so that it performs its required functions throughout its designed life safely, efficiently and economically. For this purpose a maintenance schedule for the structure or building is used to manage properly planned inspections and to keep reliable records.

Consideration of maintenance should start when a new project is being planned. The specifier should take into account the effects not only of the design upon maintenance painting, but also the influence of the initial coating system.

Drying Oil Based Paints The paints are readily overcoated with similar products if the surface is cleaned and if very hard, abraded. "Upgrading" to one or two-pack chemical resistant paints without completely removing the oil-based paint is unlikely to prove satisfactory.

One Pack Chemical Resistant Paints They can usually be safely overcoated with similar materials once the surface is cleaned. An exception is a moisture curing urethane system. Such systems may well require light blasting to obtain adhesion. Two pack products can be applied over moisture cured urethanes, but is unusual to use them over the more common one pack chemical resistant products, e.g. vinyl and chlorinated rubber resin based paint. Drying oil based paints are rarely applied over this particular class of paints and never in wet environments.

Two Pack Chemical Resistant Paints They are usually hard and are difficult to maintain unless lightly blasted. They are maintained by the application of similar products or, one pack chemical resistant materials, but never with drying oil based paints.

Galvanised Steelwork It can only be safely over-coated when all soluble corrosion products are removed. Once removal of these products is achieved, virtually any paints from the families noted above can be used. Etch primers are available which assist adhesion to the zinc surface.

Metal Sprayed Steelwork If metal sprayed steelwork has been exposed unsealed, it is virtually unpaintable. Sealed coatings give few problems.

The choice of a maintenance paint process depends on the existing coating and its condition, the standard of surface preparation possible, the working environment, time available, safety requirements, access and, economic considerations.

The decision of whether maintenance is to be by patch painting or a complete recoat is influenced as much by access as the state of the existing work. For example, if much scaffolding is required it may be more economical to repaint overall.

If there is more than 5% rusting of the substrate painting overall will certainly be economical. The "European scale of degree of rusting for anti-corrosive paints" presents monochrome pictures of nine degrees of rusting from Re1 (0,05%) to Re9 (95%).

In summary, successful maintenance starts at the beginning overall new project with the specifier projecting the consequences of his design and choice of initial paint system into future maintenance - can it be done and, with what? It continues with a strict, regular inspection routine, the results of which are accurately recorded and become part of a detailed maintenance schedule. It ends with maintenance painting specifications tailored to the job in hand and with the provision of adequate inspection to ensure the specification is followed.

ISO 8500 series Preparation of steel substrate before application of paints and related products.

[1] ISO 8501 Visual assessment of surface cleanliness

Part 1 Rust grades and preparation grades of uncoated steel substrates and of steel substrates after overall removal of previous coatings.

Part 2* Preparation grades of previously coated steel substrates after localized removal of previous coatings.

[2] SIS 05 5900: 1988, Preparation of steel substrate before application of paints and related products - Visual assessment of surface cleanliness.

[3] ISO 8502 Tests for the assessment of surface cleanliness.

Part 1 Field tests for soluble iron corrosion products.

Part 2 Laboratory determination of chloride clean surfaces.

Part 3 Assessment of dust on steel surfaces prepared for painting (pressure sensitive tape method).

Part 4* Guidance on the estimation of the probability of condensation prior to paint application.

[4] ISO 8503 Surface roughness characteristics of blast-cleaned substrate.

Part 1 Specifications and definitions of ISO surface profile comparators for the assessment of abrasive blast-cleaned surface.

Part 2 Methods of the grading of surface profile of abrasive blast-cleaned steel. Comparator procedures.

Part 3 Method for the calibration of ISO surface profile comparators and for the determination of surface profile - focusing microscope procedure.

Part 4 Method for the calibration of ISO surface profile comparators and for the determination of surface profile - Styles instrument procedures.

[5] ISO 8504 Surface preparation methods.

Part 1 General principles.

Part 2 Abrasion blast-cleaning.

Part 3 Hand and power tool cleaning.

[6] ISO 12944* Protective paint systems for steel structures

Part 1 General Introduction.

Part 2 Classification of Environments.

Part 3 Types of Surface and Surface Preparation.

Part 4 Classification and Definitions of Paint Systems and Related Products.

Part 5 Performance Testing.

Part 6 Workmanship.

Part 7 Design.

Part 8 Guidance for Developing Specification for New Work and Maintenance.

[7] Metal coatings for the corrosion protection of iron and steel in structures.

*

In course of preparationTable 1 Classification of Environments

|

INTERIOR ENVIRONMENTS |

|||

|

Environment category |

Environment |

Corrosion risk |

Examples |

|

A |

Normal (RH below 60%) |

Negligible |

Offices Shops Industrial Production/Assembly Warehousing Hospital Wards Schools Hotels |

|

B |

Occasional Condensation |

Low |

Unheated Buildings Vehicle Depots Sports Halls |

|

C |

Frequent Condensation |

Significant |

Food Processing Plants/Kitchens Laundries Breweries Dairies |

|

Not covered - seek expert assistant |

Chemical Processing Plant Dye Works Swimming Pools Paper Manufacture Boat Yards over Seawater Foundries/Smelter |

||

|

EXTERIOR ENVIRONMENTS |

|||

|

D |

Normal inland |

Low |

Industrial plant and supporting steelwork Bus/train terminals |

|

E |

Polluted inland |

Significant |

Tank farms, cranes, docks, power stations |

|

F |

Normal coastal |

High |

Docks, cranes, container installations, power stations refineries |

|

G |

Polluted coastal |

Very high |

Tank farms, industrial plants supporting steelwork |

|

Not covered - seek expert assistance |

Aggressive industrial environments such as steelwork adjacent to acid plants, salt storage depots, electroplating shops, chemical works etc. Buried or immersed steelwork Seawater splash zones. |

||

Table 2 Typical Protective Systems

Introduction

Whilst there are numerous protective systems available, only twelve have been selected for this lecture.

These are eight basic paint systems (P1 to P8) on which there can be variations of paint types (see Appendix 2); one galvanizing system (G1); and two metal spray systems (AS1 and 2).

Whilst the systems remain unaltered between environments, the notes vary to cover the changes that are necessary.

Table 2 Environments A & B: Typical Protective Systems |

|||||||

|

Interior dry and interior with occasional condensation |

Dry film thickness m m |

Cost comp |

Likely time to first maintenance in years |

Comments upon initial systems |

Repaint - likely system |

Comments upon repaint system |

|

|

(a) |

(b) |

||||||

|

prevent steel corrosion |

maintain appearance hygiene etc |

||||||

|

P1

Off site: Blast to Sa 2½, ISO 8501-1 Medium Profile ISO 8503 Part 1

Coat 1 Blast Primer Type 1, 11 or 111 Coat 2 or Oil Based Anticorrosive Primer

On site: Rectify transit/erection damage with Coat 2 Primer

Coat 3 Oil Based Undercoat Coat 4 Oil Based Finish

Total DFT Total DFT using micaceous Iron oxide pigmented undercoat

Total DFT using Micaceous Iron oxide pigmented undercoat and finish

|

15(1) 50

(50)

25 35

110 130

150 |

20+ 20+

20+ |

7 7-12

7-12 |

1. Ignore this DFT in calculating total thickness required for protection. 2. Accurate costing possible. 3. Controlled environment for preparation/priming.

4. Pre or post fabrication priming possible. If post fabrication, omit coat 1. 5. Total system can be applied on site see (4) above. Cost is likely to increase. Quality control is more difficult.

6. The use of micaceous iron oxide pigmented undercoat and finish give better edge protection. 7. Coats 3 & 4 can also be replaced with one coat of a high build finish. |

Prepare and spot prime - oil based anticorrosive Primer plus one or two coats oil based finish. |

Spot priming should be less than 1% Top-coats only refurbished overall so maintenance relatively straight-forward. |

|

Table 2 Environments A & B: Typical Protective Systems |

|||||||

|

Interior dry and interior with occasional condensation |

Dry film thickness m m |

Cost comp |

Likely time to first maintenance in years |

Comments upon initial systems |

Repaint - likely system |

Comments upon repaint system |

|

|

(a) |

(b) |

||||||

|

prevent steel corrosion |

maintain appearance hygiene etc |

||||||

|

P2 On site: Manual/Mechanical preparation to St 2, ISO 8501-1 Coat 1 Oil Based Anticorrosive Primer Coat 2 Oil Based Undercoat Coat 3 Oil Based Finish Total DFT

Total DFT using micaceous iron oxide pigmented undercoat

Total DFT using micaceous iron oxide pigmented undercoat and finish |

50 25 35 110

130

150 |

20+

20+

20+ |

5(1)

5+(1)

5-7(1) |

1. light millscale, rust in pits will not be removed. This may cause paint detachment before the top coats need refurbishing.

2. Coats 2 & 3 can be replaced with 1 coat of a high build finish.

3. The use of micaceous iron oxide pigmented undercoat and finish will give better edge protection. |

Prepare spot prime oil based Anticorrosive Primer bring forward with oil based under coat apply 1 or 2 coats of finish overall.

OR

1 coat high build finish. |

May require up to 25% priming & bringing forward failure due to millscale detachment unpredictable.

Planned maintenance budgeting difficult. |

|

|

P3 On site: Manual/Mechanical preparation to St 2, ISO 8501-1 Coat 1 Non oxidising 'grease' paint or propriety 'anticorrosive' compound

Coat 2 As coat 1 Total DFT |

100+

100+ 200+ |

20+

20+ |

not

app |

1. This process is for hollow encased steelwork. It is not decorative.

2. Check risks in the event of fire.

3. Some manufacturer's may recommend a 'penetrating' primer. |

Refurbish with original material or similar. |

Establish consequence of increasing the total film thickness in the event of fire. |

|

Table 2 Environments A & B: Typical Protective Systems |

|||||||

|

Interior dry and interior with occasional condensation |

Dry film thickness m m |

Cost comp |

Likely time to first maintenance in years |

Comments upon initial systems |

Repaint - likely system |

Comments upon repaint system |

|

|

(a) |

(b) |

||||||

|

prevent steel corrosion |

maintain appearance hygiene etc |

||||||

|

G1 On site: Galvanize - pr EN 1029 |

85 |

20 |

not applicable |

Size limitations. Not decorative. Not readily cleaned in service. *Life using galvanized fasteners. |

Oil based anticorrosive primer calcium plumate pigmented (lead) containing - T - Wash or 2-pack etch primer similar to Type 1 Blast primer 1 coat oil based undercoat 1 coat oil based finish. |

Corrosion products must be washed prior to painting lead - containing primers impose limitations. T Wash must be rinsed off thoroughly. |

|

|

AS1/ZS1

Off site: Zinc or aluminum spray to BS 2569 - sealed Aluminium, Unsealed zinc |

100 100 |

20+ 20+ |

not applicable |

No size limitations. Not decorative, retains dirt, oil etc., readily. Not readily cleaned in service. * assumes fasteners treated to same standard. |

Non lead containing oil based anticorrosive primer 1 coat oil based undercoat 1 coat oil based finish. |

Corrosion products must be removed before priming. |

|

Table 2 Environment C: Typical Protective Systems |

|||||||

|

Interior frequent condensation |

Dry film thickness m m |

Cost comp |

Likely time to first maintenance in years |

Comments upon initial systems |

Repaint - likely system |

Comments upon repaint system |

|

|

(a) |

(b) |

||||||

|

prevent steel corrosion |

maintain appearance hygiene etc |

||||||

|

P4 Off site: Blast to Sa 2½, ISO 8501-1 Medium Profile ISO 8503 Part 1

Coat 1 Blast Primer Type 11 or 111 Coat 2 One-pack Chemical Resistant Primer

On site: Rectify transit/erection damage with One-pack Chemical Resistant Primer.

Coat 3 One-pack Chemical Resistant Undercoat Coat 4 One-pack Chemical Resistant Finish

Coat 4 Replacing with fill gloss One-pack Chemical Resistant Finish gives 25 m m for final coat: Total DFT becomes

OR

Add Coat 5 - full gloss One-pack Chemical Resistant Finish giving additional 25 m m: Total DFT becomes |

15 75

(75) 75 75 225

175

250 |

15+

10+

15+ |

12

10

12 |

1. Ignore this DFT in calculating total thickness required for protection. 2. Zinc containing (type III) primer normally not used where direct chemical attack predicted. Consult manufacturer. 3. May be MIO pigmented.

4. Small sections vulnerable to 'blocking' if bundled together at this thickness: consult manufacturer. 5. Total system can be applied on site see (4) above. Cost is likely to increase and quality control is more difficult. 6. Maximum resistance to direct chemical attack on paint film and for aesthetic reasons. 7. Maximum durability and chemical resistance. |

Prepare, prime with One-pack Chemical Resistant Primer, bring forward with one coat of Coat 3 type undercoat and apply Coat 4 type finish overall |

These products dry by solvent evaporation alone when unmodified with oil. Adhesion of maintenance systems usually good therefore. |

|

Table 2 Environment C: Typical Protective Systems |

|||||||

|

Interior frequent condensation |

Dry film thickness m m |

Cost comp |

Likely time to first maintenance in years |

Comments upon initial systems |

Repaint - likely system |

Comments upon repaint system |

|

|

(a) |

(b) |

||||||

|

prevent steel corrosion |

maintain appearance hygiene etc |

||||||

|

P5 Off site: Blast to Sa 2½, ISO 8501-1 Medium Profile ISO 8503 Part 1 Coat 1 Blast Primer Type 1, 11 or 111 Coat 2 Two-pack Chemical Resistant Primer

On site: Rectify transit/erection damage with Coat 2 type Primer. Coat 3 Two-pack Chemical Resistant Finish Coat 4 Two-pack Chemical Resistant Finish Total DFT |

15 75

(75)

75 75 223 |

15+ |

10+ |

1. Ignore this DFT in calculating total thickness required for protection.

2. Zinc containing (Type III) primer normally not used where direct chemical attack predicted. Consult manufacturer. 3. Coat 1 may be omitted if blasting is post fabrication. 4. Epoxy or urethane pitch or tar can be used for water resistance. 5. Consult manufacturer for min temperature & max humidity requirements during application and curing. 6. Intervals between coats are critical, consult manufacturer. Ensure relevant information is written into specification. |

Prepare and apply one or two coats of coat 3, two pack chemical resistant finish.

OR

1 coat one-pack chemical resistant undercoat 1 coat one-pack chemical resistant finish. |

Preparation may include light blasting. Remember temperature humidity and intervals between coats are critical.

Refurbishing with one-pack chemical resistant undercoat and finish can be considered. |

|

Note: System P1, page 1 using MIO pigmented undercoat and finish can be considered at dft's of 130-150 m m. It will not resist direct chemical attack or immersion. Likely time to first maintenance - 5 years (columns 'a' and 'b'). |

|||||||

|

Consider also Galvanising - See system G1 (85 m m dft). See page 22 |

|||||||

|

Consider also Metal Spraying - See system AS1/ZS.1 (100 m m dft). See page 22 |

|||||||

Table 2 Environment D: Typical Protective Systems |

|||||||

|

Normal Inland |

Dry film thickness m m |

Cost comp |

Likely time to first maintenance in years |

Comments upon initial systems |

Repaint - likely system |

Comments upon repaint system |

|

|

(a) |

(b) |

||||||

|

prevent steel corrosion |

maintain appearance hygiene etc |

||||||

|

P1

Off site: Blast to Sa 2½, ISO 8501-1 Medium Profile ISO 8503 Part 1

Coat 1 Blast Primer Type 1, 11 or 111 Coat 2 or Oil Based Anticorrosive Primer

Onsite: Rectify transit/erection damage with Coat 2 Primer

Coat 3 Oil Based Undercoat Coat 4 Oil Based Finish

Total DFT Total DFT using micaceous Iron oxide pigmented undercoat Total DFT using Micaceous Iron oxide pigmented undercoat and finish

|

15 50

(50)

25 35

110 130

150 |

7+ 10+

10+ |

5+ 7-12

7-12 |

1. Ignore this DFT in calculating total thickness required for protection. 2. Accurate costing possible.

3. Controlled environment for preparation/priming.

4. Pre or post fabrication priming possible. If post fabrication, omit coat 1. 5. Total system can be applied on site see (4) above. Cost is likely to increase. Quality control is more difficult.

6. The use of micaceous iron oxide pigmented undercoat and finish give better edge protection.

7. Coats 3 & 4 can also be replaced with one coat of a high build finish. |

Prepare and spot prime - oil based anticorrosive Primer plus one or two coats oil based finish. |

Spot priming should be less than 1% Top-coats only refurbished overall so maintenance relatively straight-forward. |

|

Table 2 Environment D: Typical Protective Systems |

|||||||

|

Normal Inland |

Dry film thickness m m |

Cost comp |

Likely time to first maintenance in years |

Comments upon initial systems |

Repaint - likely system |

Comments upon repaint system |

|

|

(a) |

(b) |

||||||

|

prevent steel corrosion |

maintain appearance hygiene etc |

||||||

|

P2 On site: Manual/Mechanical preparation to St 2, ISO 8501-1 Coat 1 Oil Based Anticorrosive Primer Coat 2 Oil Based Undercoat Coat 3 Oil Based Finish Total DFT

Total DFT using micaceous iron oxide pigmented undercoat

Total DFT using micaceous iron oxide pigmented undercoat and finish |

50 25 35 110

135

150 |

6-10

6-10

8-12 |

3-5

3-5

5-7 |

1. light millscale rust in pits will not be removed. This may cause paint detachment before the top coats need refurbishing.

2. The use of micaceous iron oxide pigmented undercoat and finish will give better edge protection. |

Prepare, spot prime with coat 1 type primer, bring forward with coat 2 type undercoat, finish overall with one coat type 2 undercoat and one coat type 3 finish OR 2 coats type 3 finish. OR 1 coat high build finish. |

May require up to 25% priming & bringing forward failure due to millscale detachment unpredictable.

Planned maintenance budgeting difficult. |

|

Table 2 Environment D: Typical Protective Systems |

|||||||

|

Normal Inland |

Dry film thickness m m |

Cost comp |

Likely time to first maintenance in years |

Comments upon initial systems |

Repaint - likely system |

Comments upon repaint system |

|

|

(a) |

(b) |

||||||

|

prevent steel corrosion |

maintain appearance hygiene etc |

||||||

|

P4 Off site: Blast to Sa 2½, ISO 8501-1 Medium Profile ISO 8503 Part 1 Coat 1 Blast Primer Type 1, 11 or 111 Coat 2 Two-pack Chemical Resistant Primer

On site: Rectify transit/erection damage with One-pack Chemical Resistant Primer. Coat 3 One-pack Chemical Resistant Undercoat Coat 4 One-pack Chemical Resistant Finish

Coat 4 Replacing with full gloss One-pack Chemical Resistant Finish gives 25 m m for final coat: Total DFT becomes

OR

Add Coat 5 - full gloss One-pack Chemical Resistant Finish giving additional 25 m m: Total DFT becomes |

15 75

(75) 75 75 225

175

250 |

15+

10+

15+ |

7-10

7+

7-10 |

1. Ignore this DFT in calculating total thickness required for protection.

2. Zinc containing (Type III) primer normally not used where direct chemical attack predicted. Consult manufacturer. 3. May be MIO pigmented.

4. Small sections vulnerable to 'blocking' if bundled together at this thickness: consult manufacturer. 5. Total system can be applied on site. Cost is likely to increase and quality control be more difficult. 6. Maximum resistance to direct chemical attack on paint film and for aesthetic reasons. 7. Maximum durability and chemical resistance. |

Prepare, prime with One-pack Chemical Resistant Primer, bring forward with one coat of Coat 3 type undercoat and apply Coat 4 type finish overall. |

These products dry by solvent evaporation alone when unmodified with oil. Adhesion of maintenance systems usually good therefore. |

|

|

Consider also Galvanising - See system G1 (85 m m dft). See page 22 |

|||||||

|

Consider also Metal Spraying - See system AS1/ZS.1 (100 m m dft). See page 22 |

|||||||

Table 2 Environment E: Typical Protective Systems |

|||||||

|

Normal Coastal |

Dry film thickness m m |

Cost comp |

Likely time to first maintenance in years |

Comments upon initial systems |

Repaint - likely system |

Comments upon repaint system |

|

|

(a) |

(b) |

||||||

|

prevent steel corrosion |

maintain appearance hygiene etc |

||||||

|

P4 Off site: Blast to Sa 2½, ISO 8501-1 Medium Profile ISO 8503 Part 1 Coat 1 Blast Primer Type 11 or 111 Coat 2 One-pack Chemical Resistant Primer

On site: Rectify transit/erection damage with One-pack Chemical Resistant Primer. Coat 3 One-pack Chemical Resistant Undercoat Coat 4 One-pack Chemical Resistant Finish

Coat 4 Replacing with full gloss One-pack Chemical Resistant Finish gives 25 m m for final coat: Total DFT becomes

OR

Add Coat 5 - full gloss One-pack Chemical Resistant Finish giving additional 25 m m: Total DFT becomes |

15 75

(75) 75 75 225

175

250 |

15+

10+

15+ |

12

10

12 |

1. Ignore this DFT in calculating total thickness required for protection.

2. Zinc containing (Type III) primer normally not used where direct chemical attack predicted. Consult manufacturer. 3. May be MIO pigmented.

4. Small sections vulnerable to 'blocking' if bundled together at this thickness: consult manufacturer. 5. Total system can be applied on site. Cost is likely to increase and quality control be more difficult. 6. Maximum resistance to direct chemical attack on paint film and for aesthetic reasons. 7. Maximum durability and chemical resistance. |

Prepare, prime with One-pack Chemical Resistant Primer, bring forward with one coat of Coat 3 type undercoat and apply Coat 4 type finish overall. |

These products dry by solvent evaporation alone when unmodified with oil. Adhesion of maintenance systems usually good therefore. |

|

Table 2 Environment E: Typical Protective Systems |

|||||||

|

Polluted Inland |

Dry film thickness m m |

Cost comp |

Likely time to first maintenance in years |

Comments upon initial systems |

Repaint - likely system |

Comments upon repaint system |

|

|

(a) |

(b) |

||||||

|

prevent steel corrosion |

maintain appearance hygiene etc |

||||||

|

P6

Off site: Blast to Sa 2½, ISO 8501-1 Medium Profile ISO 8503 Part 1

Coat 1 Blast Primer Type 11 or 111 Coat 2 Two-pack Chemical Resistant Primer Coat 3 Two-pack Chemical Resistant Undercoat

Onsite: Rectify transit/erection damage with Coat 2 Primer, bring forward primed areas with coat 3 type undercoat. Coat 4 to-pack Chemical Resistant Finish Total DFT

OR

substitute Coat 4 One-pack Chemical Resistant Finish

Alternative process Total DFT |

15 75 125

(75) (125) 75 275

75

275 |

20

20 |

7-12

7-12 |

1. Ignore this DFT in calculating total thickness required for protection. 2. This coat can be omitted if post fabrication blasting is carried out. 3. Zinc containing (Type III) primer normally not used where direct chemical attack predicted. Consult manufacturer. 4. Consult manufacturer for min temperature and max humidity requirements during application and 'curling'.

5. Interval between coats is critical consult manufacturer. Ensure relevant information is written into specification.

6. This is a useful alternative to a 2-pack paint as the final coat under cold conditions or where there are likely to be delays on site (includes 1-pack moisture-curling polyurethanes) 7. Glossy 1 or 2 pack Chemical Resistant Finishes will give lower DFT's (circa 25 m m). |

Prepare and apply one to two coats of coat 4 type Two-pack Chemical Resistant Finish.

OR

one-pack moisture curing polyurethanes

OR

Prepare and apply one or two coats One-pack Chemical Resistant Finish. |

Preparation may include light blasting. Remember, temperature and humidity and intervals between coats are critical. Refurbishing with a One-pack Chemical Resistant Finish can be considered i.e. chlorinated rubber, vinyl or acrylic resin based. Also 1-pack moisture-curing urethane. |

|

Table 2 Environment E: Typical Protective Systems |

|||||||

|

Polluted Inland |

Dry film thickness m m |

Cost comp |

Likely time to first maintenance in years |

Comments upon initial systems |

Repaint - likely system |

Comments upon repaint system |

|

|

(a) |

(b) |

||||||

|

prevent steel corrosion |

maintain appearance hygiene etc |

||||||

|

P7 Off site: Blast to Sa 2½, ISO 8501-1 Medium Profile ISO 8503 Part 1 Coat 1 Blast Primer Type 11 or 111 Coat 2 One-pack Chemical Resistant Primer

On site: Rectify transit/erection damage with 2 coats One-pack Chemical Resistant Primer. Coat 3 One-pack Chemical Resistant Undercoat Coat 4 One-pack Chemical Resistant Finish Coat 5 One-pack Chemical Resistant Finish Total DFT

Replacing with full gloss One-pack Chemical Resistant Finish gives 25 m m for final coat: Total DFT becomes |

15 100

(50) (50) 75 75 75 325

255(6) |

15+

10+ 15+ |

12

10 12 |

1. Ignore this DFT in calculating total thickness required for protection.

2. Zinc containing (Type III) primer normally not used where direct chemical attack predicted. Consult manufacturer. 3. May be MIO pigmented.

4. Small sections vulnerable to 'blocking' if bundled together at this thickness: consult manufacturer. 5. Total system can be applied on site. Cost is likely to increase and quality control be more difficult. 6. Maximum resistance to direct chemical attack on paint film and for aesthetic reasons. 7. Maximum durability and chemical resistance. |

Prepare, prime with One-pack Chemical Resistant Primer, bring forward with one coat of Coat 3 type undercoat and apply Coat 4 type finish overall (1 or 2 coats). |

These products dry by solvent evaporation alone when unmodified with oil. Adhesion of maintenance systems usually good therefore. |

|

|

G1 Offsite: Galvanise - pr EN 1029 |

85 |

10+ |

Not applicable |

See notes under G1 page 22 |

3 Coat one or two pack chemical resistant paint systems 150-300 m m dft |

See notes under G1 page 22 |

|

|

AS2/ZS2 Off-site zinc or aluminium spray to BS 5269 - sealed |

150 |

zinc 15+ Aluminium 20 |

Not applicable |

See notes under AS1/ZS1 page 22 |

As noted in G1 above |

See notes under AS1/ZS1 page 22 |

|

Table 2 Environment F: Typical Protective Systems |

|||||||

|

Normal Coastal |

Dry film thickness m m |

Cost comp |

Likely time to first maintenance in years |

Comments upon initial systems |

Repaint - likely system |

Comments upon repaint system |

|

|

(a) |

(b) |

||||||

|

prevent steel corrosion |

maintain appearance hygiene etc |

||||||

|

P1

Off site: Blast to Sa 2½, ISO 8501-1 Medium Profile ISO 8503 Part 1 Coat 1 Blast Primer Type 1, 11 or 111 Coat 2 Oil Based Anticorrosive Primer

Onsite: Rectify transit/erection damage with Coat 2 type Primer.

Coat 3 Oil Based Undercoat Coat 4 Oil Based Finish Total DFT Total DFT using a micaceous iron oxide pigmented undercoat Total DFT using micaceous iron oxide pigmented undercoat and finish |

15 50

(50) 25 35 110

130

150 |

8+

8+

8-12 |

3+

3-5

5+ |

1. Ignore this DFT in calculating total thickness required for protection. 2. Accruable costing possible.

3. Controlled environment for preparation/priming.

4. Coat 1 may be omitted if blasting is post fabrication. 5. Total system can be applied on site. Cost is likely to increase. Quality control is more difficult.

6. The use of micaceous iron oxide pigmented undercoat and finish will give better edge protection. |

Prepare, spot prime with coat 2 type primer. Bring forward with coat 3 type undercoat. Finish overall with coat 4 type finish. |

Spot priming should be less than 1%. Bringing forward primed areas with undercoat retains original thickness. |

|

Table 2 Environment F: Typical Protective Systems |

|||||||

|

Normal Coastal |

Dry film thickness m m |

Cost comp |

Likely time to first maintenance in years |

Comments upon initial systems |

Repaint - likely system |

Comments upon repaint system |

|

|

(a) |

(b) |

||||||

|

prevent steel corrosion |

maintain appearance hygiene etc |

||||||

|

P5 Off site: Blast to Sa 2½, ISO 8501-1 Medium Profile ISO 8503 Part 1 Coat 1 Blast Primer Type 1, 11 or 111 Coat 2 Two-pack Chemical Resistant Primer

On site: Rectify transit/erection damage with coat 2 type Primer.

Coat 3 Two-pack Chemical Resistant Finish Coat 4 Two-pack Chemical Resistant Finish

Total DFT |

15 75

(75)

75 75

225 |

15+ |

10+ |

1. Ignore this DFT in calculating total thickness required for protection.

2. Zinc containing (Type III) primer normally not used where direct chemical attack predicted. Consult manufacturer. 3. Coat 1 may be omitted if blasting is post fabrication. 4. Epoxy or urethane pitch or tar can be used for water resistance. 5. Consult manufacturer for min temperature & max humidity requirements during application and curling.

6. Intervals between coats are critical, consult manufacture. Ensure relevant information is written into specification. |

Prepare and apply one to two coats of coat 3, Two-pack chemical resistant finish.

OR

1 coat One-pack chemical resistant undercoat 1 coat One-pack chemical resistant finish. |

Preparation may include light blasting. Remember temperature, humidity and intervals between coats are critical. Refurbishing with One-pack chemical resistant undercoat and finish can be considered. |

|

|

G1 Offsite: Galvanise - pr EN 1029 |

85 |

20 |

Not applicable |

See notes under G1 |

3 Coat one or two pack chemical resistant paint systems 150-300 m m dft |

See notes under G1 |

|

|

AS2/ZS1 Off-site zinc or aluminium spray to BS 5269 - sealed |

150 |

20 |

Not applicable |

See notes under AS1/ZS1 |

As noted in G1 above |

See notes under AS1/ZS1 |

|

Table 2 Environment G: Typical Protective Systems |

|||||||

|

Polluted Coastal |

Dry film thickness m m |

Cost comp |

Likely time to first maintenance in years |

Comments upon initial systems |

Repaint - likely system |

Comments upon repaint system |

|

|

(a) |

(b) |

||||||

|

prevent steel corrosion |

maintain appearance hygiene etc |

||||||

|

P6

Off site: Blast to Sa 2½, EN 8501-1 Medium Profile ISO 8503 Part 1

Coat 1 Blast Primer Type 11 or 111 Coat 2 Two-pack Chemical Resistant Primer Coat 3 Two-pack Chemical Resistant Undercoat

Onsite: Rectify transit/erection damage with Coat 2 Primer, bring forward primed areas with coat 3 type undercoat. Coat 4 two-pack Chemical Resistant Finish Total DFT

OR

substitute Coat 4 One-pack Chemical Resistant Finish

Alternative process Total DFT |

15 75 125

(75) (125) 75 275

75

275 |

10+

10+ |

10

7-12 |

1. Ignore this DFT in calculating total thickness required for protection. 2. This coat can be omitted if post fabrication blasting is carried out. 3. Zinc containing (Type III) primer normally not used where direct chemical attack predicted. Consult manufacturer. 4. Consult manufacturer for min temperature and max humidity requirements during application and 'curling'.

5. Interval between coats is critical consult manufacturer. Ensure relevant information is written into specification.

6. This is a useful alternative to a 2-pack paint as the final coat under cold conditions or where there are likely to be delays on site (includes 1-pack moisture-curling polyurethanes) 7. Glossy 1 or 2 pack Chemical Resistant Finishes will give lower DFT's (circa 25 m m). |

Prepare and apply one to two coats of coat 4 type Two-pack Chemical Resistant Finish.

OR

one-pack moisture curing polyurethanes

OR

Prepare and apply one or two coats One-pack Chemical Resistant Finish. |

Preparation may include light blasting. Remember, temperature and humidity and intervals between coats are critical. Refurbishing with a One-pack Chemical Resistant Finish can be considered i.e. chlorinated rubber, vinyl or acrylic resin based. Also 1-pack moisture-curing urethane. |

|

Table 2 Environment G: Typical Protective Systems |

|||||||

|

Polluted Coastal |

Dry film thickness m m |

Cost comp |

Likely time to first maintenance in years |

Comments upon initial systems |

Repaint - likely system |

Comments upon repaint system |

|

|

(a) |

(b) |

||||||

|

prevent steel corrosion |

maintain appearance hygiene etc |

||||||

|

P8 Off site: Blast to Medium Profile ISO 8503 Part 1 Coat 1 Blast Primer Type 11 or 111 Coat 2 One-pack Chemical Resistant Primer

On site: Rectify transit/erection damage with 2 coats One-pack Chemical Resistant Primer. Coat 3 One-pack Chemical Resistant Undercoat Coat 4 One-pack Chemical Resistant Finish Coat 5 One-pack Chemical Resistant Finish Total DFT

Replacing with full gloss One-pack Chemical Resistant Finish gives 25 m m for final coat: Total DFT becomes |

15 100

(50) (50) 75 75 75 325

275(6) |

15+

10+ |

12

10 |

1. Ignore this DFT in calculating total thickness required for protection.

2. Zinc containing (Type III) primer normally not used where direct chemical attack predicted. Consult manufacturer. 3. May be MIO pigmented.

4. Small sections vulnerable to 'blocking' if bundled together at this thickness: consult manufacturer. 5. Total system can be applied on site. Cost is likely to increase and quality control be more difficult. 6. Maximum resistance to direct chemical attack on paint film and for aesthetic reasons. 7. Maximum durability and chemical resistance. |

Prepare, prime with One-pack Chemical Resistant Primer, bring forward with one coat of Coat 3 type undercoat and apply Coat 4 type finish overall (1 or 2 coats). |

These products dry by solvent evaporation alone when unmodified with oil. Adhesion of maintenance systems usually good therefore. |

|

|

G1 Offsite: Galvanise - pr EN 1029 |

140 |

10+ |

Not applicable |

See notes under G1 |

3 Coat one or two pack chemical resistant paint systems 150-300 m m dft |

See notes under G1 |

|

|

AS2/ZS2 Off-site zinc or aluminium spray to BS 5269 - sealed |

150 |

15+ |

Not applicable |

See notes under AS1/ZS1 |

As noted in G1 above |

See notes under AS1/ZS1 |

|

Table 3 Methods of blast-cleaning (ISO 8504-1 and 2)

|

Methods |

Advantages |

Disadvantages |

|

Dry methods using compressed air or centrifugal force |

||

|

Automatic plants based on centrifugal throwing of the abrasive |

High production rates, lowest costs, no moisture problems. Can be coupled to automatic application of primer, dust problems contained. |

High capital cost, high maintenance cost, lack of flexibility, ie. not suitable for recessed areas etc. |

|

Open blasting based on propelling the abrasive with compressed air. |

Simple to operate, very flexible and mobile in use both indoor cabinets or special rooms or on site. Low capital and maintenance costs. |

High cost of compressed air, low efficiency, liable to moisture entrainment from the compressed air, manually operated and a variable profile can result, operator requires protective clothing, serious dust problems. |

|

Vacuum blasting based on propelling the abrasive with compressed air and immediately recycling by suction from the blast-cleaned surface. |

No dust problems, no special protective clothing for operators, fairly low capital costs. |

Can be very slow and therefore expensive, particularly on awkward profiles and girder sections. Where flat-plate or gun-head automation is possible it may be considered, but liable to moisture entrainment from the compressed air. |

Table 3 Methods of blast-cleaning - Cont'd.

|

Methods |

Advantages |

Disadvantages |

|

Wet methods (hydroblasting) |

||

|

Open blasting based on projecting water at very high pressure. |

Simple to operate, very flexible and mobile in use, suitable for removing soluble containments. At very high pressure can remove mill-scale, no dry dust hazards. |

Slow if firmly held containments are to be removed, dangerous at very high pressure if proper precautions are not taken, limitation of drying surface before painting unless approved water-based or moisture tolerant primers are used, requires availability of water and drainage, operators require protective clothing. |

|

Open blasting based on projecting water at high pressure and entraining abrasive into the water stream. |

Simple to operate, very flexible and mobile in use, suitable for removing all firmly held contaminants as well as soluble contaminants. |

Dangerous at very high pressure if proper precautions are not taken, limitation of drying surface before painting unless approved water-based or moisture tolerant primers are based, required availability of water and drainage, operators require protective clothing. |

|

Open blasting based on injecting low pressure water into a compressed air stream which is carrying an abrasive. |

As above. |

High cost of compressed air, limitation of drying surface before painting unless approved water-based or moisture tolerant primers are used, dust hazard reduced, operators require protective clothing. |

|

Open blasting using steam-cleaning. |

As above. |

Similar to the above according to whether abrasive is or is not entrained. |

|

Table 4 Classification of abrasives used for cleaning steel |

||||

|

Abrasive |

Hardness |

Normal usage |

Advantages |

Disadvantages |

|

Chilled iron-grit ISO 11124-2 |

60 to 80 RC |

Captive blasting and open blasting with recovery systems |

Relatively cheap, cleans very quickly, will chip under repeated impact with work surface, presenting fresh cutting edges |

Breaks down fairly quickly. In centrifugal wheel plants, special protection is required to reduce wear on moving parts |

|

Chilled iron-shot |

60 to 80 RC |

Captive blasting only |

Relatively cheap, very hard, should break down to grit in use |

As chilled iron-grit. Because of ricochet effect is not suitable for open blasting or in open cabinets |

|

High duty chilled iron-grit or iron-shot |

55 to 64 RC |

Captive blasting and open blasting with recovery |

Breaks down less quickly than chilled iron |

More expensive than chilled iron, rendered spherical in use, poorer and slower rate of cleaning than chilled iron |

|

Heat-treated chilled iron-grit or iron-shot |

30 to 40 RC |

As high-duty |

As high-duty |

As high-duty |

|

Steel grit |

60 to 67 RC 47 to 53 RC |

Captive blasting mainly |

Does not bread down so quickly as chilled iron, causes less wear in centrifugal wheel plant |

More expensive than chilled iron, rendered spherical in use and is less efficient, supplied in various hardnesses but at best is not so hard as chilled iron-grit and therefore cleans more slowly |

|

Steel shot |

41 to 49 RC |

Captive blasting only |

As for steel grit |

As for steel grit, produces a more rounded surface profile than grit, ricochet effect makes it unsuitable for open blasting |

|

Cut steel wire ISO 11124-5 |

41 to 52 RC |

Captive blasting only |

As for steel shot and grit, wears down as fairly even sizes |

High cost, rendered spherical in use and slower cleaning than chilled iron |

|

Table 4 Classification of abrasives used for cleaning steel - Cont'd. |

||||

|

Abrasive |

Hardness |

Normal usage |

Advantages |

Disadvantages |

|

Aluminium oxide (corundum) ISO 11126-7 |

|

Not common in the United Kingdom |

Extremely hard |

Expensive, hardness of dust is a danger to machinery unless used in sealed captive plant |

|

Copper slag ISO 11126-3 |

|

Open blasting only |

Cheap, no silicosis hazards |

Initial particles rather coarse, breaks down to dust very quickly, angular particles tend to embed in workplace |

|

Iron slag ISO 11126-6 |

|

Open blasting only |

As for copper slag |

As for copper slag |

|

Sand (Olivine) ISO 11126-8 |

|

Open blasting |

Cheap |

In United Kingdom, Factory Inspector's approval is required, danger of silicosis |

See Table 4

International Standards for Metallic and Non-Metallic Blast-Cleaning Abrasives

A.1 Requirements and test methods for metallic blast-cleaning abrasives are contained in ISO 11124 and ISO 11125.

ISO 11124 consists, at present, of the following parts, under the general title:

Preparation of steel substrates before application of paints and related products -Specifications for metallic blast-cleaning abrasives:

- Part 1: Introduction

- Part 2: Chilled-iron grit

- Part 3: High-carbon cast-steel shot and grit

- Part 4: Low-carbon cast-steel shot

- Part 5: Cut steel wire

ISO 11125 consists, at present, of the following parts, under the general title:

Preparation of steel substrates before application of paints and related products -Test methods for metallic blast-cleaning abrasives:

- Part 1: Sampling

- Part 2: Determination of particle size distribution

- Part 3: Determination of hardness

- Part 4: Determination of apparent density

- Part 5: Determination of percentage defective particles and of microstructure

- Part 6: Determination of foreign matter

- Part 7: Determination of moisture

A.2 Requirements and test methods for metallic blast-cleaning abrasives are contained in ISO 11126 and ISO 11127.

ISO 11126 consists, at present, of the following parts, under the general title:

Preparation of steel substrates before application of paints and related products -Specifications for metallic blast-cleaning abrasives:

- Part 1: Introduction

- Part 2: Silica sand

- Part 3: Copper refinery slag

- Part 4: Coal furnace slag

- Part 5: Nickel refinery slag

- Part 6: Iron furnace slag

- Part 7: Fused aluminium oxide

- Part 8: Olivine sand

ISO 11127 consists, at present, of the following parts, under the general title:

Preparation of steel substrates before application of paints and related products -Test methods for metallic blast-cleaning abrasives:

- Part 1: Sampling

- Part 2: Determination of particle size distribution

- Part 3: Determination of apparent density

- Part 4: Assessment of hardness by a glass slide test

- Part 5: Determination of moisture content

- Part 6: Determination of water-soluble contaminants by conductivity measurement

- Part 7: Determination of water-soluble chlorides

APPENDIX 1 FACTORS AFFECTING THE CHOICE OF COATING SYSTEMS

QUESTIONS RELATED TO DESIGN, USE AND SITE REQUIREMENTS

Function

a. What is the main function of the structure?

b. What are the secondary functions of the structure?

Life

a. For how long is it required to fulfil this function?

b. What is the life to first maintenance? (It may not be possible to decide this until further questions have been answered).

Environment

a. What is the general (atmospheric) environment at the site of the structure?

b. What localised effects exist or are to be expected, e.g. fumes from stacks?

c. What other factors may affect the structure, e.g. surface temperature and abrasion?

Appearance

a. What is the structure required to look like (colour and finish)?

b. Is the final coat to be applied on site?

Special Properties

a. What special properties are required of the coating, e.g. coefficient of friction?

Maintenance

a. What access is there going to be for effective maintenance?

b. What is the possibility of effective maintenance?

Health and Safety

a. Are any problems to be taken into account during initial treatment?

b. Are any problems to be taken into account during maintenance treatment?

Tolerance

Does the coating need to be tolerant of:

a. indifferent surface preparation

b. indifferent application techniques

c. departures from specification?

QUESTIONS RELATING TO COATING SYSTEMS

Coating systems

a. What coating systems are suitable?

b. Are these systems readily available?

c. Are the system elements mutually compatible?

d. If paints, can the coats be applied by:

e. Can the system, or parts, be applied on site?

Coating facilities

a. Are the coating facilities readily available:

b. Do they cover all sizes and shapes of fabrication?

c. Do they permit speedy application?

d. Do the facilities permit work to adequate standards?

Compatibility with engineering and metallurgical features

a. Is the design and jointing of the structure compatible with the preferred coating technique?

b. Does surface preparation (blasting, pickling) or application of coating affect the mechanical properties of the steel in any way that matters?

c. Is the system compatible with cathodic protection?

Delays

What delays should be allowed between:

a. fabrication and first protective coating;

b. application of primer and undercoat;

c. application of undercoat and finishing coat;

d. final shop coat and erection;

e. erection and final treatment?

Transport, storage and handling

How well does the coating withstand:

a. excessive or careless handling;

b. abrasion and impact;

c. early stacking;

d. exposure to seawater during transit?

Experience

a. What is known of the consistent performance of the coating?

Export

a. What special precautions should be taken when the steelwork is exported?

Maintenance

a. Is the deterioration of the coating rapid and serious if maintenance is delayed?

b. What is the likely maintenance system? (Including surface preparation).

Costs

a. What are the approximate costs of:

b. What are the approximate costs of maintenance?

APPENDIX 2 PAINT TYPES

BLAST PRIMERS

These primers have been the cause of some confusion; they are therefore dealt separately here.

They are used pre- or post-fabrication, normally in-shop and under controlled conditions.

The most important types are:

Type I

One or two-pack polyvinyl butryal/phenolic: zinc tetroxychromate: DFT 15-20mm.

Type II

Two-pack epoxy: zinc phosphate or zinc tetroxychromate: DFT 25mm.

Type III

Two-pack epoxy: zinc metal DFT 10-20mm. Note: Metallic zinc coatings (including zinc spray and galvanising) can give rise to health hazards even in open shop conditions when welded or flame cut.

One pack zinc metal and two-pack zinc ethyl silicate coatings are available for specific uses.

Very often the anti-corrosive primer which is the first coat of a chosen system is specified as the post-fabrication primer.

DRYING OIL BASED PAINTS

These paints dry by reaction with atmosphere oxygen. Widely used, they are based on vegetable or fish oils suitably treated, e.g. by heat, and reinforced with synthetic or naturally occurring resins. They do not withstand direct chemical attack nor immersion conditions.

PRIMERS

There are two basic types, relatively slow drying products whose use is limited to site application and faster-drying versions which can be used in-shop and on site. In general the latter type have lower volume solids. All are for use beneath oil-based systems; some can be used beneath one pack chemical resistant systems.

Typical binders are:

Typical anti-corrosive pigments include:

Zinc phosphate or zinc chromate with red lead and calcium plumbate still used in primers designed for site use. All but zinc phosphate impose limitations in use.

Dry film thicknesses vary between 25-75mm depending upon volume solids, application method and service use.

Undercoats (Intermediate coats)

With the exception of unreinforced drying oils, all the binders noted under 'Primers' may be used.

Pigmentation is typically titanium dioxide for whites and tints, organic and inorganic chemically resistant pigments for colours. Micaceous iron oxide pigments are used to give increased film thickness, improved edge cover and good weather resistance.

Dry films are between 25-50mm thick depending upon volume solids, application method and service use.

These products are for use beneath oil based gloss and micaceous iron oxide finishes.

Finishes

High gloss finishes in BS 4800 and RAL colours and low-sheen subdued colours in micaceous iron oxide paints have excellent weather resistance but do not resist direct chemical attack or complete immersion in water.

Typical binders are oil or urethane modified alkyds, epoxy esters and oil modified phenolics.

Pigments are various grades of rutile titanium dioxide, light-fast coloured pigments and micaceous iron oxide or aluminium.

Dry film thicknesses vary between 25-50mm. In this respect, the same criteria apply as for undercoats.

ONE-PACK CHEMICAL RESISTANT PAINTS

All but one of the products in this range dry by solvent evaporation. The exception, moisture-curing polyurethanes, will be dealt with last. A wide range of film formers is available, typically plasticised chlorinated rubber, solution vinyl copolymers and acrylic resins, acrylated polymers. The differences between products based on these resins and others are subtle with individual manufacturers having built up experience over many years with one or two resin systems.

The main characteristics which they have in common are excellent water resistance (including immersion), good resistance to inorganic acids and adequate alkali resistance. In this latter respect, two-pack chemical resistant systems withstand severe attack better. Theoretically, no paint based on the resins quoted in the previous paragraph are proof against attack by organic acids, animal fats, etc., but in practice there are many examples where they have proved more than adequate. Paint manufacturers will advise on specific cases.

Because these paints dry by solvent evaporation they form films at low temperatures and will dry satisfactorily in polluted atmospheres. Intercoat adhesion both initially and for maintenance is good because the resins remain soluble in the solvents used in the paints. Conversely, solvent resistance is relatively poor. Maximum heat resistance is circa 65°C.

In this group must be included waterborne resin systems, e.g. vinyl acrylic copolymers. Although relatively new (they were introduced within the last decade) they show great promise, particularly as metal primers. Since they coalesce rather than forming a film by simple solvent loss, their mechanical properties are better than might be expected from a one-pack paint.

Also in the group are one-pack moisture-curing polyurethane resin-based paints. These must not be confused with oil or alkyd containing products which are 'reinforced' by the addition of a urethane component. Moisture-curing varieties dry like two-pack paints, undergoing a complex chemical reaction in which moisture acts as the 'curing' agent. Once cured, these paints possess most of the attributes associated with two-pack polyurethane paints. A significant advantage is their ability to form films at low temperatures. Obviously this feature must be exploited with caution; water or ice formed at the paint/surface interface must degrade its performance.

Primers are available for shop and site application based on all these resin systems. Since their corrosion inhibiting properties are inferior to primers irrespective of which inhibitive pigment is chosen, some manufacturers produce an oil-modified primer specifically formulated for use in a one-pack chemical resistant paint process (excluding moisture curing polyurethanes). Usually these are not recommended for severe exposure or immersed conditions. They are particularly useful for site application.

Zinc phosphate pigments are widely used as the inhibitive pigment.

Dry film thicknesses vary between 25-65mm depending upon volume solids, application method and service use.

Undercoats (Intermediate coats)

Any of the resins noted above may be used. These coats are both weather and chemically resistant; indeed many proprietary products are designated 'Thick Coatings' and suitable both as intermediate and finishing coats.

Rutile titanium dioxide pigments are widely used in whites and tints. Light fast and chemically resistant pigments are used for colours, with micaceous iron oxide used both for its weather resistance and ability to improve the mechanical properties of the paint film.

Dry film thicknesses between 50-100mm per coat depend upon volume solids, dimensions and complexity of the steelwork, application method, surface and ambient temperatures. Additionally, solvent release is relatively slow and inhibits the thickness which can be safely applied to avoid solvent entrapment producing bubbles or pinholes.

Finishes