ESDEP WG 1A

STEEL CONSTRUCTION:

ECONOMIC & COMMERCIAL FACTORS

To introduce the history of steelmaking and steelmaking today. To describe how steel is produced and the standardisation of steel products. To summarise the consumption of steel in building and civil engineering worldwide.

Lecture 1A.1: Introduction to Steel's Role in Construction in Europe

Lecture 1A.3: Introduction to Structural Steel Costs

Lecture 1A.4: The European Building Market

The history of steelmaking is introduced and the developments described which have led to modern steel production. The essentials of modern production are summarised.

World production of steel is described and the European standardisation of steel products (Euronorms) is introduced. The use of steel in civil engineering and building in the different regions of the world is discussed.

Of the construction materials in common use, steel is the one which offers the greatest load resistance for the smallest section. It is primarily an alloy of iron and carbon.

The production of industrial steel is relatively recent, dating back only one hundred and twenty years or so. However, ferrous metals, of which the main component is iron, have been known since antiquity. The first examples were of iron found in its natural state in Sumer, capital of the ancient Babylonian civilization. The first proof of actual production of iron goes back to the Chalybes, a tribe living on the South Coast of the Black Sea around the XVIIth Century BC.

The use of iron spread into Europe and Asia, but it was only in the Middle Ages that any significant improvements in manufacturing can be noted with the introduction of tuyeres, which blew air from bellows powered by hydraulic energy. Before the discovery of steel, iron was frequently used in the construction of buildings, bridges, railway stations, etc. In the year 1855 an Englishman by the name of Bessemer improved the process of purifying pig iron by blowing air in at great pressure. Over the next 25 years, a Frenchman Emile Martin then two Englishmen, Thomas and Gilchrist, introduced further improvements which allowed us to make the transition from iron to the modern period of steel.

At the beginning of the 20th century, the use of iron in construction was prohibited; in accordance with the new regulations only steel could be used. Nevertheless, to this day there exist numerous structures made of iron which are still in service. Renovation of structures built in the second half of the 19th century is to be expected. The most important question to address is whether the structural material is iron or steel. In order to answer this, a sample must be taken and laboratory tests performed in order to determine the mechanical and chemical properties of the metal. These results will enable us to define the techniques which need to be adopted, particularly in relation to welding.

Further developments in substituting coal and subsequently coke for charcoal prepared the way for industrial steel production which began in the middle of the XIXth century AD.

Even though the same principles initially developed over 100 years ago are still used in the majority of steel production, instruments and techniques have developed considerably:

The developments have resulted in:

These factors have made it possible to simplify construction thus reducing fabrication, joining and assembly costs whilst at the same time enabling improvements in aesthetic appearance.

For example in bridge construction, the main beam of a bridge made 100 years ago consisted of a riveted combination of flats and universal sections. Today, a single plate with a variable thickness permits the optimisation of the section and hence a saving in weight and manufacturing costs. In addition the maintenance of the bridge is reduced since surfaces are smooth and encourage the rapid dispersal of water.

All of these factors have made it possible to maintain competitive prices and provide the quality demanded by users.

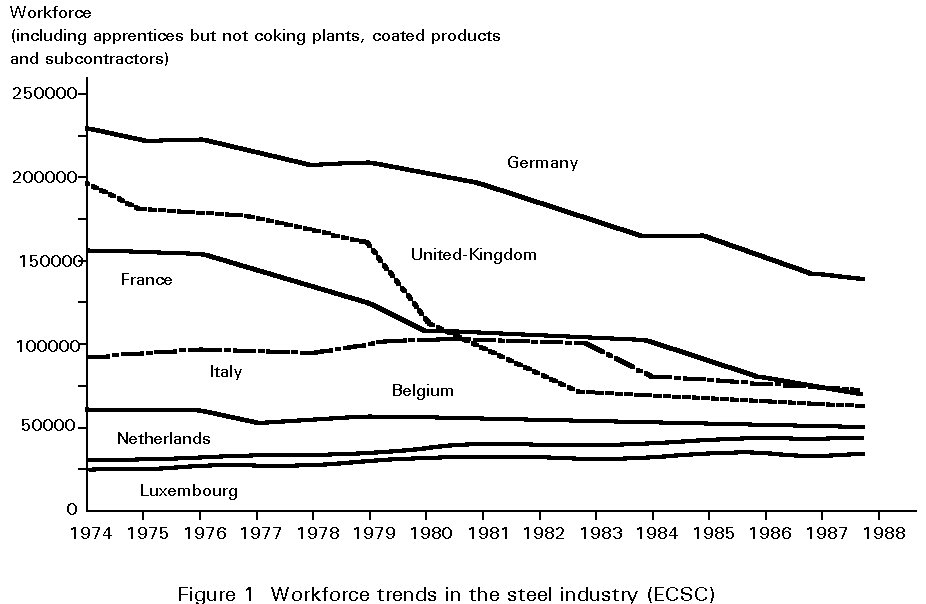

In 1989, world crude steel output was approximately 784 million tonnes.

Note: "Crude steel" refer to products which appear either in a liquid form (ready to cast) or in the form of solid ingots (obtained by liquid steel cast into a mould to be processed later on).

The world steel producers are found geographically as follows (Figure 2):

|

Far East: Japan (108 MT) - China (61 MT) - South Korea (22 MT) |

191 MT | 24,5% |

| Former USSR | 161 MT | 20,0% |

| EEC12 | 140 MT | 18,0% |

| USA | 89 MT | 11,5% |

| Other countries | 203 MT | 26,0% |

| Total | 784 MT |

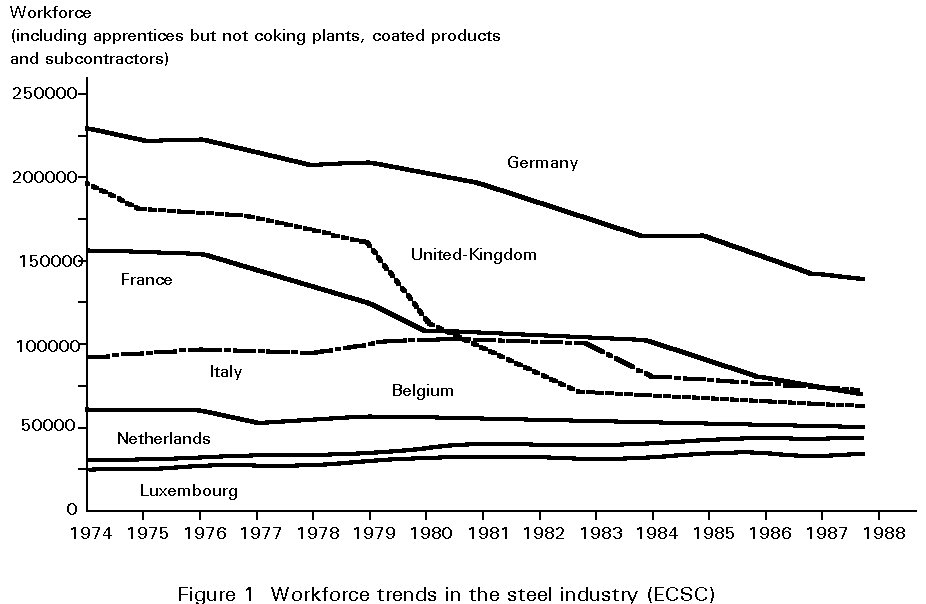

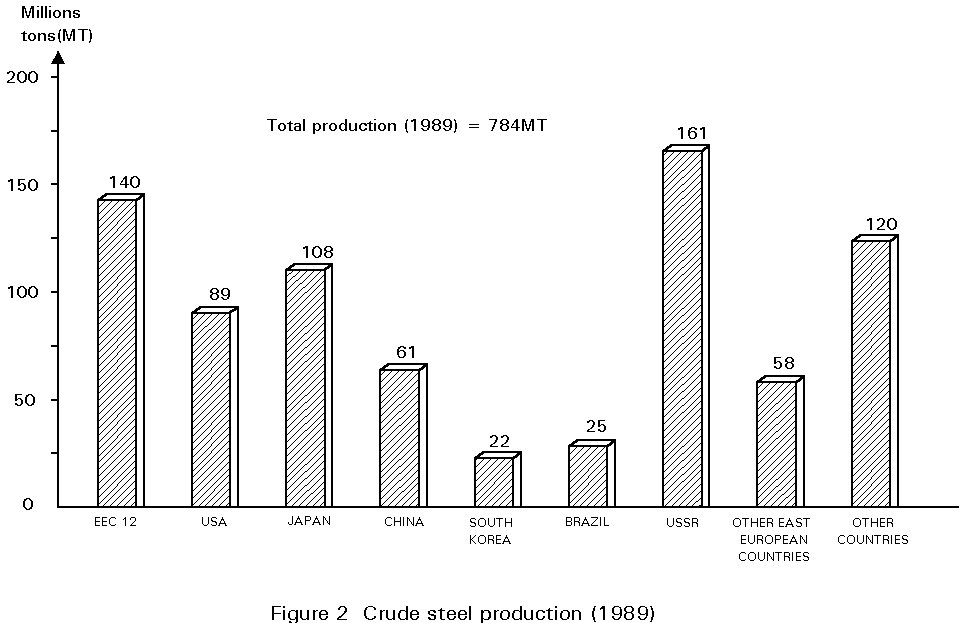

The graph of world raw steel production reflects the development of the world economy (Figure 3).

In 1988, more than a fifth of the steel produced in the world (167MT out of 780) was involved in international trade. Because of its high specific value i.e., the ratio between the price per ton and the density, steel is a product that "travels" more easily than other materials such as aluminium, wood, cement or glass. Nevertheless, most international steel trade is over short and middle distances, and seldom over long distances. Exchanges are essentially intra-community exchanges - 41 MT out of the above-mentioned 167 MT were exchanged between the different EEC countries and, on a larger scale, 83 MT between continental European countries. Moreover, 23 MT of steel were exchanged between Asia and Australasia.

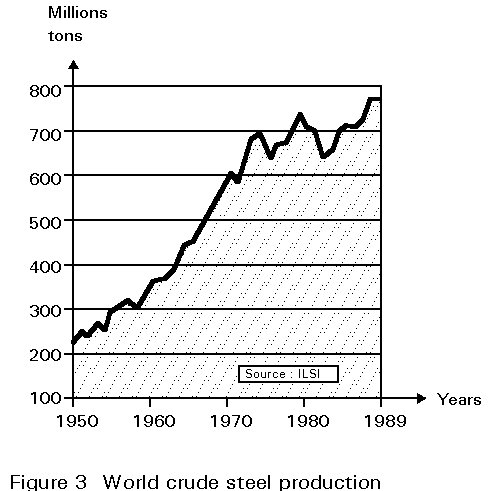

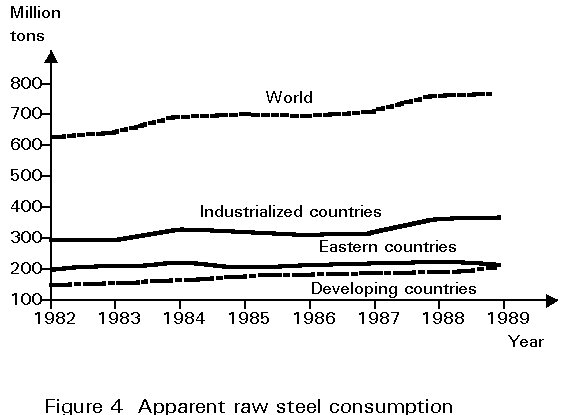

The growth of apparent raw steel consumption shows that the need for steel is rising in the world (Figure 4).

Improvements in the making of steel and its intrinsic properties have led to a decrease in its specific consumption, i.e. the weight of steel used for a specific purpose. Although Figure 4 indicates only a slow increase in raw steel consumption, greater use occurs because the improved quality of products, reduces the weight of steel in them.

Global changes in the world economy, the possible growth of steel needs, the developing areas and the arrival of "new" producers are all factors that influence the economy of the steel industry.

Certain patterns of production have gradually appeared:

The environmental nuisance created by the steel industry has been considerably reduced. Considerable investment has been made in connection with environmental factors:

The basis for industrial production of steel is pig iron, and although the fundamentals of the production method are largely unchanged, instruments and techniques of production have been greatly improved.

There are several types of steel. Depending on whether the metal will be used, for example, in building, electronics, automobile or packaging industries, it will require suitable physical, chemical and mechanical properties for that purpose. These properties are obtained through:

Iron is, as a chemical element (Fe), the main constituent of pig iron (96% iron and 3-4% carbon). It provides the basis for the refining of steel.

Iron, pig iron and steel are three manufactured products that appeared in this order in the history of materials. They represent different chemical combinations of iron and carbon. The carbon content determines the nature of very different products:

There are three steps in the steelmaking process:

| aim: | to adjust the chemical content of the steel |

| two processes: |

"integrated" steelmaking "electric" steelmaking. |

| aim: | to solidify the steel into blanks |

| two processes: |

continuous casting ingot casting. |

| aim: | to shape and size through rolling, and finish for sale. |

| two groups of products: |

long products (beams, bars, wire) flat products (plate, sheet, coil). |

Note: Not all steels are formed by rolling; they may also be forged, cast or manufactured from alloy powders.

The process is described in Lecture 2.2.

Steel products have been standardized in order to ensure a common language between producers and customers of steel products. Since the beginning of the XXth century, countries have developed their own standards defining and classifying steel products. The creation of the EEC has made it necessary to establish common standards named "European Norms" (EN).

The "Commission de Coordination et de Normalisation des Produits Sidérurgiques" COCOR, founded in 1953 to service the European Coal and Steel Community (ECSC), was commissioned to coordinate standards. Since 1965 COCOR has been placed under the authority of the European Commission and has published about 175 Euronorms. Each country is free to adopt or not, fully or partially, the Euronorms and Background Documents.

The completion of the European Single Market scheduled to occur at the end of 1992 has required the speeding up of standardization. The Commission created and financed, within COCOR, an independent technical department exclusively devoted to standardization activities: the ECISS (European Committee for Iron and Steel Standardization). ECISS, with the assistance of Technical Committees (TC), has developed documents which are submitted to COCOR for approval before being proposed to the CEN (Comite European de Normalisation) for adoption as Euronorms.

When a Euronorm (EN) is adopted by the CEN members, it must be fully applied as a national norm by all EEC Countries (even if they voted against it) and by EFTA members which voted for it. The EN, once adopted, invalidates and replaces the Euronorm and the corresponding national standard.

The EN is concerned with the standardization of the manufacture, chemical composition and mechanical characteristics of steel products. By way of illustration, consider one aspect of these norms, the way steels are designated.

The specification of steel quality is essentially composed of:

Example: A hot-rolled non-alloy structural steel (for use in the manufacture of welded or assembled structural elements to be used at ambient temperatures) is designated:

EN 10 025 S355

The designation may be followed by symbols concerning:

× the weldability and guaranteed values of impact energy (B);

× the deoxidation method used, if applicable (FU);

× the steel's suitability for a particular application, if applicable (KP);

× whether the steel is delivered in an effectively normalised condition (N).

The range of symbols is detailed, for this example, in the text of EN 10 025.

The relevant Euronorms and current national equivalents are shown in Table 1.

Table 1 Corresponding Table of Euronorms, ISO Standards and National Standards for EC Countries

|

European Standard EH |

Euronorm (I) |

ISO Standard |

Germany DIN |

Belgium NBN (2) |

Denmark DS |

Spain UNE (3) |

France NF |

Greece |

Italy UNI |

Ireland |

Luxembourg |

Netherlands NEN |

Portugal NP |

UK BS (4) |

|

|

17-1970 |

8457 TI |

59110 |

= 524 |

|

38 089 |

A 45-051 |

|

5598 |

|

|

EU 17 |

= 330 |

|

|

|

18-1979 |

377 |

50125 |

A 03-001 |

|

36 300 38 400 |

A 03-111 |

|

UNI-EU 18 |

|

|

EU 18 |

2451 |

4360 |

|

|

19-1957 |

657/8 |

1025 T5 |

533 |

|

38 526 |

A 45-205 |

|

5398 |

|

|

EU 19 |

2116 |

|

|

|

21-1978 |

404 |

17010 500-49 |

A 02-001 |

|

38 007 |

A 03-115 |

|

UNI-EU 21 |

|

|

EU 21 |

2149 |

|

|

|

22-1970 |

783 |

50145 |

A 11-201 |

|

7 223 |

A 03-351 |

|

3918 |

|

|

EU 22 |

|

3688/1 |

|

|

23-1971 |

642 |

50191 |

A 11-181 |

|

7 279 |

A 04-303 |

|

3150 |

|

|

|

|

4437 |

|

|

24-1962 |

DP 657/10 |

1025 T1 1028 |

632-01 |

|

38 521 36 522 |

A 45-210 |

|

5879 5680 |

|

|

EU 24 |

|

4 |

|

10025 |

(25-1986) |

630-1052 4995 |

17100 |

A 21-101 |

|

38 080 |

A 35-501 |

|

7070 |

|

|

EU 25 |

1729 |

/ 4360 |

|

|

27-1974 |

DIR 4949 |

|

147 |

|

38 009 |

A 02-005 |

|

UNI-EU 27 |

|

|

EU 27 |

1818 |

|

|

|

28-1985 |

883/1 2604/4 |

17155 |

/ 829 / 830 |

|

38 087/1 |

A 38-205 A 38-208 |

|

7070 |

|

|

EU 28 |

|

= 1501/1-2 |

|

|

29-1981 |

7452 |

1543 |

= A 43-101 |

|

38 559 |

A 48-503 A 46-505 |

|

UNI-EU 29 |

|

|

EU 29 |

|

1501/1 /4360 |

|

|

30-1969 |

|

17100 (= EU 25 = EU 30) |

|

|

|

A 33-101 |

|

3063 |

|

|

EU 30 |

|

|

|

|

31-1969 |

|

|

|

|

|

A 43-301 |

|

7063 |

|

|

EU 31 |

|

/ 970/1 |

|

|

34-1962 |

657/13 |

1025 T2 T3 et T4 |

= 632-02 |

|

36 527 36 528 36 529 |

A 45-211 |

|

5397 |

|

|

EU 34 |

2117 |

4 |

|

|

36-1983 |

437 |

EU |

/ 271 |

|

7 014 |

A 06-301 |

|

UNI-ISO 437 |

|

|

|

|

6200 5381 |

In construction, the penetration of steel in civil engineering and building activities is very variable across the regions of the world. In 1988 steel consumption in three major regions of the world was as shown in Table 2.

Table 2 Steel consumption in major regions

|

(Kt) |

Kg/inhabitant |

|

|

JAPAN USA WESTERN EUROPE |

9050/10400(1) 5200 5700/6200 |

74/85 21 17/18 |

(1) with or without "composite construction"

For each type of work, these consumptions are spread across different types of construction as shown in Table 3.

Table 3 Steel consumption by type of construction

|

(% tonnages) |

JAPAN |

USA |

EUROPE |

|

housing industrial other buildings pylons bridges and hydraulic engineering |

21 34 34 3 8 |

4 33 45 5 13 |

2 58 31 5 4 |

|

TOTAL |

100 |

100 |

100 |

Table 3 shows, for all constructional steelwork, the particular importance of:

There are marked differences between countries in the consumption of constructional steelwork, for example in Europe in 1988 (Table 4).

Table 4 Consumption of constructional steelwork (1988)

|

(Kt) |

Kg/inhabitant |

|

|

United Kingdom West Germany France Italy Spain Netherlands Luxembourg Sweden Finland Switzerland Portugal Austria Norway Denmark Greece Ireland Belgium |

1227 1045 683 570 500 727 100 94 185 89 100 94 80 73 50 60 195 |

22 16 15 11 13 31 28 17 25 18 10 11 20 11 5 17 28 |

|

estimated TOTAL |

5867 |

17 |

Source: European Convention for Constructional Steelwork

Several "small" countries have a very high constructional steelwork consumption/ inhabitant (Netherlands, Belgium, Luxembourg, Finland, Norway). In the United Kingdom, which is the European country with the largest constructional steelwork industry, the use of steelwork/inhabitant is higher than in any other major country.

Steel product tonnages of all construction steelwork are globally distributed as follows:

Steel products:

Hot rolled sections H, I, U, L about 60%

Plates about 20%

First processing products:

Coated sheets,

Cold rolled sections, pipes about 20%.