ESDEP WG 16

STRUCTURAL SYSTEMS: REFURBISHMENT

To give general definitions of the different levels of refurbishment and associated activities. To describe the various forms of temporary works required on such projects and to provide an introduction to the problems of strengthening structures by means of steel. To identify the advantages of steel in these activities.

None.

Lecture 16.2: Transformation and Repair

Lecture 16.3: Re-use of Buildings

The future of the building industry will be increasingly concerned with the strengthening, re-use and transformation of old buildings. Steel has an important role in all aspects of such construction: ensuring safety, for repair, strengthening and restructuring. Temporary works are often necessary in connection with these activities and various systems can be used. A number of specialised techniques have been developed for strengthening building structures of all materials. In all cases steelwork offers unique advantages of prefabricated, dry construction, speed and ease of installation, immediate load carrying resistance, and high strength to weight ratio.

The building industry today is looking with particular interest at the restoration of our architectural heritage. The future of this industry will be extensively concerned with the strengthening, re-use and modernisation of old buildings, which may have been damaged by, for instance, atmospheric action or earthquakes, or require modifications to allow a change of use, replacement of non-structural components such as services, or to provide additional accommodation. Ideally the need for refurbishment should be considered as part of the original design by providing flexibility and adaptability within the structural form used. Unfortunately many of the buildings now being refurbished were designed and built many years ago before the introduction of features such as modern air-conditioning systems, telecommunication networks and lightweight cladding. Even if the needs for re-equipping buildings had been taken into account, they could hardly be expected to have predicted the enormous advances which have taken place and the need to replace major components of building installations after relatively short service. Ease of refitting buildings has now become a major design consideration.

Some of the buildings to be refurbished may be of a common type, but many are of historic and architectural interest. In all cases steel is an ideal material for refurbishment works - both from a structural and architectural point of view.

Steelwork provides a suitable basis for all forms of refurbishment and reconstruction work, both temporary and permanent. Because it is fabricated off-site, space requirements on what are often very restricted and congested sites are minimised. It can be installed quickly, in many cases without the need for heavy lifting equipment, because it is a relatively lightweight form of construction. Disruption to normal operations within the existing building are minimised because wet trades can be eliminated and the new structure is able to carry load immediately without propping.

In any remedial or reconstruction work, an initial appraisal of the existing structure needs to be carried out [1]. The examination needs to consider whether or not the existing building is suitable for upgrading and whether existing structural members can carry new loads or whether, if necessary, they can be repositioned to suit new planning requirements.

This lecture outlines the range of refurbishment activities which may be necessary. It describes in detail the types of temporary works which are associated with refurbishment. Methods for strengthening existing masonry, timber, concrete, iron and steel structures are considered. More extensive refurbishment activities involving structural alterations and restructuring are dealt with in detail in Lectures 16.2 and 16.3.

From the structural point of view, steel can be widely used in all forms of remedial work to existing structures. These uses can be described in order of importance according to the following classification: ensuring safety, for repair, strengthening and restructuring.

Ensuring safety is also the first in chronological order, when action of a temporary nature is required. Urgent action may be required in the case of structures which have become unsafe due to accidental damage, excessive loadings or simply prolonged, unchecked deterioration. Temporary works may also be necessary prior to starting any other permanent construction activity. In all cases the aim is to achieve adequate short term safety for both the public and the site.

After making safe, the next stages, both logically and chronologically, are repair and strengthening.

Repair involves carrying out a series of operations to the fabric of a damaged building to restore its former structural efficiency. Strengthening on the other hand, involves improving structural performance in order to enable the building to fulfil new functional requirements (for example, heavier load conditions associated with a change of use) or environmental conditions (such as location in an area recently declared to be subject to seismic conditions).

Strengthening operations can be subdivided into:

There are numerous strengthening systems based on the use of steel which can be used to restore masonry, timber, reinforced concrete, iron and steel structures.

Structural alterations, which consist of the partial or total modification of the functional distribution and volumetric dimensions, together with all the other characteristics of the building, including the original structural system, are associated with more extensive construction work. This work may involve opening up internal spaces, inserting additional structure, extending vertically, and removing parts of the existing building in order to reduce loads.

Increasingly refurbishment involves complete restructuring of a building with only the facade retained from the original construction. This process requires careful consideration of the stability of the facade during reconstruction, demolition of the interior and building the new structure, including connections to the retained facade.

The choice of steel in refurbishment work is based largely in its high mechanical performance. When a building of historical interest is to be restored, the operation is most delicate and the use of structural steel has further advantages. Such work involves the conservation of existing buildings and their integration with the necessary new works. It may be appropriate to make a clear distinction between the existing building and the modern character of the new work, and to use a system which can be removed at a later date without damaging the existing structure.

Various international restoration recommendations recognise that use of construction methods of the past may no longer be appropriate or possible for many reasons, above all technological but also relating to sentiment, construction tradition, new functional requirements and lack of availability of old materials. These recommendations, particularly in cases which involve partial reconstruction, also indicate the need to use well adapted technologies and materials in an unambiguously modern way.

Steel satisfies these requirements and is therefore widely used in restoration work on all kinds of ancient monuments and buildings.

Temporary works are normally the responsibility of the building contractor rather than the structural engineer. However an understanding of the principal points which need consideration in designing propping systems is important to all involved with these activities. The main problem is to ensure that any temporary works supporting the existing structure do not obstruct future final works. Suitable systems must offer ease of erection and provide for flexibility of construction. For this purpose, steel, with its prefabricated form, enables standard solutions to be designed and tailored to suit specified requirements.

The most common areas where the structural engineer will be involved in temporary works is in needling and propping to provide a system for carrying vertical loads. Slide 1 shows the structure made of hot-rolled steel sections which was designed for the temporary shoring of the stone columns at the entrance hall of Palazzo Carigliano in Turin. The restoration work involved the replacement of the old floors with new ones consisting of IPE and HE sections with profiled steel sheets acting as formwork for a cast slab.

Slide 1 : Palazzo Carigliano, Turin, Italy

Where openings are being formed in masonry walls the loads from above need to be carried down to temporary foundations whilst the new support members are being inserted. If steel beams are used as needles it is important that bearing and buckling at support points of the needles are checked and correct details employed (Slide 2).

Slide 2 : Needles and props used for temporary vertical support to wall during reconstruction work.

It is often necessary to provide temporary lateral support for stabilising walls which are to be retained during the demolition phase of a refurbishment contract. There are several different systems used for this - raking shores, scaffolding in the form of shores and as lattices, and rectangular steel frames arranged horizontally and vertically.

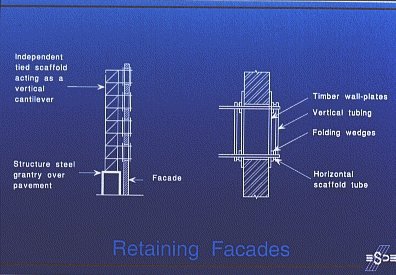

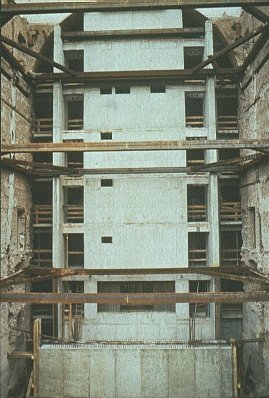

The support system to retain facades (Slide 3) can be positioned either internally or externally. If positioned internally it should be installed through pockets cut in the existing structure, and seated on temporary foundations before any major demolition takes place. Obviously the need to avoid obstruction to future frame positions and foundation positions is of paramount importance.

Slide 3 : Facade retention systems

If the temporary works are positioned externally then, apart from the removal of windows, the works can be positioned prior to any demolition taking place. However in crowded city centres it is important to provide access and protection to the public in the form of steel gantries over pavements. Typically horizontal lattices climb the free standing masonry wall and span the loads from the wind back to the vertical lattices (Slide 4). Clearly in such cases the external works create no obstruction to the insertion of the new frame.

Slide 4 : Facade retention

In some cases the temporary works may be positioned partly internally and partly externally. In all cases it is clearly important to ensure that they do not obstruct the new foundations, particularly where piling operations will be necessary to insert multiple piles and a pile cap.

An alternative is to use flying shores spanning between the side walls of the building. These shores can be inserted prior to any demolition apart from cutting pockets through light partitions which may be in the way. For longer spans a central support prop or tower may be required. This support will need to have a temporary foundation to take the loads which it will carry (Slide 5). Such a system of temporary bracing of perimeter walls, by means of horizontal rings of steel sections fixed to the walls, was used during the restructuring of the old Moller theatre in Darmstadt, Germany, for use as a state record office (Slide 6). Proprietary steel flying shore systems are also available.

Slide 5 : Flying shore system

Slide 6 : The old Moller Theatre in Darmstadt, Germany

One problem is the need to thread new steel members through the temporary works. The positioning of the propping needs, therefore, to be carefully considered to avoid obstruction to the new framing.

It may also be necessary to provide in-plane stability to walls during reconstruction. In this case facades can be tied to prevent spread from wind forces by using horizontal or inclined steel sections fixed as straps around the perimeter of the building (Slide 7).

Slide 7 : Temporary steel ties to prevent spread across facade

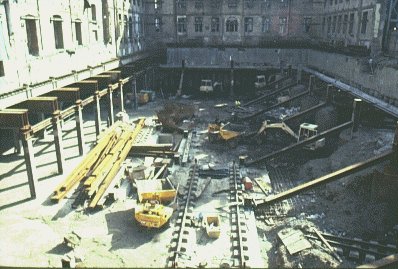

In many cases a variety of temporary works is required. For instance if a facade is to be retained and a new basement constructed, a combination of raking shores, needling and propping will be necessary (Slide 8).

Slide 8 : Construction of a new basement - to achieve the maximum lettable floor area - as part of a refurbishment contract in the centre of London.

All common building materials are prone to damage or decay over a prolonged period, and it may be necessary, therefore, to undertake remedial action to strengthen weakened structures. Changes of building use may require load carrying resistances to be enhanced to allow increased imposed loads. In either case steel can be used in a variety of ways to strengthen existing structures. Some of these are described below.

Strengthening masonry may be concerned with increasing the load carrying resistance with regard to vertical loads as well as horizontal actions due to settlement of foundations, asymmetry of geometry or load, or - more seriously -seismic action.

Vertical load carrying resistance can be improved by the following methods:

Slide 9 : Post Office, Leeds, UK

Strengthening walls or columns to withstand horizontal actions can be provided as follows:

Slide 10 : Braced wall for the reconstruction of the Cathedral of Montemarano in Avellino, Italy

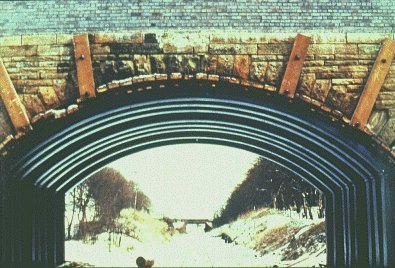

Masonry arches can be strengthened by using steel sections bent to suitable radii and installed underneath the existing structure (Slide 11).

Slide 11 : Masonry arches can be strengthened by introducing steel members curved to the required radius, under the masonry, as shown in this bridge at Airdrie, Scotland.

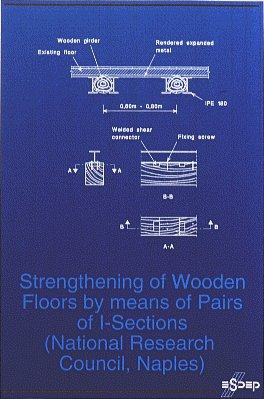

As an alternative to complete replacement, timber floors, which are especially common in old buildings, may be strengthened quite easily by the use of steel sections using various constructional methods (Slides 12 and 13):

Slide 12 : (a) Strengthening of wooden floors by means of pairs of I-sections

Slide 13 : Strengthening of timber beams at National Research Council, Naples, Italy

An interesting variant of this latter method was used in the restoration of the Este Fortress of St. Martino in Rio, Reggio Emilia. The aim was to safeguard the old wooden floor by creating a new steel structure to take over its load-bearing function: I-sections were placed in suitable channels made in the top of the wooden beams and a concrete slab cast on profiled steel sheets. Composite action between the steel beam and concrete slab was achieved by means of shear stud connectors welded to the top of the steel beams [2].

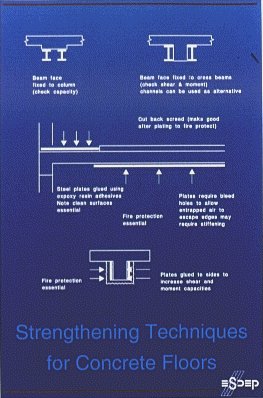

Concrete structures may also be strengthened using steel sections, as shown in Slide 14. Either universal beam or universal column sections may be positioned under or adjacent to existing concrete beams and grouted into position with epoxy resin mortar. Alternatively steel plates may be bonded to the top and bottom surfaces of concrete slabs or to the sides of concrete beams to increase the shear and bending strength. The use of these steel plates is a relatively straightforward technique; however, corrosion and fire protection must both be considered. Stiffeners may be required along the sides of plates to avoid distortion during the fixing process and bleed holes will need to be left to ensure a complete coverage of the epoxy resin mortar.

Slide 14 : Strengthening concrete floor structures using steel sections

Concrete and hollow tile floors can be strengthened in a similar way or by inserting I-beams between the concrete ribs in suitable cavities (Slide 15).

Slide 15 : CNR Research Area, Arco-Felice, Pozzuoli, Italy

In strengthening concrete flat slab structures, steel sections may need to be cut and fabricated to suit the differing depths of the concrete slab and shear heads (Slide 16).

Slide 16 : Strengthening a concrete flat slab floor using steel sections

Storey-high steel lattice girders may be needed where it is necessary to transfer very heavy loads back to the concrete columns.

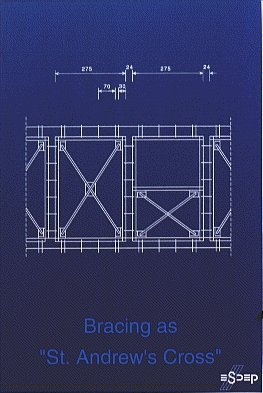

A very effective use of structural steel in strengthening reinforced concrete framed structures against earthquakes consists of introducing shear panel walls, which have a dual purpose. They considerably increase the resistance of the frame to horizontal forces and at the same time balance the distribution of internal rigidity with respect to the shear centre so as to minimise dangerous torsional vibrations. The shear walls with lattice steel bracing (Slide 19) are made by connecting steel sections to the beams and columns of the reinforced concrete frame. Inside the frame diagonals and counter-diagonals are arranged in the classic St Andrew's cross pattern (Slide 17) or in other patterns more suited to the use of the building (Slide 18). The presence of a single diagonal for each rectangular panels makes it possible to provide door or window openings. Such a system was used in the seismic strengthening of the reinforced concrete structure at the Carderelli Hospital Complex in Naples, Italy. Both the frame and the diagonal trusses are usually made of I sections [2].

Slide 19 : Different types of lattice steel bracings

Slide 17 : Strengthening an existing reinforced concrete frame structure using St. Andrew's cross-bracing

Slide 18 : St. Andrews cross-bracing inserted over two storeys, allowing for door and window openings.

Allowable stresses for iron and steel in building have gradually increased as improvements in manufacture and production have taken place. In the later 1800s allowable stresses for cast iron were around one ton per square inch and for wrought iron around five tons per square inch. Current allowable stresses for steel, which are given in the latest standards for design of steelwork, are very much higher. The strength of existing iron and steel structures obviously needs to be considered in relation to the standards in force at the time of original construction, although with extensive testing it may be possible to justify a slight increase in the allowable stresses specified at that time.

In the United Kingdom guidance is available on the allowable stresses for all sections which are known to have been rolled since the late 1880s in cast iron, wrought iron and steel [3].

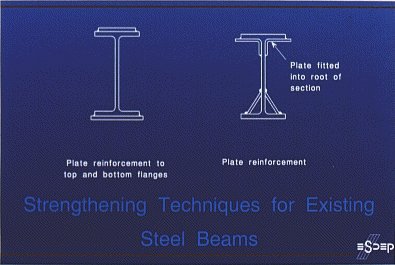

When considering the strengthening of existing steel beams various techniques can be employed (Slide 20):

Slide 20 : Strengthening iron and steel beams using steel sections

In all cases the connection between the new and existing must be carefully considered. If bolting is to be used the initial loss of strength of the existing member whilst the bolt holes are drilled will need consideration, as this temporary condition may prove to be critical. If the alternative of welding is used then the specification of the welding technique must be compatible with the existing material. A few basic rules to be considered are:

One point to be borne in mind is that steel is a re-usable material; although the building being examined may have been built in the 1950s, for instance, the steel may have been second hand at the time and could well have been produced during the 1910 to 1930 period. Some steel sections should therefore always be tested before deciding on the final specification.

Once the specification has been decided on a few points which need consideration in detailing the site welding are as follows:

[1] 'Appraisal of Existing Structures', Institution of Structural Engineers, London, 1980.

[2] 'Refurbishment', ARBED, Luxembourg, 1989.

[3] 'Historical Structural Steelwork Handbook', British Constructional Steelwork Association, London, 1984.