ESDEP WG 10

COMPOSITE CONSTRUCTION

To introduce steel-concrete composite members and construction; to explain the composite action of the two different materials and to show how the structural members are used, particularly in building construction.

Lecture 7.2: Cross-Section Classification

All subsequent lectures in Group 10.

The two complementary materials, structural steel and reinforced concrete, are introduced and it is shown how composite action is achieved in the case of composite slabs, beams and columns. The use of composite construction for buildings and bridges is outlined and illustrated by several typical examples; its main advantages are also illustrated by comparison with structures of steel and concrete used independently. Attention is drawn to the effect of this form of construction on other more general problems such as: fire resistance rating, speed of construction, flexibility and final fitting out.

The most important and most frequently encountered combination of construction materials is that of steel and concrete, with applications in multi-storey commercial buildings and factories, as well as in bridges. These materials can be used in mixed structural systems, for example concrete cores encircled by steel tubes, as well as in composite structures where members consisting of steel and concrete act together compositely.

These essentially different materials are completely compatible and complementary to each other; they have almost the same thermal expansion; they have an ideal combination of strengths with the concrete efficient in compression and the steel in tension; concrete also gives corrosion protection and thermal insulation to the steel at elevated temperatures and additionally can restrain slender steel sections from local or lateral-torsional buckling.

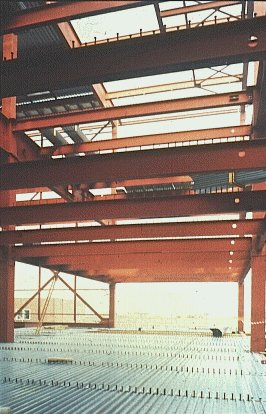

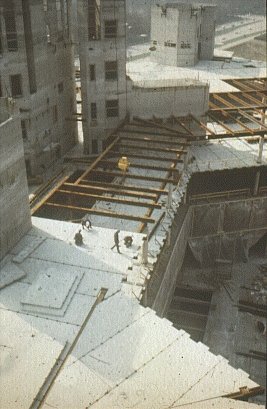

In multi-storey buildings, structural steelwork is typically used together with concrete; for example, steel beams with concrete floor slabs. The same applies to road bridges, where concrete decks are normally preferred. The extent to which the components or parts of a building structure should embody all steel construction, be constructed entirely in reinforced concrete, or be of composite construction depends on the circumstances. It is a fact, however, that engineers are increasingly designing composite and mixed building systems of structural steel and reinforced concrete to produce more efficient structures when compared to designs using either material alone. The first two slides give an impression of how and to what extent composite construction is used for multi-storey buildings: Slide 1 shows a construction site for a commercial building in London; Slide 2 shows a factory building for the car industry in Germany.

Slide 1 : Typical composite multi-storey steel-framed building during construction - a commercial building in London.

Slide 2 : Typical composite multi-storey steel-framed building during execution - a factory building for the car industry in Germany.

It should be added that the combination of concrete cores, steel frame and composite floor construction has become the standard construction method for multi-storey commercial buildings in several countries. Much progress has been made, for example in Japan, where the structural steel/reinforced concrete frame is the standard system for tall buildings. The main reason for this preference is that the sections and members shown in Slide 3 are best suited to resist repeated earthquake loadings, which require a high amount of resistance and ductility.

Slide 3 : The combination of concrete cores, steel frame and composite floor construction has become the standard method for multi-storey construction in several countries.

Building with steel and composite elements experienced a renaissance during the 1980's, resulting in a profusion of new construction concepts and structural details.

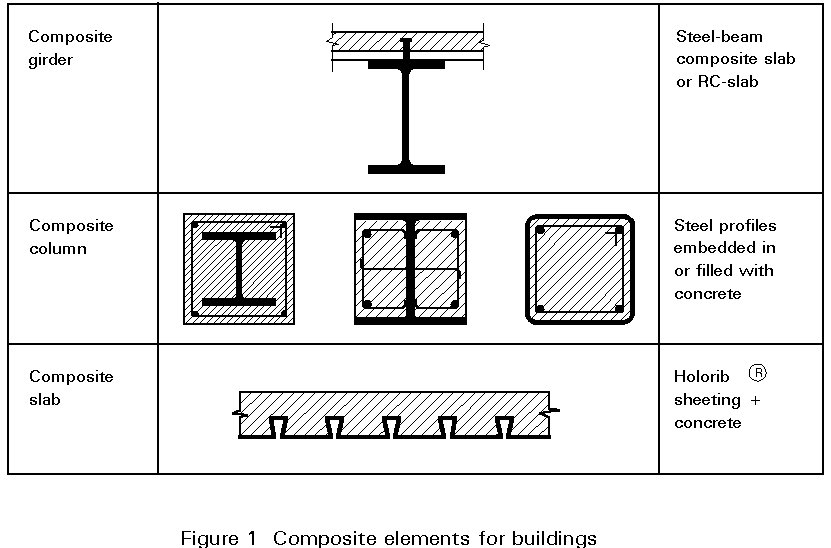

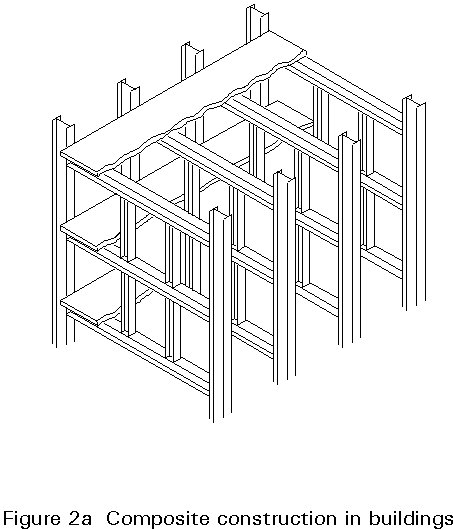

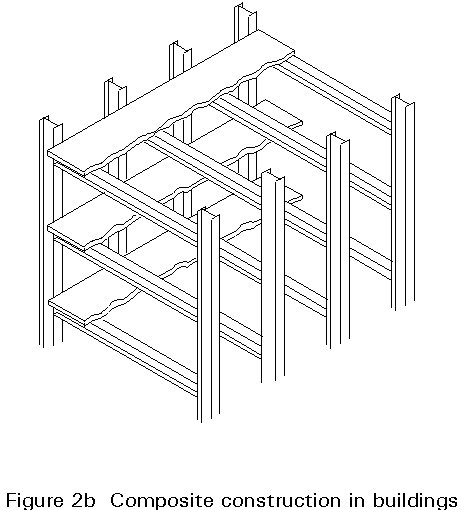

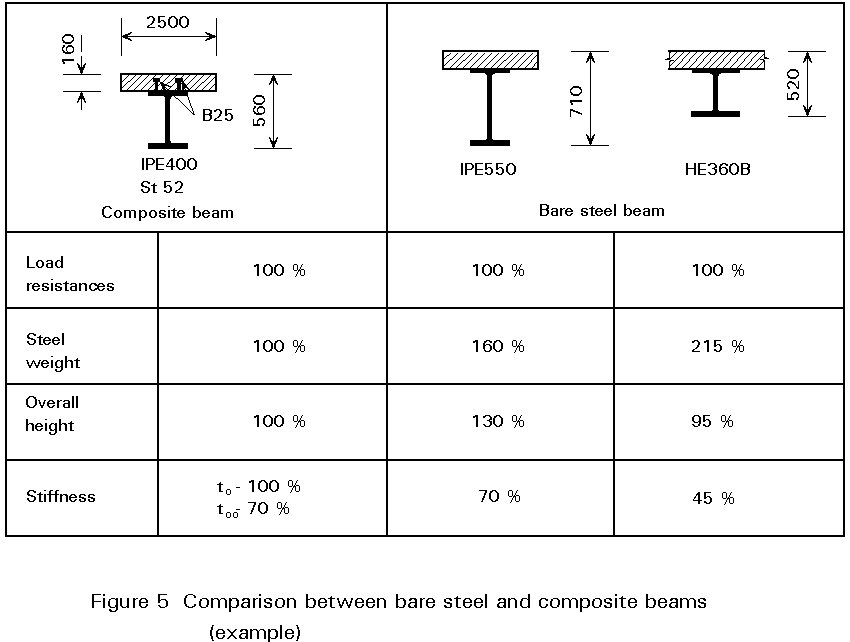

Single composite elements, such as isolated beams, columns and slabs (Figure 1), whilst they are of high quality and resistance, they are also, in many cases, expensive. This is the case particularly for buildings with small column spacings, floor beam spans well below 9 m and low loadings. On the other hand, composite floor construction is highly competitive if spans are increased to 12, 15 or even 20 m. There is, of course, a demand for larger column-free spans in buildings to facilitate open planning or greater flexibility in office layout, as shown in Figure 2.

A further important consideration is that the use of rolled steel sections, profiled metal decking and/or prefabricated composite members speeds up execution. For maximum efficiency and economy the joints should be cheap to fabricate and straightforward to erect on site.

Many experts feel that the further development of steel framed buildings depends largely on the use of composite construction. Unfortunately these two important building materials, steel and concrete, are promoted by two different industries. Since these industries are in direct competition with each other, it is sometimes difficult to promote the best use of the two materials.

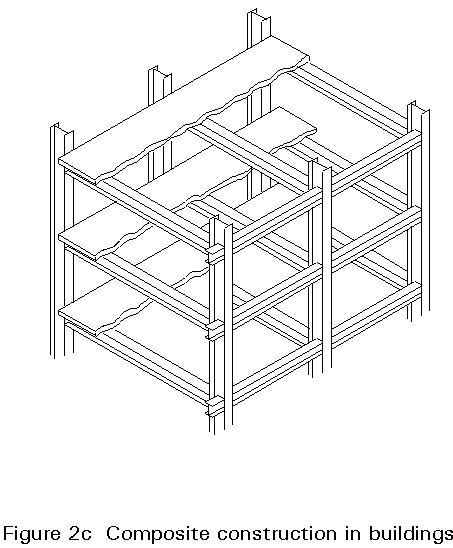

Figure 2 shows three examples of the use of composite floor construction comprising steel beams and concrete slabs, in buildings: Figure 2a shows a typical office building with offices on both sides of the corridor, the walls of which are defined by the positions of the internal columns; Figure 2b shows a large span, column-free structure, which allows a high amount of flexibility; the structure in Figure 2c has a reduced number of columns, with main and secondary beams.

Composite beams, subject mainly to bending, consist of a steel section acting compositely with one (or two) flanges of reinforced concrete. The two materials are interconnected by means of mechanical shear connectors. It is current European practice to achieve this connection by means of headed studs, semi-automatically welded to the steel flange, see Slide 4.

Slide 4 : Composite beams, subject mainly to bending, consist of a steel section acting compositely with one (or two) flanges of reinforced concrete.

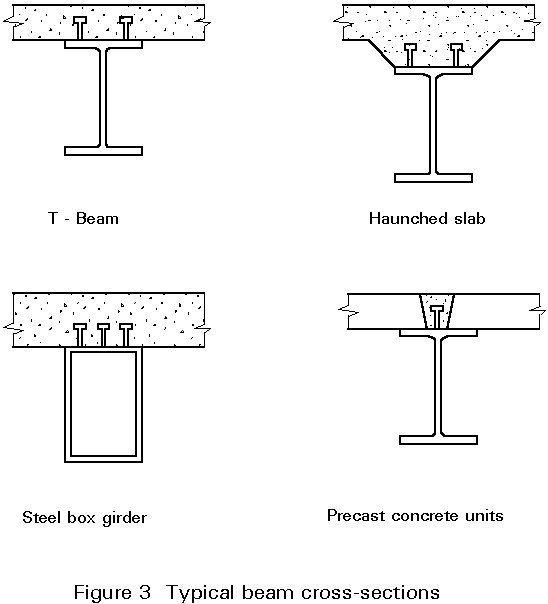

Figure 3 shows several composite beam cross-sections in which the wet concrete has been cast in situ on timber shuttering. For single span beams, sagging bending moments, due to applied vertical loads, cause tensile forces in the steel section and compression in the concrete deck thereby making optimum use of each material. Therefore, composite beams, even with small steel sections, have high stiffness and can carry heavy loads on long spans.

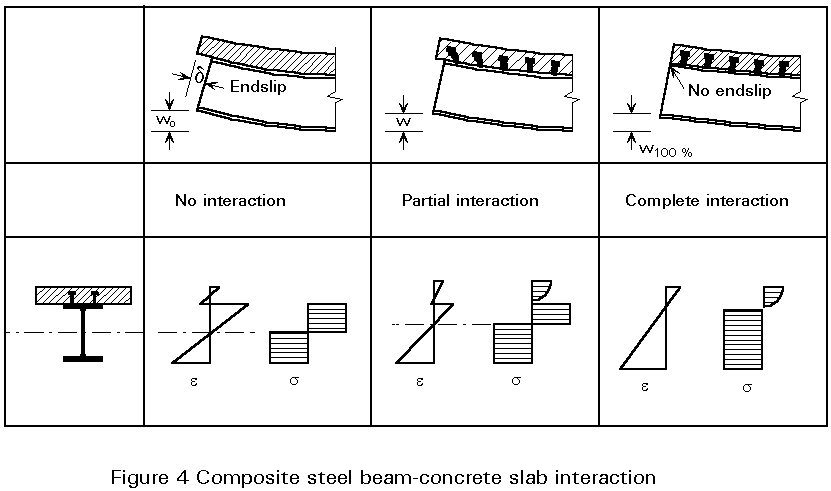

If slip is free to occur at the interface between the steel section and the concrete slab, each component will act independently, as shown in Figure 4. If slip at the interface is eliminated, or at least reduced, the slab and the steel member will act together as a composite unit. The resulting increase in resistance will depend on the extent to which slip is prevented. It should be noted that Figure 4 refers to the use of headed stud shear connectors. The degree of interaction depends mainly on the degree of shear connection used.

The following definitions are used to make clear the differences between resistance (strength) and stiffness properties:

Figure 3 shows the use of different shapes and types of steel beam (rolled or welded sections) together with in situ concrete.

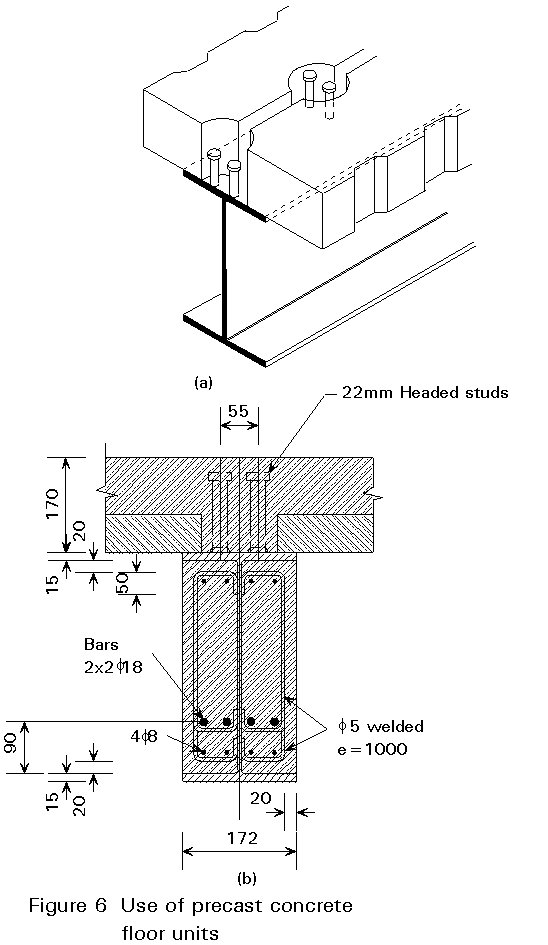

Instead of an in situ concrete slab, precast concrete floor or deck units can be used, see Figure 6. Careful detailing and construction practice are needed to ensure adequate containment for the connectors. Figure 6a shows a system using large prefabricated deck elements with longitudinal joints. The gaps between the units would be filled with mortar in the final structure, thereby giving composite action with the beams. Such structural systems were introduced during the early 1960's. In Germany more than 100 car parks, university, school and office buildings (see Slide 5) have been built in this way. The use of precast deck units reduces on-site construction operations and avoids wet trades. The units themselves are cast on steel formwork in a shop to ensure high quality and small (strict) tolerances.

Slide 5 : Instead of an in situ concrete slab, precast concrete floor or deck units can be used.

Figure 6b shows thin prefabricated concrete elements, supported by the steel beam flange. These elements act as permanent formwork when casting the in situ concrete. The transverse distances between the stud shanks and the edge of the prefabricated concrete element may be small however, making it difficult to ensure adequate containment for the connectors. The main reason for the use of these thin plate elements (usually 4-5cm thick) is that they are easy to handle, and almost as convenient to handle as metal decking.

Figure 6b also shows a partly encased composite beam, the voids of which are filled with concrete. This type of composite section is often used in parts of Europe today, in order to enhance the fire resistance rating without additional protection measures. The lower steel flange remains unprotected.

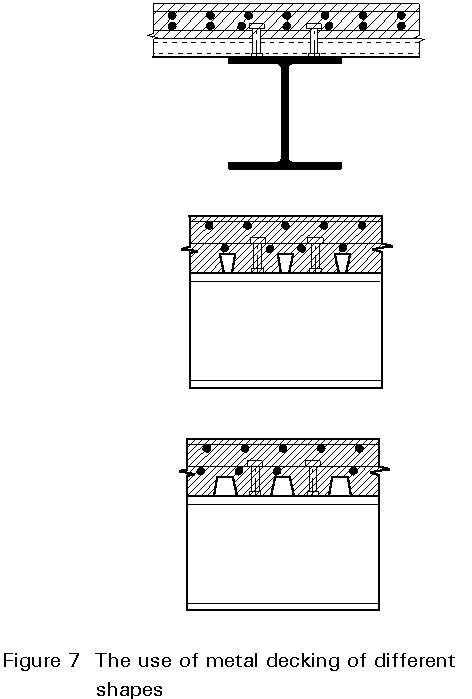

The usual practice however, in the case of commercial and industrial buildings (see Slide 6), is to construct the floors using metal decking which incorporates additional embossments or indentations to provide composite action. This is a very economical way to speed up construction, and is an important part of modern structural systems. The deck supports the loads developed before and during concreting and later acts compositely with the in situ concrete. Steel decking with re-entrant and trapezoidal profiles are typically used, see Figures 7 and 15.

Slide 6 : The usual practice for commercial and industrial buildings is to construct the floors using metal decking which is embossed to provide composite action.

Composite beams do not need any falsework or timber shuttering. This advantage is considered in the following section together with two different construction methods, "propped" and "unpropped".

The efficiency in structural performance will be greatest if it is possible to ensure that the concrete slab and steel member act compositely at all times. For this purpose, all loads, including the dead weight of the structure, should be resisted by the composite section. This requirement can be met by supporting the steel beam until the concrete has hardened. Such support is known as "propping". The number of temporary supports need not be high; propping at the quarter-span points and mid-span is generally sufficient. The props are left in place until the concrete slab has developed adequate resistance.

Different construction methods lead to different stress states, force distributions and deflections under service conditions. However, composite beams loaded up to failure fail at the same bending moment (assuming local instability is prevented) irrespective of whether propped or unpropped construction has been used. Their bending resistance can be easily calculated by means of rectangular stress blocks as outlined below.

A typical form of composite construction consists of a slab connected to a series of parallel steel members. The structural system is therefore essentially a series of interconnected T-beams with wide, thin concrete flanges as shown in Figure 2. In such a system, the flange width may not be fully effective in resisting compression due to "shear lag". This phenomenon, which is taken into account by the well known "effective width" approach, is explained later.

No account needs usually to be taken of local buckling in the steel section in simply supported composite beams, since the compression flange is attached to the concrete slab by shear connectors, and the depth of the web in compression is usually small. In the case of partial interaction however, the depth of the compressed part of the web is greater. In this case, therefore, there remains at least theoretically the possibility that local buckling could occur in the web of a deep plate girder or in a flange with a wide outstand beyond the shear connectors.

The dimensions of most steel beam sections in buildings are such that plastic analysis can be applied to the cross-section of the composite beam. The calculation of the ultimate moment of resistance is, therefore, an application of the rectangular stress block diagram on the assumption that the steel sections belong to Class 1 or 2.

Many composite beams in buildings are - from the point of view of the static calculation -continuous beams over simple supports. The concrete slabs are also usually continuous since they are cast without joints. Continuous beams in comparison with single span beams, therefore, have the following advantages:

On the other hand, the continuity can complicate the design, particularly in regard to lateral-torsional and local buckling in negative moment regions. Local buckling of steel can reduce the bending resistance of the section below the plastic moment, unless certain limitations to the breadth/thickness ratios of the elements making up the section are met. Based on these ratios steel sections are grouped in Classes 1 to 4: Class 1 sections allow for global plastic analysis, using moment redistribution, which gives a very economic design; Class 2 sections allow for plastic calculation of the moment of resistance but do not permit redistribution. Hot rolled sections conform to Class 1 or 2 in most cases and when they are used local buckling is not, therefore, a problem.

Adequately proportioned anti-crack reinforcement should be provided in the concrete slab over interior supports where joints are not present. If the reinforcing bars have enough ductility they will increase the bending resistance substantially in these hogging moment regions.

Mechanical connectors are used to develop the composite action between steel beams and concrete. This connection is provided mainly to resist longitudinal shear, and is referred to as the "shear connection".

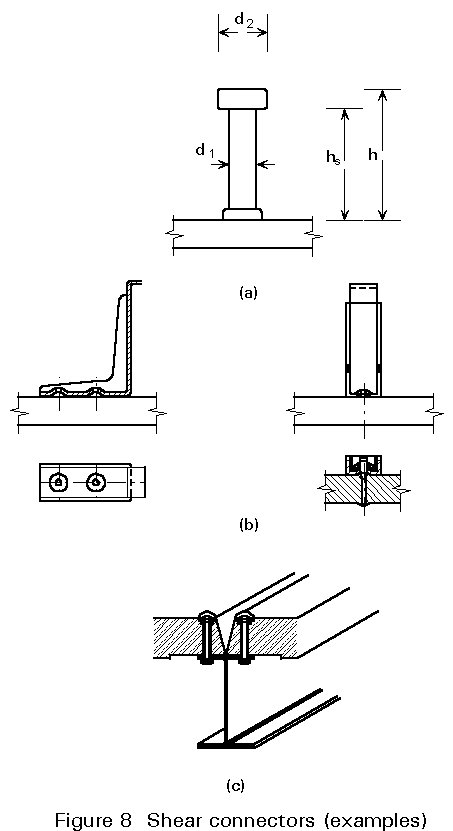

Figure 8 shows several types of shear connectors. They have to fulfil a number of requirements, as follows:

In the industrialised countries the most common connector is the headed stud. It can be welded semi-automatically (see Slide 4) to the upper flange either directly in the shop or through thin galvanised steel sheeting on site (see Figure 8a).

Shot fired connectors, as shown in Figure 8b, have been used as an alternative in cases where metal decking is used and sufficient electrical power is not available on site. These connectors have the advantage that modified cartridge guns can be used instead of the special equipment required for complex through-deck welding.

In the case of prefabricated concrete deck units preloaded high strength bolts have sometimes been used to connect them to the beams, see Figure 8c. This type of connection has been used, for example, in temporary car parks because the connection can be removed (although all such existing car parks are in permanent use at the present time).

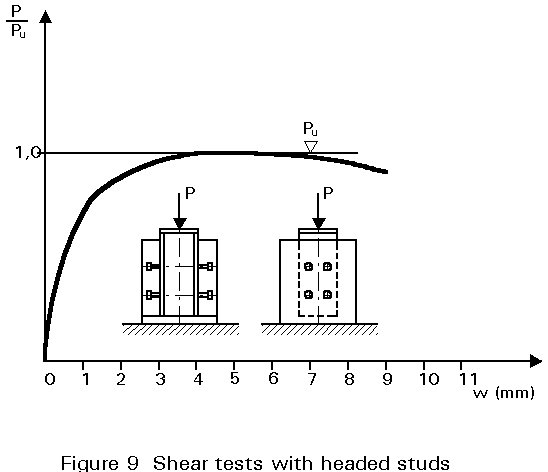

The behaviour and resistance of headed studs and other connectors are examined by means of "shear" or "push out" tests. These tests yield load-slip curves such as is shown in Figure 9 for headed studs. The behaviour is characterised by great stiffness at low loading (under service conditions) and large deformations at high loadings up to failure. Such ductile behaviour makes shear force redistribution at the steel-concrete interface possible and allows for partial shear connection. In addition, headed studs may be spaced uniformly along the beam length between critical cross-sections.

Composite beams are often designed under the assumption that the unpropped steel beam supports the weight of the structural steel and wet concrete plus construction loads. It may, therefore, be decided for reasons of economy to provide only sufficient connectors to develop enough composite action to support the loads applied afterwards. This approach results in many less connectors than are required to enable the maximum bending resistance of the composite beam to be reached. The use of such partial shear connection results in reduced resistance and stiffness.

Partial shear connection may be unavoidable when a slab is constructed with metal decking. The number of shear connectors attached to the steel beam may then be limited by the restriction of being able to place them only in the troughs of the profiled steel sheeting.

Highly developed connection techniques can be used for connecting together structural steel members. Economy requires, however, that the joints are economic to fabricate and straightforward to install on site. Studies have indicated that the cost effectiveness of composite structures may be improved, if the actual degree of continuity provided by nominally simple joints is recognised in design.

In composite steel-concrete structures, however, significant additional stiffness and resistance can be provided simply by placing continuous reinforcing bars in the slab around the columns, since the single major factor governing the behaviour of joints is the slab action.

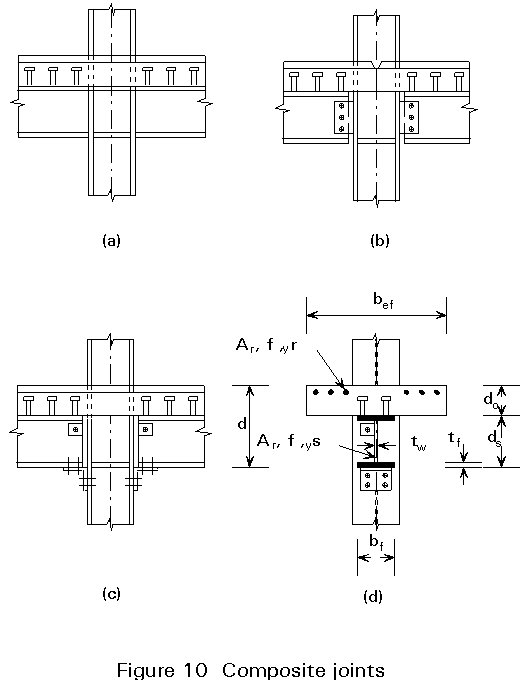

This effect can be augmented by a special sequence of construction and concreting, as follows: during concreting the steel section acts as a single span beam; the beam should be connected to the steel column by means of double web angles or flange cleats with or without web angles; after the concrete has hardened (assuming it is without joints as shown in Figure 10c) it is considered as a continuous beam supporting the additional applied loads. By following this construction sequence, the required bending moment redistribution is not extensive and plastic rotation can be significantly reduced. In addition the designer can take the decision whether or not to use shims between the steel compression flange and the column mainly depending upon the plastic end moment of the joint.

Figure 10 compares simple, rigid and semi-rigid composite joints. The construction detail without shims, shown in Figure 10c, is consistent with the growing interest in flexibly connected (semi-rigid) steel frames with simple construction details which speed up construction. It is proposed that the following performance criteria should be met:

Beam-to-column connections in tall buildings demand somewhat different solutions. Until recently such structural systems employed only simple shear connections between structural steel and reinforced concrete elements. However, mixed structures should also be considered which are built by first erecting a frame of light steel columns and deep spandrel beams. The steel columns are later encased by reinforced concrete.

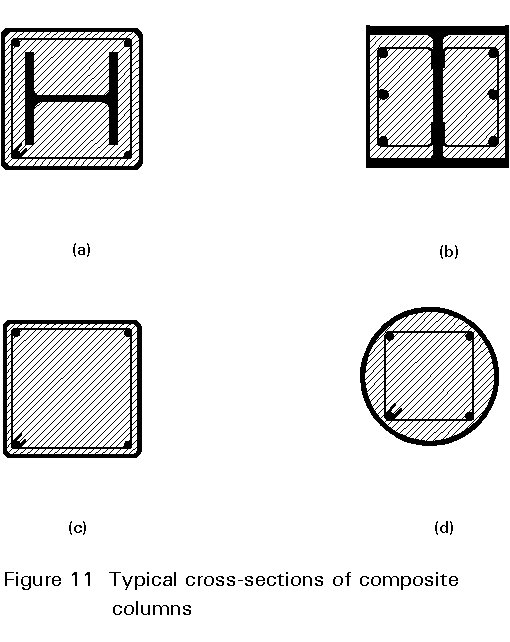

Three different types of composite columns are principally in use, see Figure 11:

In calculating the strength of such columns, full composite interaction without any slip at the steel-concrete-interface is assumed. Strictly speaking all geometrical and physical non-linearities of the different materials should be observed. It is only possible, however, to meet these requirements by using comprehensive numerical methods of analysis and computer software. The assumed complete interaction enables definition of section properties, and stiffness and slenderness ratios, for the whole inhomogeneous cross-section. This information is necessary to determine the load carrying resistance, including slenderness or P-D-effects. Eurocode 4 gives simplified design methods for practical use. Instead of more precise buckling curves, Eurocode 4 [1] has adopted the European buckling curves a,b and c which were originally established for bare steel columns.

The complete interaction must be ensured by means of mechanical connections. The connections have to be provided at least at the column ends and where loads or forces are acting. They should be distributed over the whole cross-section. Such connectors can be headed studs, top and bottom plates, suitable brackets, vertical gusset plates, shear heads or other structural means.

Concrete encased columns have the advantage that they meet fire resistance requirements without any other protection. In addition, they can be easily strengthened by reinforcing bars in the concrete cover. They do not, however, present an accessible structural steel surface for later fastenings and attractive surface treatment. In the case of prefabricated encased columns, the structural steel sections are fabricated in a workshop and include all welds, connection plates and other necessary attachments. These steel columns (the longest have been up to 30 m long) can then be transported to another workshop, where concreting takes place. After the concrete encasement has cured the completed columns can be brought to the construction site.

Concrete filled steel tubes are also in use. The tubes are generally filled with high strength concrete, with a minimum cube strength of 45 to 55N/mm2. These strengths, however, are far below those which have been developed recently in North America.

If the bearing forces from the floor beams are transferred by means of vertical connection plates, these plates run through the tube and are welded on both sides. This welding ensures both parts, the steel tube as well as the concrete core, are loaded directly without excessive slip at the steel-concrete interface. In order to meet the required fire resistance rating, the concrete core must be longitudinally reinforced. It is impossible, however, to take advantage of the full column resistance in many cases.

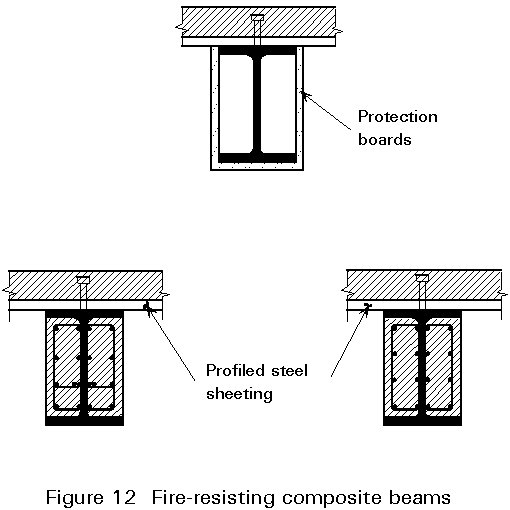

Partially encased steel sections, for both beams and columns, are an interesting development of the last 10 years. The most important feature of such a partially encased section is its inherent high fire resistance. The fire resistance is due to the fact that the concrete part prevents the inner steel parts - structural steel as well as reinforcing bars - from heating up too fast. Figure 12 shows two partly encased composite beams (on the right hand side) compared with conventional fire protection by means of boards. Slide 7 shows a typical composite floor construction, where partly encased sections are used; no further fire protection for beams and slabs is necessary.

Slide 7 : Partially encased steel sections, for both beams and columns, are an interesting development of he last ten years.

The concrete parts are cast in a workshop or on site before erection. This procedure enables rapid construction with prefabricated composite members. The concrete between the flanges should be reinforced by longitudinal bars and stirrups, and should be attached to the web by stud connectors, welded bars, or bars through holes.

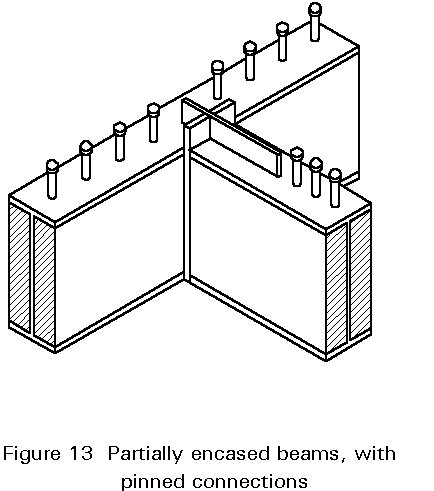

In addition to the enhanced fire resistance, crippling and local buckling of the steel web is prevented and the resistance of the steel beam against lateral-torsional buckling is significantly increased. These beams also have greater stiffness under bending and vertical shear which results in a reduction of final deflection. They look very massive, as can be seen from Figure 13, and are characterised by their free bottom flange, to which ducts, other services and plant can be clamped or fastened.

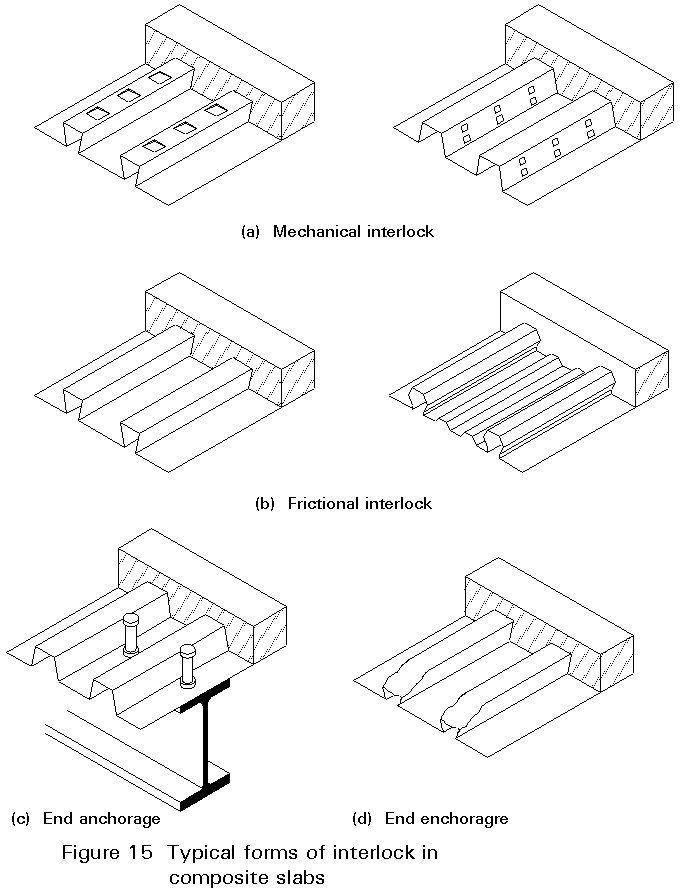

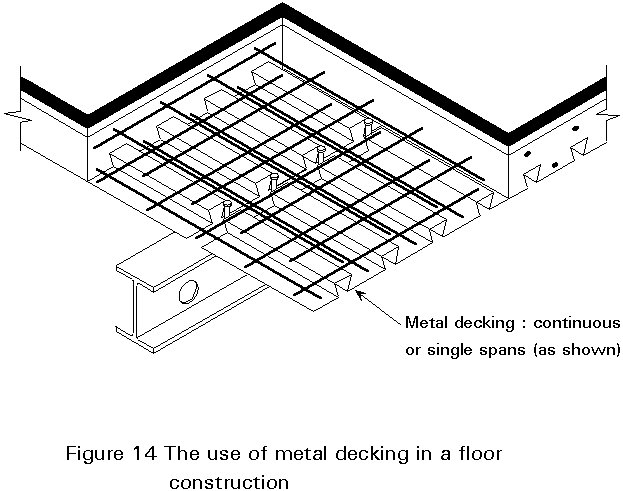

In floor construction, the use of the solid reinforced concrete slab is being replaced more and more by metal decking, see Figure 14. Modern profiled steel sheeting with additional indentations or embossments acts as both permanent formwork during concreting and tension reinforcement after the concrete has hardened. At this final stage the composite slab consists of a profiled steel sheet and an upper concrete topping which are interconnected in such a manner that horizontal shear forces can be resisted at the steel-concrete interface. Slip (relative displacements) at the interface must be prevented completely or partly, as should vertical separation of the steel decking from the concrete topping.

The required composite action can be achieved by various means, see Figure 15. To allow for the large variety of current and possible future products on the market Eurocode 4 permits the following methods of achieving shear load:

a. mechanical interlock provided by deformations in the profile (indentations or embossments).

b. frictional interlock for profiles shaped in a re-entrant form.

c. end anchorage provided by welded studs or shot fired shear connectors.

d. end anchorages by deformation of the ribs at the end of the sheeting in combination with (b).

The use of profiled steel sheeting undoubtedly speeds up construction. It is also often used with lightweight concrete to reduce the dead load due to floor construction. In the UK, for example, this use of lightweight concrete is common practice for commercial buildings.

The composite slabs are supported by steel beams, which normally act compositely with the concrete slab. The spacing of the beams, and therefore the slab span, depends on the method of construction, as follows:

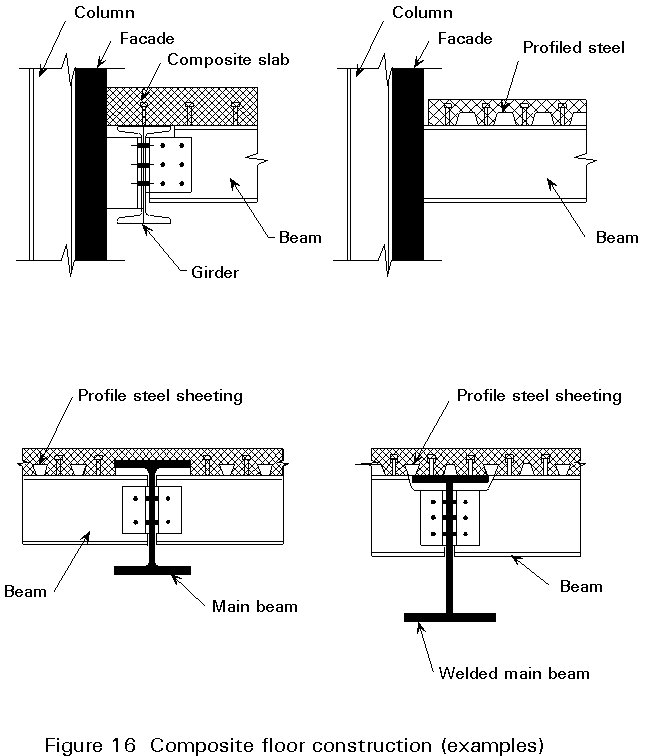

Composite floor construction is essentially an overlay of one-way structural elements. The slabs span between the secondary or floor beams, which span transversely between the primary beams. The latter in turn span onto the columns, see Figure 16, Slides 1 and 2. This set of load paths leads to rectangular grids, with large spans in at least one direction (up to 12, 15 or even 20 m). Up to 15 m, rolled sections are mainly used, while from 12 m upwards welded plate girders, stub girders or truss girders tend to be more economical.

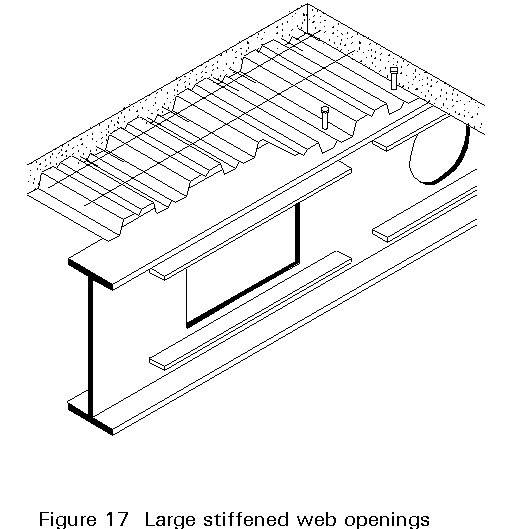

During the life of a structure changes in use must be expected. Whilst many of these changes affect service requirements, others will primarily affect layout. The best way to maximise flexibility of internal planning is to minimise the number of columns. Figure 2 shows typical examples of ways in which primary beams of larger span, can reduce or eliminate internal columns. These large span beams may be so deep that services can only be accommodated by providing holes in the primary webs, see Figure 17. Stiffening around the openings may be necessary, particularly in the presence of very high vertical shear forces.

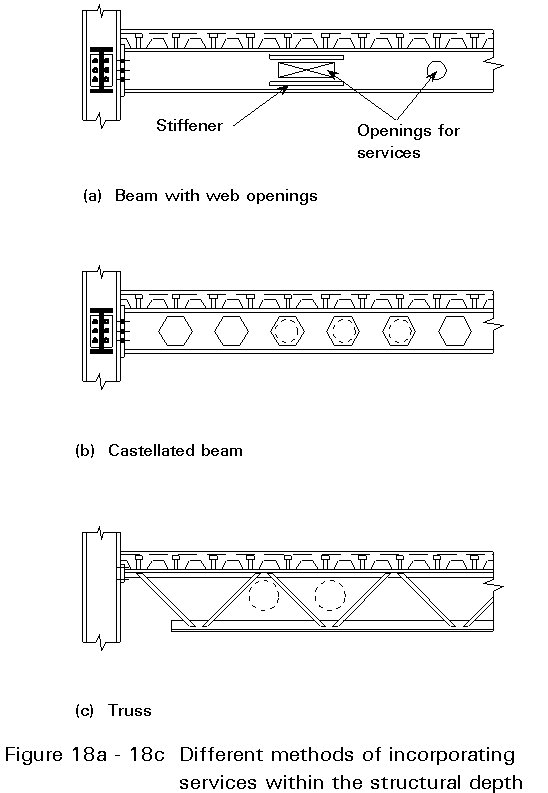

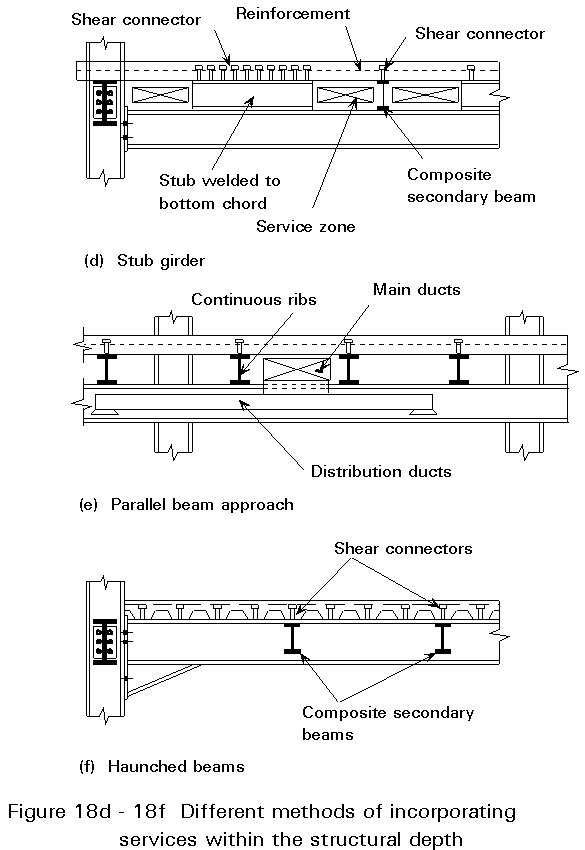

Other methods of incorporating services within the structural depth are shown in Figure 18. One additional alternative is the possibility of tapering the beams near to their ends.

In the case of longer span floors, the designer may need to consider the susceptibility of the floor structure to vibration. The parameter commonly associated with this effect is the natural frequency of the floor: the lower the natural frequency, the more the structure may respond dynamically to occupant- induced vibration.

For this purpose floors (or beams) are normally designed to have a natural frequency not less than 3Hz, and in the case of floors that may be subject to rhythmic group activities, not less than 4Hz. An alternative more precise approach is to assess the likely vibrational behaviour and, taking into account the human reaction to vibration, thereby establish acceptance criteria.

In summary, composite floor construction used for commercial and other multi-storey buildings, offers the following main advantages to the designer and client:

Composite beams are designed using plastic design methods and partial interaction theory, combining steel and concrete to great effect. To obtain maximum advantage from this form of construction, planning and design should be integrated from the start. The involvement of experienced site managers at an early stage will help avoid problems later on. With this carefully planned approach, different operations such as steel erection, metal decking and stud welding, concreting, fire protection, cladding, facade work, services and finishing can be carried out at different floor levels simultaneously.

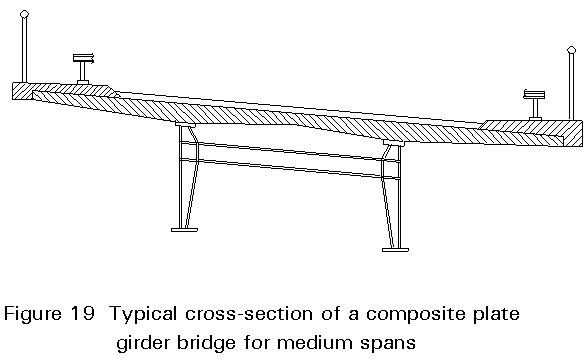

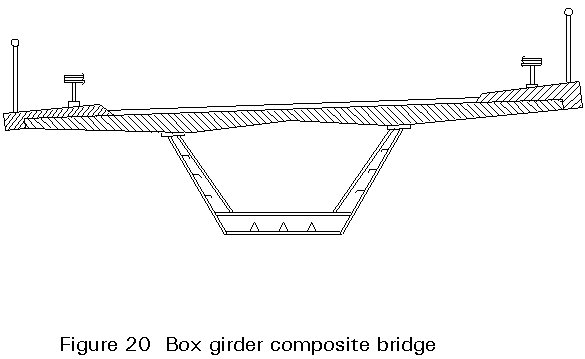

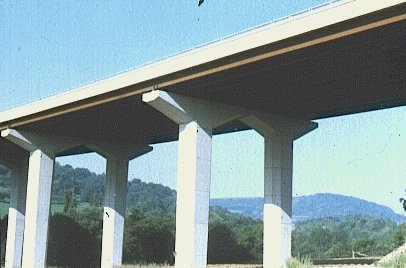

Medium span composite bridges are normally constructed from welded, built up, steel plate girders and a wide reinforced concrete deck, as shown in Figure 19. Box girders, see Figure 20, which look very attractive but which are more expensive, are used less frequently. For the smaller spans, from 20 up to 35m, rolled steel sections are more popular. They can be used with a concrete deck slab or embedded in concrete (upper flange and web). Slide 8 gives an illustration of rolled sections, which can be fabricated curved if required, used in this way.

Slide 8 : Medium span composite bridges are normally constructed from welded, built up, steel plate girders and a wide reinforced concrete deck.

Since the 1950's, several large span continuous composite highway bridges have been erected. During the years immediately after World War II, structural steel was very expensive, and advantage was taken of the light composite cross-section to save material costs. The sections of today are more compact and simpler, and do not have so many secondary beams, bracings and stiffeners. This form of structure saves labour costs in the workshop as well as on the construction site.

Due to the unsymmetrical nature of the cross-section, concrete shrinkage always causes compression and positive bending in the steel section leading to greater deflections.

In propped construction the compression in the concrete flange due to the self weight of the beam causes creep deformations. The concrete sheds compression. Stresses and forces are then redistributed from the concrete flange to the steel beam, and the steel beam, therefore, has to resist a greater part of the loading. This redistribution also results in increased deflections.

A simple way to take creep and shrinkage effects into account is to reduce the stiffness of the concrete by means of appropriate reduction coefficients "n". These n-factors depend not only on duration and time of loading after concreting, but also on the cross-section properties and the environmental conditions. It should be noted that this procedure does not apply to beams in buildings, where less precision is required.

At the ultimate limit state strains due to load are much larger than the strains due to creep and shrinkage, and the latter can therefore be neglected.

The design considerations for composite bridges are discussed further in Lecture 10.10.

[1] Eurocode 4: "Design of Composite Steel and Concrete Structures:" ENV 1994-1-1: Part 1.1: General rules and rules for buildings, CEN (in press).