ESDEP WG 10

COMPOSITE CONSTRUCTION

To complement the other lectures, which cover the use of composite beams and girders in buildings, with special recommendations regarding bridge design and construction; and to introduce the conceptual and technical process for the design of composite bridges.

Lecture 10.1: Composite Construction - General

Lecture 10.2: Behaviour of Beams

Lecture 10.3: Single Span Beams

Lectures 10.4: Continuous Beams

Lectures 10.5: Design for Serviceability

Lectures 10.6: Shear Connection

The advantages of composite bridges are outlined with emphasis on the use of this bridge type for normal spans. The different types of cross-sections used are introduced, concentrating mainly on box and plate girders. Attention is drawn to the many different construction and erection stages with different "active" cross-sections and structural systems.

Composite bridge construction has experienced considerable development since the first solutions in the 1950's using simple parallel beam grids over short spans (from 20 to 25 metres), to its present usage in large framed or cable stayed bridges, or in very important truss girders designed to meet the severe functional requirements of high speed trains. It is now commonly used for medium and large works, and also in cases of minor spans competing with prefabricated prestress concrete systems, where, for example, problems of quick erection or slenderness arise.

It is not possible, in this general lecture, to describe or to catalogue the complete range of actual solutions that composite construction offers for bridges. Nor is it possible to outline the general problems of details, construction procedures, choices of analysis, etc. The lecture therefore concentrates on emphasising the advantages that the composite structure offers, dealing mainly with the systems and construction processes for medium span bridges. The lecture is completed with brief references to other methods that can be useful in more important cases that require wider specialization and experience before they can be applied.

First an understanding of the nature of the inherent aspects of the bending of composite systems and the rheological interaction of the deck's construction materials is required. Starting from certain fundamental global considerations, an understanding of the phenomena that principally determine the functional performance, structural behaviour and execution problems of composite bridges can then be reached.

Therefore, the lecture analyses questions related to:

Fabrication and erection methods have a big influence on the detailed design of the steel structure. The supporting steel members must be designed so that they do not interfere with the placing of the concrete slab.

The following general observations can be made concerning the principal types of composite bridge decks:

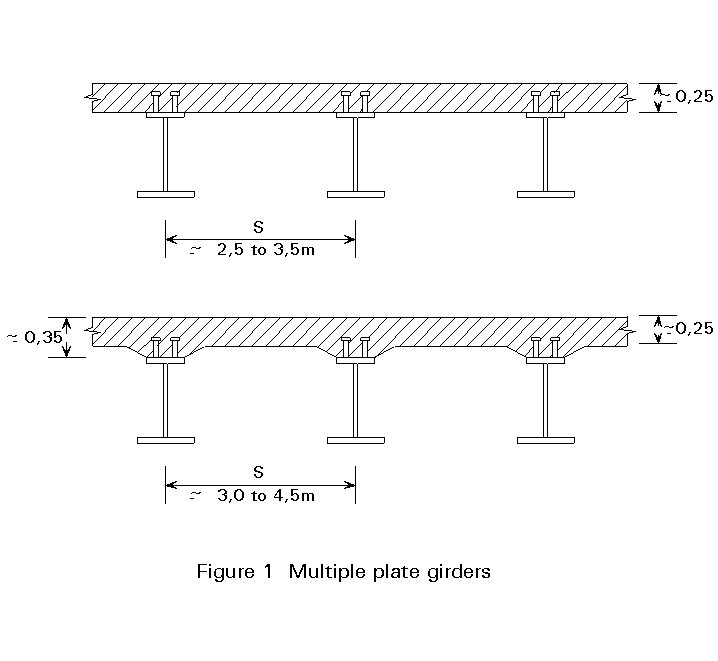

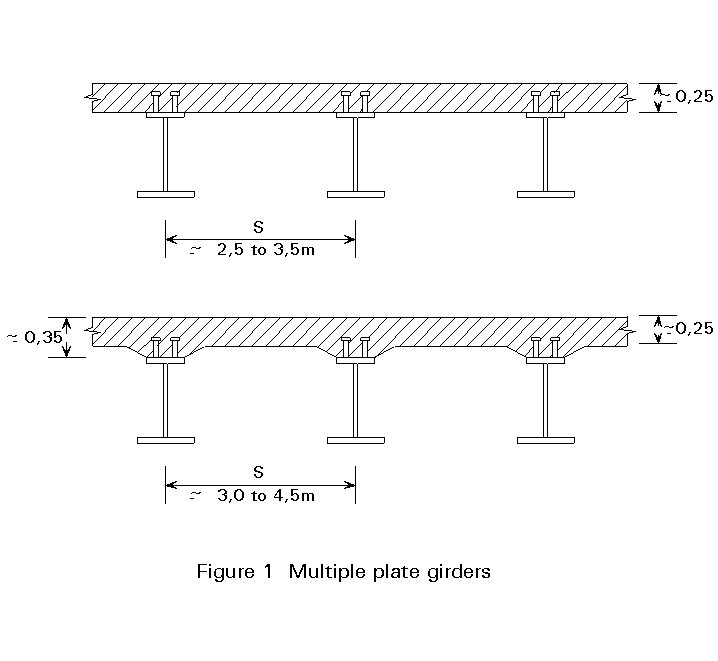

For short spans, 25 to 45m approximately, solutions using multiple plate girders without any kind of transverse bracing are preferred with the concrete deck slab performing the total function of transverse distribution and stability (Figure 1). The number of beams should be the least compatible with the transverse distribution capability of the concrete slab.

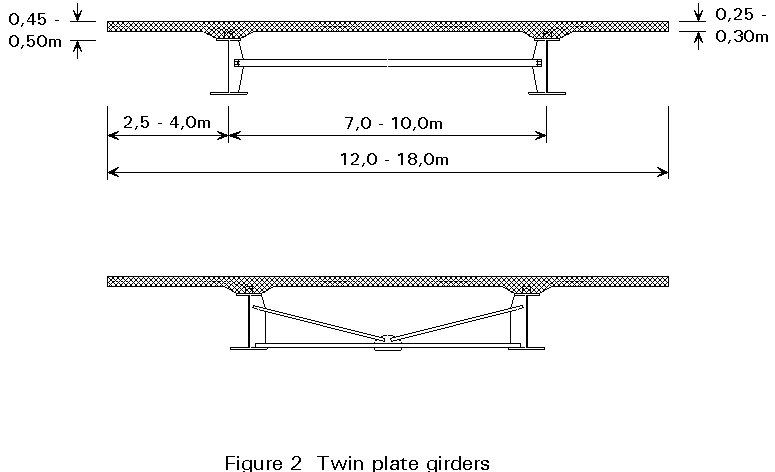

Twin plate girders with haunched slab can be a very attractive solution for narrow bridges (Figure 2).

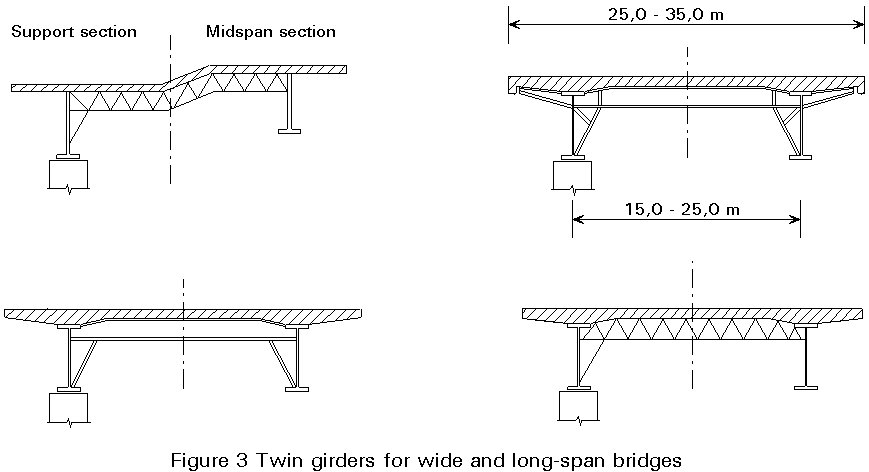

For longer spans (50 to 100m) the system of widely spaced twin girders (Figure 3) joined with transverse composite beams, spaced at about 4 to 5 metres, is very suitable. Main and transverse girders can be plate girders or, in cases with very long spans or very severe deflection limits, trusses.

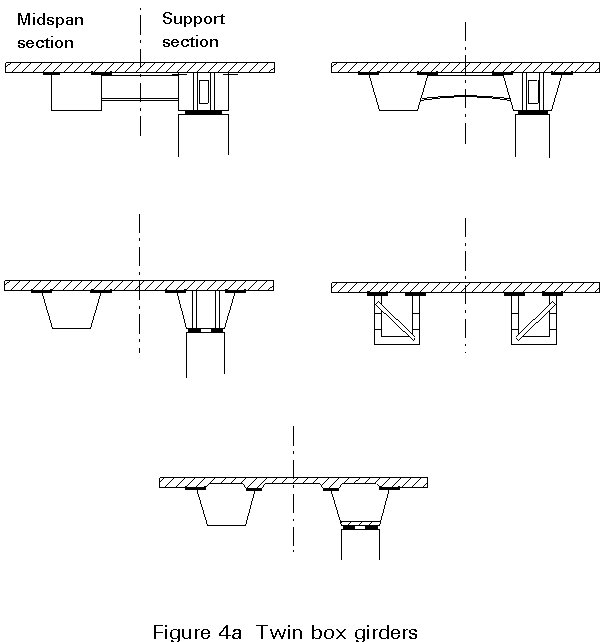

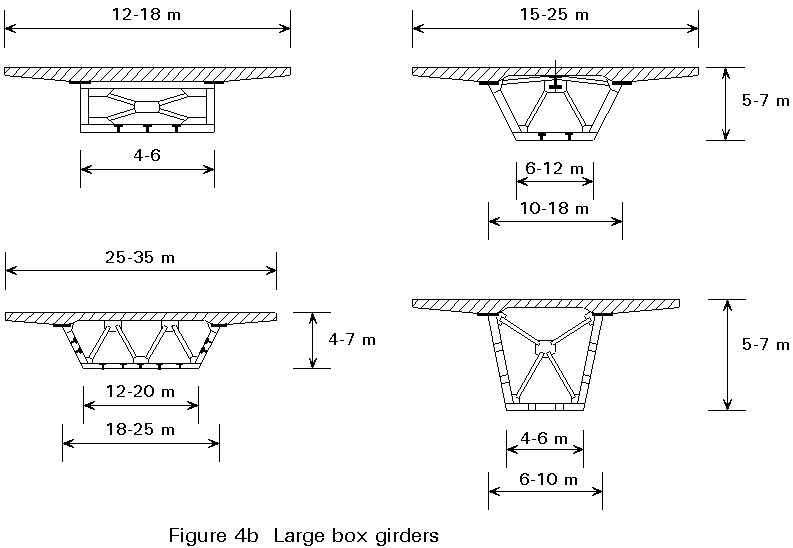

Box girders, preferably with trapezoidal semi-open cross-sections (Figures 4a-b), also provide adequate solutions for all of the above mentioned cases, especially when curvatures exist in plan. Box girders become almost obligatory if the curvatures are very sharp.

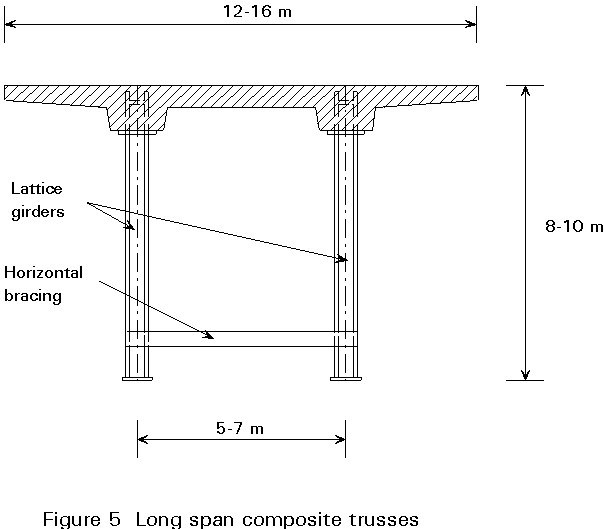

For very large railway bridges, cross-sections formed by two large composite lattice girders (Figure 5) and used with or without bottom concrete slabs, give very suitable solutions in terms of ease of construction, economy, serviceability and durability.

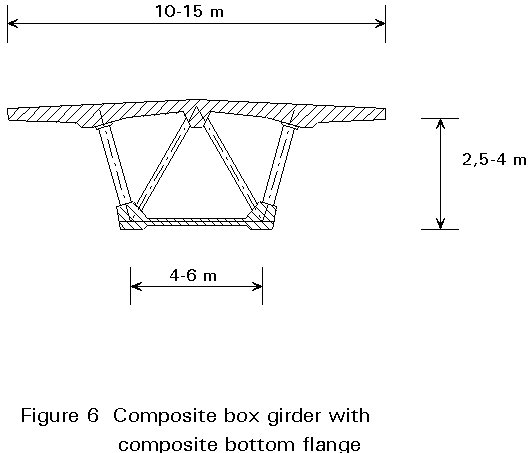

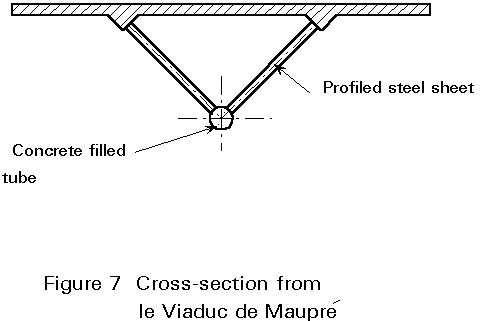

Other solutions are based on the use of lattice webs joined to top and bottom concrete slabs (Figure 6), or profiled steel sheet webs concreted to concrete filled and prestressed steel tubes (Figure 7).

By the appropriate combination of the two principal construction materials, structural steel and concrete (reinforced or prestressed), more efficient bridge construction can be achieved than is possible using the two materials independently. This advantage is gained particularly when the work specification is demanding in relation to short construction periods, functional conditions of high slenderness, the site topography, road or services complexity, or complex layouts in plan or elevation.

In particular, the use of self-supporting steel systems allows, in the same way as for steel bridge construction, the execution to proceed without shoring during the concreting of the deck slab thereby giving rapid execution even with difficult layouts, (strong curvatures in plan, complex transverse sections, etc.). Later the deck slab is used as an element of great inertia and resistance, which reduces the total amount of steel required, especially in the compression zones where its use reduces the need for additional stiffening and/or bracing.

This advantage, which is clear in the sagging regions, can be extended to the hogging regions through the correct use of prestressing methods, or to a lesser extent, with longitudinal reinforcement of the concrete slab, giving partial improvement to its properties. Likewise, an intelligent additional steel-concrete combination in double composite action could extend the global application of the composite solutions, as will be explained below.

The resultant performance-structural-executional symbiosis of these two major materials improves the whole to a much greater extent than the simple juxtaposition of the two materials. The designer should carefully combine the steel and concrete in proportions that optimise the bridge performance in all the above-mentioned respects.

Essentially the principal advantages of composite bridges in comparison with others of similar dimensions are:

In comparison with concrete systems:

In comparison with steel systems:

Irrespective of the type of bridge considered, maximum efficiency is achieved by adopting transverse cross-sections and execution processes that maximise the potential of the composite system.

This consideration in the past gave rise to the use of propped construction of the partial steel section, or systems with pre-deformation (prestressed, precambered, preflected). Alternatively, provisional continuity was provided by temporary restraint of joints in the steel section, the effect being transferred to the whole composite system after the hardening of the slab. Today, this technique is no longer necessary due to the adoption of limit state methods or non-linear elastic-plastic analysis to establish the ultimate resistance of the cross-sections, together with adequate control of serviceability and functional conditions. In this way the total benefit of all the structural materials included in the section can be achieved without complicating the process of execution, but by taking into consideration some special aspects in the design of the section.

In current practice, by including a slightly bigger top flange, a longitudinal web stiffener, and by giving the steel member a precamber of approximately L/200 in the workshop, ultimate and serviceability conditions for the non-propped steel beam can be obtained which are similar to those of the propped solution. Construction problems can thereby be reduced and/or sometimes solutions that are almost impossible to achieve in any other way are feasible.

The elastic-plastic behaviour of cross-sections, with the consequent redistribution of the internal stress pattern that allows the total usage of the materials in the ultimate state, begins earlier for the unpropped beam (gf = 1,21) than in the propped beam. In the propped case it occurs much closer to the collapse (gf=1,35), with a higher rate of transition to the plastic state.

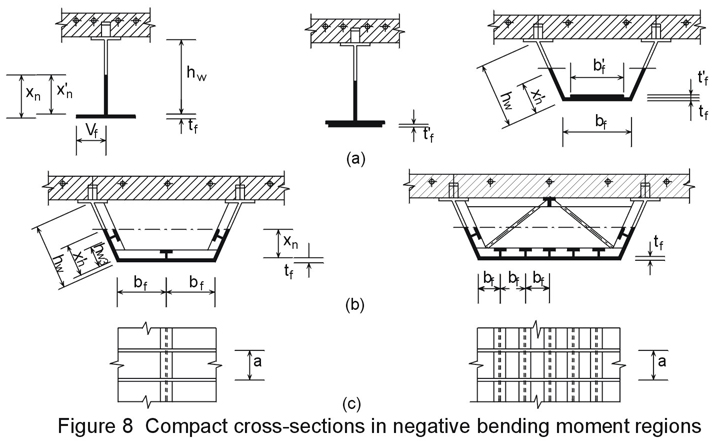

The compact character of cross-sections which allows the development of a plastic hinge can be established from the criteria defined in Eurocode 4 [1]. These criteria depend upon the steel quality and the compressed web regions. Given the variation of the neutral axis depth in the elastic or elastic-plastic ranges, the position of the neutral axis must be considered for the most unfavourable value that can occur.

In cases where, because of the large beam depth required, a compact section cannot be economically used, it is better to adopt semi-compact (Class 3) or slender (Class 4) cross-sections with elastic calculation methods. The procedures for propping and cambering, provisional restraints, preflection or prestressing, etc. could then be of interest in order to obtain the most favourable solution.

When propped construction is used, the stability of the upper flanges of steel members during the non-composite work must be carefully considered because of the minimum sizes usually adopted. This aspect is especially important when decking is placed parallel to the beams.

Negative bending moments usually imply the existence of hyperstatic systems. The redistribution over time of external forces motivated by creep and shrinkage effects should be analysed in these cases. This analysis can be approximate, if ultimate control of the structure that takes into consideration the elastic-plastic conditions at critical sections is included, because in this case all time dependent processes have little effect on the ultimate bending resistance of normally well conditioned sections.

Unlike the positive regions previously discussed, negative moment regions are highly complex analytically. They offer many design possibilities and require strong control of conditions. The ability of the designer is put to the test in order to derive the maximum benefit from the composite method of construction.

The following should be given careful consideration:

a. The top concrete deck slab, necessary for functional reasons, is in tension and so, apparently, does not contribute to the resistance of the cross-section. Indirectly, however, benefit should be taken from its presence through:

× Internal prestressing: the use, in prestressing, of high strength economically efficient steels allows the full inertial resistance of the concrete slab to be taken into account.

× Passive reinforcement: due to the bond with the concrete, reinforcement bars remain active in the total cross-section. In this case the inertia of the concrete slab is only partially used due to cracking. This behaviour creates some analytical difficulties when external forces change.

× External prestressing: it can give the optimum result by combining aspects of the previous two solutions.

b. The bending moment is normally accompanied by high shear forces that require the designer to check the moment shear interaction M-V or, M-V-T when torsion occurs. This check results in the need to increase the web thickness of the steel section and to prefer the use of even more compact sections than in the positive zones.

The compact cross-section conditions for these negative moment zones are shown in Figure 8, maintaining the dimensional limitations of the web and flange panels according to the values indicated in the Code for the positive moment zones.

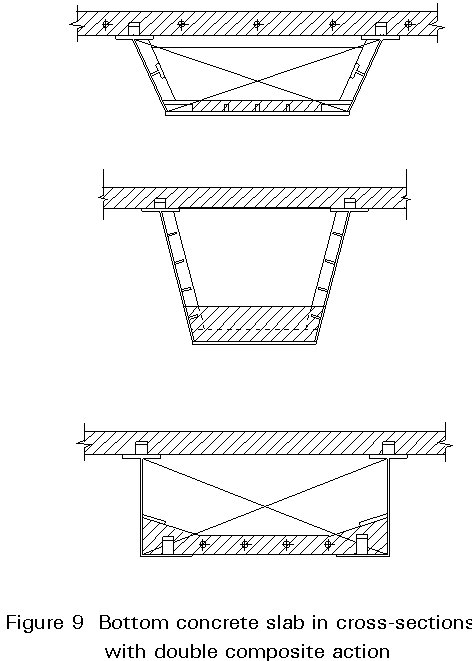

c. The possibility of using a zone of the bottom concrete slab, in double composite action should be considered. The suitability of this approach, in economic terms, depends on the type of cross-section and the agreed procedures for execution. This solution is usually a competitive option in the case of semi-open box girders, and where local slabs are located at the bottom of the steel cross-sections, (Figure 9). The concrete in these zones is situated inside the depth of the section, and so stresses can be very high, requiring an appropriate control of the rheological phenomena.

Bottom slabs introduce, in an efficient way, a very compact character to the sections, not only to the bottom plate of steel but to the web also, because the neutral axis lies closer to the bottom edge.

d. Buckling and lateral stability control

The type of cross-section and execution method play a very significant role in determining the importance of these problems and in the appropriate selection of bracing and stiffening members or systems. In these cases consideration of fatigue becomes important. The connections between the main members and the secondary bracing should be carefully considered, the objective being to restrain the cross-section simply avoiding complex internal bracing.

To be consistent for hogging regions, certain conceptual and structural aspects must be taken into account. The following are the most important aspects:

a. Concrete slab cracking

The magnitude and extent of the cracking of the deck slab in hogging moment zones is very variable and depends of the actual load in the structure. Thus the hypothesis of load superposition should not be used, but an alternative condition for every complete loading state should be analysed.

Likewise, to ignore completely the contribution of the cracked concrete (in the tension zones between cracks) to the stiffness of the structure (an effect known as tension stiffening) leads to an over estimation of the amplitude of deflections and width of cracks, and to the calculation of incorrect bending moment envelopes.

In view of this effect, a more accurate method of analysis is required which consists of the calculation of moment-curvature relationship diagrams for the cross-sections taking into account tension stiffening. Alternatively, the following formula may be applied to determine an effective value (Im) of the second moment of area of the cross-section:

![]()

where

Mr is the cracking bending moment of the cross-section.

M is the actual bending moment in the section.

Io is the second moment of area of non-cracked section.

Ir is the second moment of area of cracked section neglecting concrete in tension.

Having evaluated the effective second moment of area of the cracked regions an initial moment distribution and successive step by step analysis can be carried out. One or two steps are usually sufficient to estimate the real conditions of compatibility between bending moments and inertias in the hogging regions.

The above discussion should be considered to be equally valid for the serviceability states as for the ultimate, with factored loads adopted in the calculation. It is not valid to adopt characteristic loading and afterwards increase the effects by the gf value for the cross-section design.

Additional aspects, such as the incidence of dependent effects due to permanent loading and, pre-postcracking of the slab, introduce complexity which is usually well covered by the ultimate limit state control of cracking using the characteristic width of crack Wk=(1,64d).

b. Prestressing of the concrete deck slab

The introduction of prestressing in the concrete slab can be carried out in two different ways, each with different characteristics as follows:

× Postconnection prestressing. The prestress is usually applied at an early stage when the elastic modulus of the concrete has a low value. The design for transfer of prestressing from the concrete to the structural steel can be very important in relation to reduction of prestressing values of the concrete, and consequently reducing the cracking bending moment of resistance Mr of the cross-section.

× Preconnection prestressing. This is very efficient in the early stages, but time effects such as creep and shrinkage, tend to reduce the final effects. The prestressing is transferred to the steel members via bond and friction with the concrete slab. These problems can only be overcome by careful and costly procedures.

External prestressing solutions which allow use of controlled cracking in the concrete slab, can be applied at appropriate stages, and which affect the whole system, can represent favourable intermediate solutions.

Modern design procedures for composite bridges are tending to incorporate prestressing in the transverse direction.

c. Bending moment-shear interaction

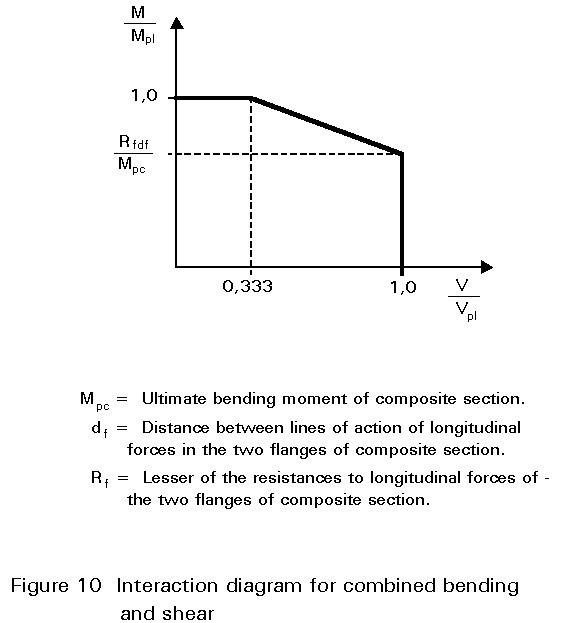

The simultaneous consideration of shear and bending can be carried out by using a simplified diagram, such as that given in Eurocode 4, Figure 10, especially when dealing with compact or semi-compact members.

d. Lateral stability of lower compression flanges

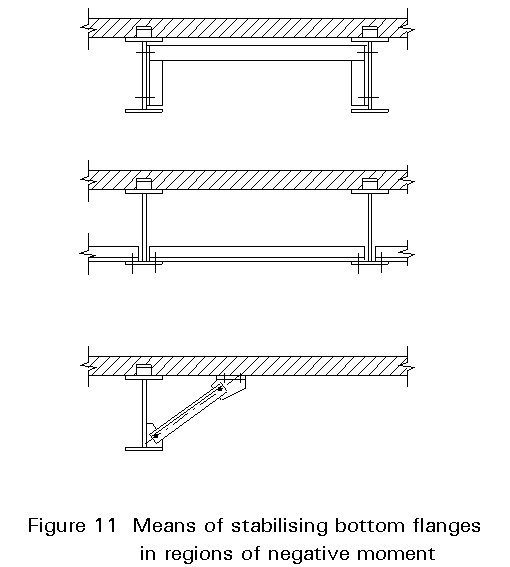

The negative moment region of simple steel members is usually unrestrained and the effective slenderness of the beam must be taken into account. Lateral restraint (such as U-frames or struts tied to the concrete slab or to another parallel beam, see Figure 11) with a resistance of 1% of the axial force in the bottom flange can provide a significant increase in resistance.

e. Bottom concrete slabs

Bottom concrete slabs can withstand higher service stresses than allowed in top concrete slabs. Higher stresses may be taken because the structural steel usually provides a confining force to the concrete and because significant stress reduction is produced with time due to creep and shrinkage effects.

The shear connection must be complete and adequate, except in very big bridges with extremely slender cross-sections designed basically for stability or stiffening conditions, and also in those cases in which the structure is analysed by elastic methods with non-propped construction of the steel members.

The term "Complete" refers to the provision of sufficient shear connectors to resist the maximum shear force that the partial cross-section can develop in the connecting plane, without considering the actual envelope of shear stresses that the structural calculations define. An "incomplete" connection would be, then, the connection that resists strictly the shear stresses that the composite system develops in the connecting surface due to construction process and loading.

The term "Adequate" means providing a connection appropriate to the resistant-deformational process assumed in the analysis of the structure. Thus, if the system is compact and requires to use elastic-plastic redistributions fully, it is essential to employ flexible or ductile connection systems, capable of adapting to the transfer of shear and slip in the connection plane. However, for slender systems designed using a totally elastic analysis, stiff connectors must be used giving minimum slip, thus ensuring that the members behave in accordance with the design assumptions.

Furthermore, the local incidence of creep and shrinkage at the ends of the beams in bridges should be estimated with some accuracy .

Likewise, the introduction of local actions, such as prestressing, also gives rise to significant shear connection forces which must be considered.

The detailed design of the steel components of a composite bridge has to take into account the process of fabrication and erection of the steel structure and the technique to be used for concreting the deck slab.

In particular, the length and weight of the fabricated steel components and the provision of welded and bolted splices on site has an influence on the design.

The cross-sections have to be built up in such a way that steel cross girders and bracings do not complicate the shuttering and placing operations for the concrete deck slab.

It is also important to ensure that some holes are provided in the steel webs to allow flexibility in fixing temporary shuttering.

Proper attention to such details at the design stage will greatly facilitate operations during execution.

[1] Eurocode 4: "Design of Composite Steel and Concrete Structures": ENV 1994-1-1: Part 1.1: General rules and rules for buildings, CEN (in press).