ESDEP WG 1A

STEEL CONSTRUCTION:

ECONOMIC & COMMERCIAL FACTORS

To inspire students with an enthusiasm for steel construction. To identify the advantages of steel for construction in Europe, emphasising its future potential and the rewarding challenge it offers to able students. To introduce ESDEP as a response to this potential.

None

Lecture 1A.2: Steelmaking and Steel Products

Lecture 1A.3: Introduction to Structural Steel Costs

Lecture 1A.4: The European Building Market

Steel has been produced for about 100 years. It is a modern material with an exciting future.

The advantages of steel are described together with recent developments which have enhanced them, i.e. improvements in manufacture, enhanced range of properties, improvements in fabrication and speed of construction, adaptability, consistent quality, lightness, stiffness and strength.

The future development of uses of steel, the associated training needs and the role of ESDEP in meeting those needs are discussed.

Steel was first produced in the Middle Ages, but it was not until just over a century ago that it was used for structural engineering.

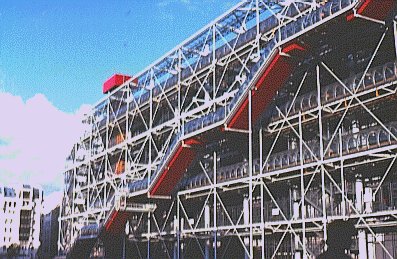

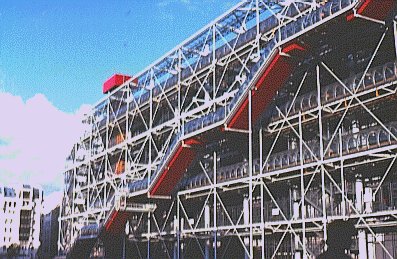

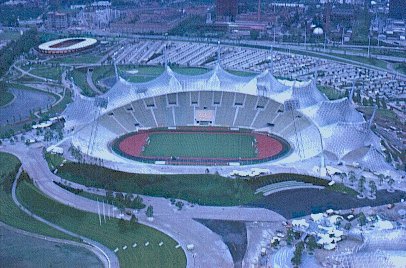

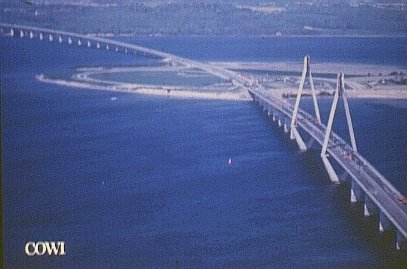

Today, many remarkable structures demonstrate the possibilities of this well developed material in their clear and transparent appearance, Slides 1 - 5.

Slide 1 : Centre Pompidou, Paris, France

Slide 2

Slide 3 : Olympic Stadium, Munich, Germany

Slide 4 : Faro Bridge, Denmark

Slide 5 : North Sea Oil Platform

The strength-to-volume ratio, the wide range of possible applications, the availability of many standardised parts, the reliability of the material and the ability to give shape to nearly all architectural wishes are some of the reasons to choose this material for the main structure and for other elements of a building or other construction.

Safe and strong steel structures are assured by well-educated designers with a Quality Assured and Quality Controlled production. A long life with a small amount of maintenance can be guaranteed by using well designed details, a high level of pre-production in modern well-equipped shops with skilled employees and modern corrosion-resistant systems.

Many of the inherent advantages of steel have been considerably enhanced by the vigour with which the steel construction industry has improved its performance in an increasingly competitive world.

Early steels were manufactured by a range of processes which produced a material of uncertain composition and variable properties. Today almost all structural steel is produced by the BOS (Basic Oxygen Steelmaking) process together with a modern purification process which produces a fine grained, weldable material of consistent strength and toughness.

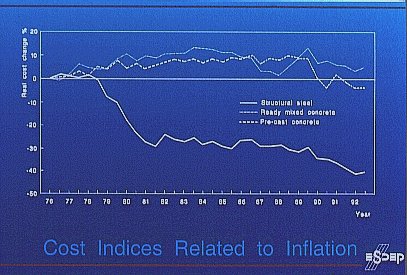

Whilst methods of steel production have improved since the first introduction of the material, the rate of improvement has been most dramatic in the last decade or so. Since the mid-1970's steel productivity has increased from 60-100 kg/man hour (depending on producer) to over 250 kg/man hour for most modern plants. This improvement has had a significant effect on relative material costs, Slide 6.

Slide 6 : Relative material costs showing the relative change in prices between steel and concrete in recent years

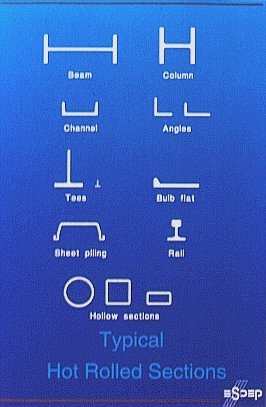

Improvements in basic production have been matched by investment in better rolling mills. The latest hot rolling mill can produce sections to a wider variety of shapes with close tolerances, good surface finish and consistent, homogeneous composition. Slide 7 gives an indication of the range of sections that are produced. Heat treatments in-line permit the greater control and enhancement of mechanical properties. Cold rolling can be used to produce thin gauge strip material which can subsequently be formed into a wide range of shapes, Slide 8.

Slide 7 : Range of typical standard hot-rolled sections manufactured by the steelmaking industry

Slide 8 : Range of typical cold-rolled profiles manufactured from thin galvanised sheet

This revolution in manufacturing techniques has been accompanied by, and has probably been possible because of, a major restructuring of the entire industry. It is worth recalling that the European Coal and Steel Community (one of the founding components of the European Community) was established in 1952 to ensure the restructuring of these crucial industries after World War 2. It has been a difficult and painful process for both traditional industries but a lean, fit and modern steel industry has finally emerged.

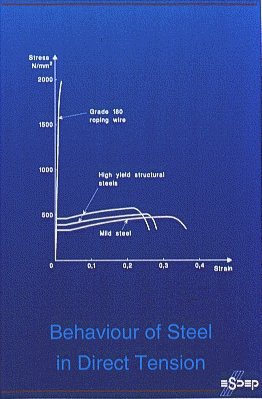

While cheap, good quality mild steel remains the backbone of the industry, it is now complemented by a wider range of commercially available structural steels, Slide 9. High yield steel has increased in popularity as designers strive for more cost effective structures. Where necessary, thermo-mechanically controlled rolled steels can be specified. Slide 9 also shows the mechanical properties that can be obtained with special steels, in this case a very high strength wire.

Slide 9 : Mechanical properties for a range of steels showing the wide range of characteristics which different steels exhibit

Improvements in mechanical properties are best typified by a simple example. The Eiffel Tower was undoubtedly an engineering triumph when it was completed in 1888. Making the best use of the available materials, it contains around 7000 tonnes of iron. A redesign today would require just 2000 tonnes.

The breadth of steels also encompasses corrosion resistance. Weather resistant steels that can, in appropriate circumstances, be left unpainted throughout the life of the structure are now used for many bridges, Slide 10. Stainless steels are available in an almost bewildering range of compositions. Appropriate choice of chemistry and finish produces a durable and attractive structure, Slide 11. Coated steel products are very widely used for cladding, Slides 12 and 13.

Slide 10 : Footbridge - York University, UK

Slide 11 : Opera de la Bastille, Paris, France (1991).

Slide 12 : Use of cold rolled steel for cladding at Revigny, France

Slide 13 : Use of cold rolled steel for cladding: (Entrepot de la Societe Calberson, France).

Design in steel used to be regarded as a 'black art' where one only reached a level of competence after 20 years of hardwon experience. Whilst, of course, experience is still very important, the designer is now much better supported and is able to be more accurate. Computers have made routine, levels of analysis that would otherwise have taken much manual calculation. Codes of practice have become more comprehensive. The advent of limit state design concentrates the designer's mind on the most important aspects of a particular design. The Eurocodes [1 - 4] are the culmination of many years' hard work, drawing together the best information on steel and composite design.

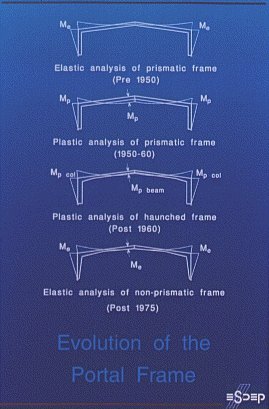

Two example illustrate the refinements in structural form that have been achieved by the improvements in understanding of structural behaviour, analysis and design. The portal frame, the subject of much research from 1950 to the present day, is an elegant, minimalist structure, see Slide 14. Its inherent efficiency of shape (its centreline closely follows the thrust line that would be associated with an axial equilibrium path, thus minimising bending moments) is enhanced by modern plastic or elastic design. Plastic design permits redistribution of the moments so that the bending moment envelope is the closest possible fit to the envelopes of uniform strength associated with prismatic sections; a haunch is used to resist the peak moment at the eaves. Elastic analysis and modern methods of fabrication permit the construction of a frame whose varying strength distribution is a close fit to the elastic bending moment envelope.

Slide 14 : Evolution of portal frame design

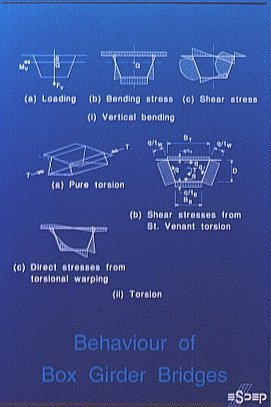

The second example is the modern box girder bridge, see Slides 15 and 16. This elegant form of construction permits the use of wide flanges, thus reducing structural depth. The inherent torsional stiffness of the closed section is used to distribute the effects of eccentric loading over the full width of the section, thus reducing maximum bending stresses. Internal diaphragms serve both to jig the box during fabrication and to resist distortion of the cross-section which could reduce the torsional resistance of the closed section.

Slide 15 : Box girder bridge near Nijmegen, Netherlands

Slide 16 : Behaviour of box girder bridges

In parallel with the improved efficiency of steel production, there have been significant increases in the productivity of the steel fabrication industry, with roughly a doubling in output per man between 1980 and 1990. The introduction of numerically controlled machine tools has not only greatly reduced the time in both preparing and handling the material but has also made an important contribution to achieving higher quality. The shot blasting of steel sections and the process of painting can now be carried out automatically, while sawing and drilling operations have also been automated. In the most modern plants, conveyor systems are available which transfer material from machine to machine.

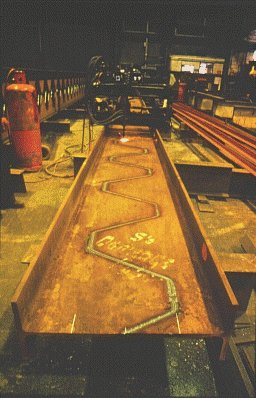

A good example of a piece of modern fabrication equipment is the numerically controlled plant for flame cutting castellated sections. Such equipment offers substantial improvements in quality and productivity compared to traditional equipment, see Slide 17.

Slide 17 : Numerically controlled cutting of castellated beams

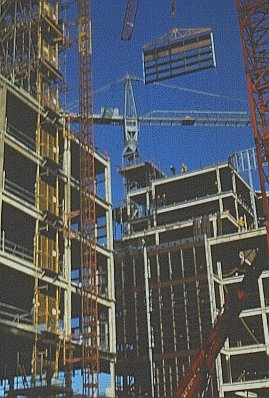

There is increasing pressure on all civil and structural engineering projects to reduce the periods of execution. Nowhere has this had a more dramatic impact on methods of execution than in the streamlining and simplification of a modern composite building.

Much execution is now by management contract in which the conventionally sequential activities of design, substructures execution, superstructure execution, envelope execution and finishing are overlapped to reduce the overall contract period. The contractor becomes a member of the design team at an early stage. In many cases the client becomes involved in the buildability of the project which is divided into self-contained work packages.

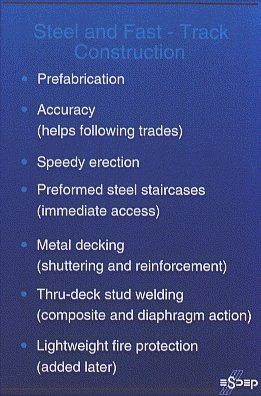

Structural steel - fast, accurate, prefabricated - lends itself naturally to fast track execution. Key elements are metal deck for shuttering and reinforcement; through-deck stud welding for composite and diaphragm action and lightweight fire protection, Slide 18.

Slide 18 : Structural steel in fast track construction

Metal deck is easily hoisted in bundles and laid out by hand (Slide 19). Edge trims are available to level concrete and prevent over-run (Slide 20). The shear studs which provide the key between beam, deck and concrete can be placed by a single operative at 1000 per day (Slide 21).

Slide 19 : Metal decking ready to be laid by hand

Slide 20 : Edge trims for metal deck floor construction

Slide 21 : Fixing shear studs

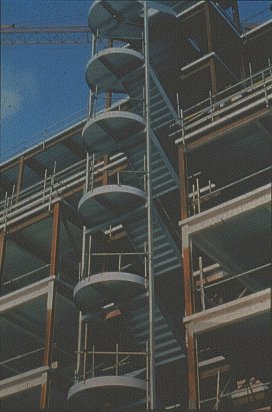

Concrete is placed by pumping (Slide 22). Services are easily fixed to the underside of the decking (Slide 23). Prefabricated stairs can be transported by crane and placed in position to give rapid and safe access for construction workers (Slide 24). Cladding units - pre-cast granite faced or curtain walling -can be lifted straight from the lorry and into position to avoid site storage (Slide 25).

Slide 22 : Concrete being placed by pumping

Slide 23 : Services fixed to underside of decking

Slide 24 : Pre-fabricated stairs

Slide 25 : Curtain walling

Steel frames with both metal deck and pre-cast concrete planks permit sequential execution with following trades able to proceed in safety and with protection from the weather.

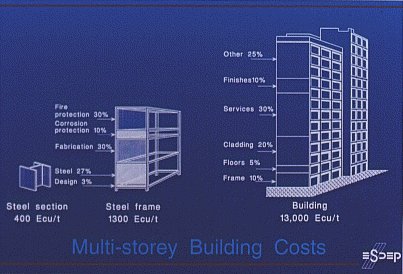

Traditionally, the greatest disincentives to the use of steel for multi-storey frames were the additional costs and time for fire protection (Slide 26). However, the use of new, lower-cost, lightweight board and spray systems have now largely replaced in-situ concrete encasement. Fire protection costs have thereby been halved and the implications on execution programmes reduced substantially. (The programme savings outlined above include the fire protection systems).

Slide 26 : Breakdown of steelwork construction costs

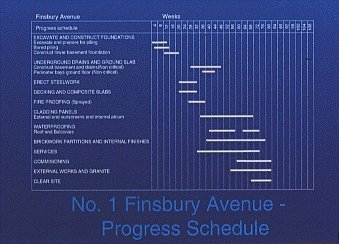

In many cases the benefits of faster speed of execution can be translated into substantial financial savings for the client. These savings are particularly significant in situations where he has made substantial initial investment in acquiring the site. Slide 27 shows the execution programme achieved at the Finsbury Avenue Project in London. This programme represented a 40 week saving over conventional construction in in-situ concrete. While, for a typical building the costs of the two solutions are similar, at around 900 ecu/m2 at 1990 prices, studies of London development costs suggest time-related savings of up to 7 mecu per week (for the whole building) for earlier completion in a buoyant letting market, potentially dwarfing the total cost of the structure.

Slide 27 : Construction programme for No. 1 Finsbury Avenue, London (1985)

Steel structures are generally lighter than those in other materials. In almost all cases this lower weight leads to lower costs for foundations particularly for sites with poor ground. Smaller columns increase effective floor utilisation and, where longer spans are required, the cost savings between steel and other forms of construction increase considerably. For large column grids in buildings, steel is the only feasible solution.

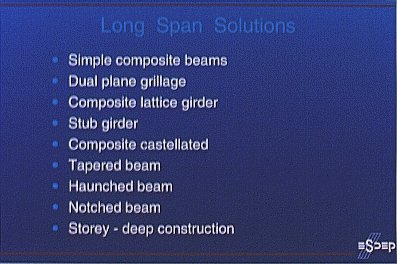

For multi-storey commercial offices a number of new design approaches are being introduced to achieve clear spans of 12-18m or more (slides 28 and 29) . These approaches include composite universal beam and lattice girder arrangements; parallel beam approaches; tapered, haunched and notched beam and storey deep construction, Slide 30. These schemes can increase spans in office buildings with only a small increase, in many cases less than 15%, in structural costs. Since the structural cost is only a small proportion (< 20%) of the total development cost, clear span offices can be achieved for less than 3% of total development cost. This cost is a very small premium to pay for the increased flexibility in usage that results. Office activities are changing rapidly, following the high rate of change of information technology; one can only speculate on the requirements 30 years from now, well within the life of the structure. Clear, column-free space offers the best opportunity of being able to adapt a building to these changing needs.

Slide 28 : Long span floor systems for office buildings - alternative solutions

Slide 29 : Long span floor systems for office buildings

Slide 30 : Long span floor systems for office buildings

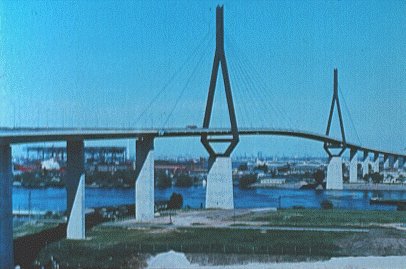

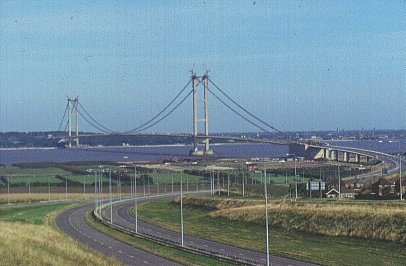

For bridges, the strength and toughness of steel have led to the elegant solution of cable stayed and suspension bridges and the tight tracery of modern truss bridges, Slides 31-33. Similar design concepts have led to the development of striking structural solutions for long span roofs.

Slide 31 : Kohlbrand Bridge, Hamburg, Germany

Slide 32 : Humber Suspension Bridge, UK (1982)

Slide 33 : Tonegawa Bridge, Saitama Prefecture, Japan

In other contexts triangulated structures have been refined and lightened to the extent that they become sculptures, Slide 34.

Slide 34 : Telecommunications mast, Barcelona, Spain

Structural steel provides maximum adaptability for changes in building use, because structural alterations can be accommodated with relative ease. Where additional members are required, connections can be made to the existing frame with minimum disturbance and cost. It is for this reason that steel frames have been so popular with leading retail and industrial groups.

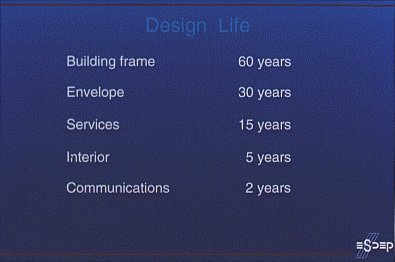

The importance of adaptability in use is also demonstrated by considering the widely differing life spans of the components of a modern office building, Slide 35. The benefits of longer spans in this context have already been discussed in the previous Section. It is likely that some part of the long-life structure is going to require modification to accommodate some radical change in information systems or services.

Slide 35 : Differing life spans of building components

The attribute of adaptability is of particular importance in refurbishment contracts, whether it is a case of strengthening existing structures or complete re-construction behind retained facades (Slides 36 and 37). Steel is delivered to site pre-fabricated; it does not need propping once in position nor does it suffer from shrinkage or creep. It can therefore take load immediately. When it is chosen for the structure behind a retained facade, the frame can be inserted through pockets cut in the structure. Modern techniques like metal deck floors can be used with advantage in accommodating irregular floor plans and extensive services can be installed, just as in a new building.

Slide 36 : Strengthening existing concrete floors

Slide 37 : Reconstruction behind retained facades

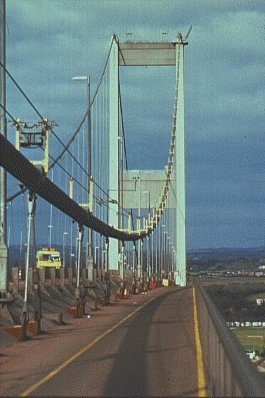

Steel's adaptability can also be put to good use in bridges. The main towers of the Severn suspension bridge, Slide 38, were strengthened to absorb a doubling of traffic loading since the structure was initially designed 40 years ago.

Slide 38 : The Severn Bridge after completion of major strengthening

Employment patterns in construction have recently changed considerably. Most site work is now carried out by small, labour-only subcontractors. These companies have little long-term involvement in the construction sector and are too informal to make any investment in training. The striving for further economy has reduced the overall level of site supervision.

In this environment it is difficult to maintain the quality of on-site construction. However, a steel frame is a factory made, precise product, produced by a stable, well-trained workforce. Only the erection of pre-fabricated members is left for the site - a process which is easily controlled.

The previous section has drawn attention to the inherent advantages of steel and the way in which recent developments are strengthening those advantages. It is remarkable that a material that is 100 years old should still be capable of such worthwhile development. It is more remarkable still that the rate of development in many sectors appears to be increasing. Development is in response to the greater rate of change of society's demands of its built environment and the greater willingness of an increasingly competitive commercial industry to respond to the needs of society and its customers.

It is possible to speculate on some of the directions that further development might take.

It is clear from the foregoing that the demands on engineers' skills and knowledge are going to increase for the foreseeable future. Within the context of an increasing rate of change, society will demand an increasing standard from its built environment. Both initial technical education and in-career training are going to become even more important than they are today.

The greatest training resources for steel in Europe are in its widely distributed network of technical skills. A particular strength of the steel construction industry is the existence of an infrastructure of specialist personnel who have learnt to work together through the media of both the ECCS technical committees and the drafting committees of Eurocode 3 and Eurocode 4.

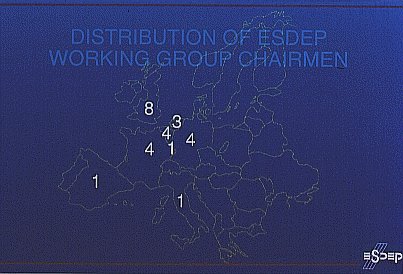

ESDEP, the European Steel Design Education Programme, was established in 1988 to draw on both resources to prepare a comprehensive set of teaching aids on steel design and construction. It comprises nineteen working groups with an appropriate supporting network of steering committees. Over 200 specialists from all countries of the European Community and the European Free Trade Association have contributed to the project, Slides 39 and 40 summarise how the project was managed and the distribution of contributors and working groups. The projects was sponsored by the European Commission and the steel industry from every country in both the EC and EFTA. Steelwork designers and constructors who will benefit from the improved quality and performance of the industry, have much cause for gratitude for their farsightedness.

Slide 39 : ESDEP: Distribution of working groups throughout Europe

Slide 40 : ESDEP: Distribution of contractors throughout Europe

[1] Eurocode 1: "Basis of Design and Actions on Structures", CEN (in preparation)

[2] Eurocode 3: "Design of Steel Structures": ENV 1993-1-1: Part 1.1: General Rules and Rules for Buildings, CEN Brussels, 1992.

[3] Eurocode 4: "Design of Composite Steel and Concrete Structures": ENV 1994-1-1: Part 1: General Rules and Rules for Buildings, CEN (in press).

[4] Eurocode 8: "Earthquake Resistant Design of Structures" CEN (in preparation)